In-situ leaching uranium mining full-process circulation experimental device

An experimental device and in-situ leaching uranium mining technology are applied in the field of in-situ leaching and mining uranium full-process cycle experimental devices, which can solve the problems of long time, large leaching liquid-solid ratio, only tens of milliliters to hundreds of milliliters, etc., and achieves convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

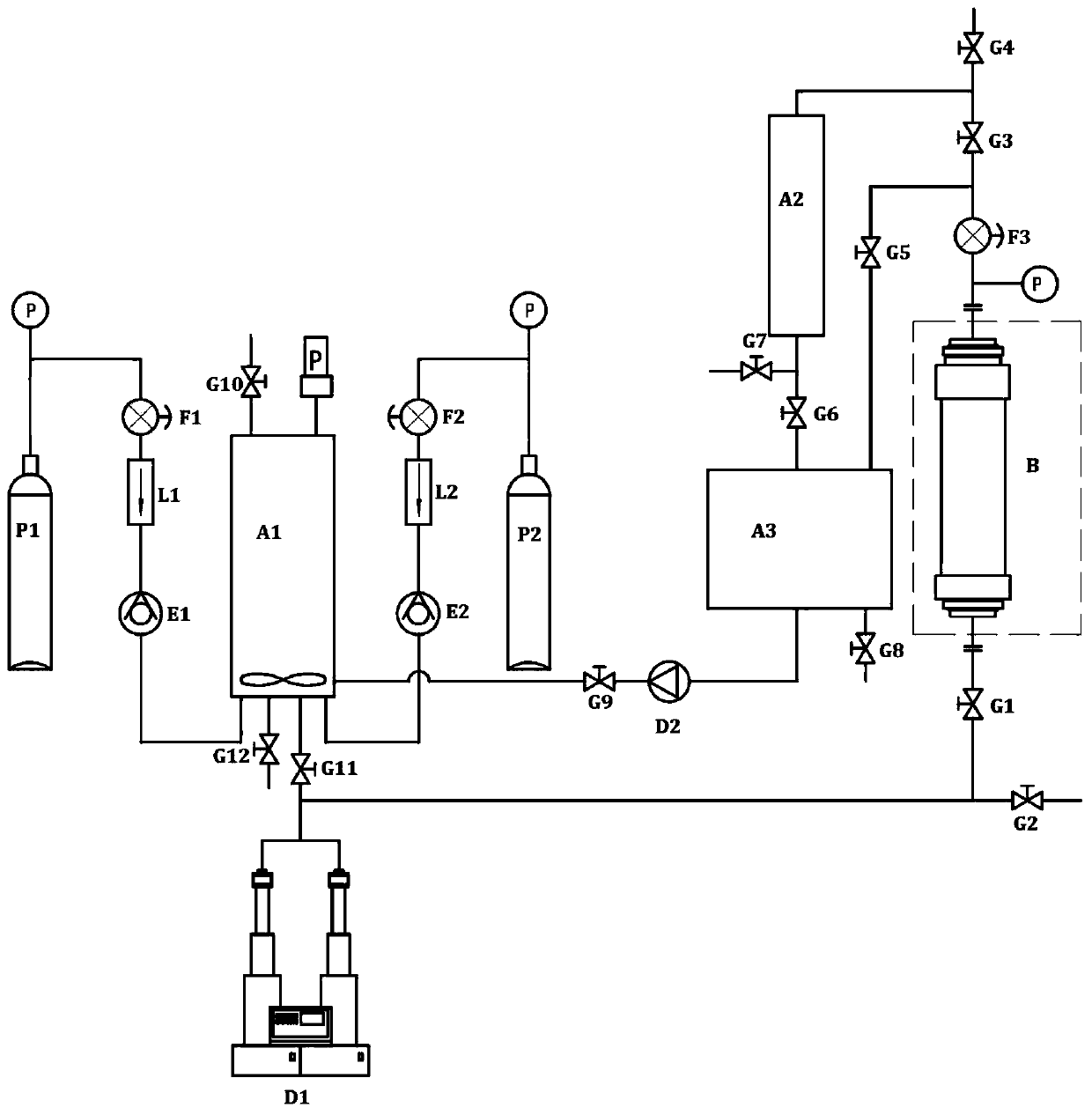

[0023] Such as figure 1 As shown, the composition and connection relationship of the in-situ leaching uranium full-process circulation experimental device of the present invention are as follows: the constant-speed constant-pressure double-cylinder pump D1 is connected to the high-pressure test column B through the leaching agent inlet valve G1, and the high-pressure test column B The outlet is equipped with a column leaching outlet pressure regulating valve F3, and the column leaching outlet pressure regulating valve F3 is connected to the upper part of the ion exchange column A2 after passing through the leaching liquid outlet valve G3, and the lower part of the ion exchange column A2 is connected to the liquid collection tank A3 through the adsorption tail liquid valve G6, The liquid collecting tank A3 is connected to the stirring tank A1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com