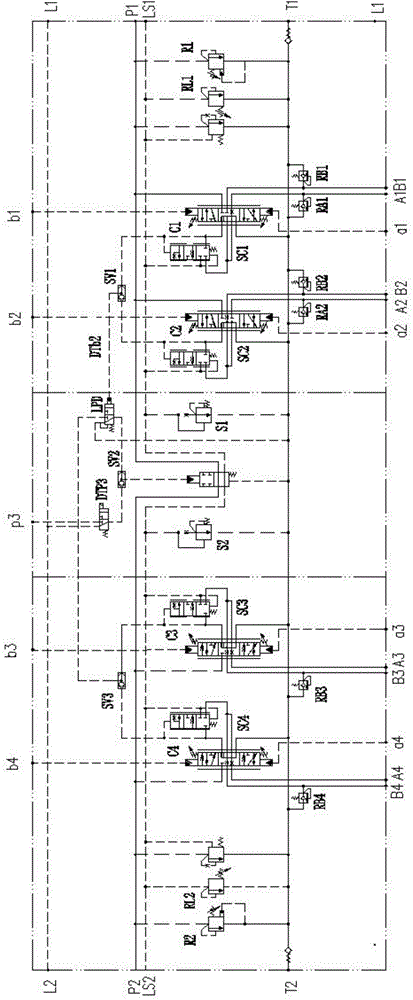

Valve back compensation type load-sensitive multitandem valve with bidirectional confluence function

A load-sensing, post-valve compensation technology, applied in the field of multi-way valves, can solve problems such as limiting the scope of use, achieve the effects of convenient maintenance, replacement and debugging, rapid action, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

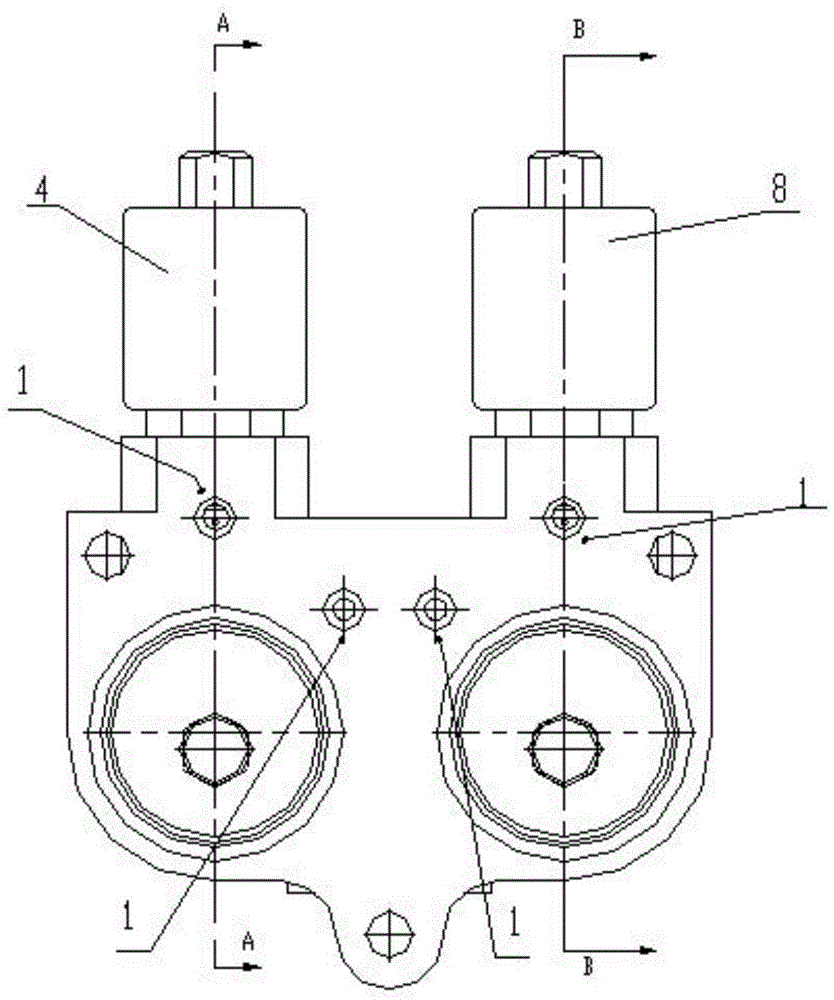

[0033] like figure 1 and figure 2As shown, a post-valve compensation load-sensing multi-way valve with two-way confluence includes a confluence union and two oil inlet working unions located at both ends of the confluence union. The confluence union is a confluence valve with two-way confluence function, including an electromagnetic Valve DTP3, hydraulic control valve LPD, shuttle valve IISV2 and electro-hydraulic joint control confluence switching valve PS, the input end of the solenoid valve DTP3 communicates with the confluence external control pressure input port P3, and the output end communicates with the input end of the shuttle valve IISV2; The pilot control terminal of the hydraulic control valve LPD communicates with the shuttle valve ISV1 and the oil return circuit T respectively, the input terminal communicates with the shuttle valve IIISV3 and the oil re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com