Environment-friendly cleaning and repairing agent for composite insulator

A technology of composite insulators and repairing agents, applied in the directions of detergent compounding agents, detergent compositions, cleaning methods and utensils, etc., can solve the problems of easy adhesion to high-voltage equipment, residual ionic compounds, risks, etc., without affecting Insulation performance, enhanced cleaning performance, the effect of strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The components of the environmental protection cleaning and repairing agent for composite insulators in this embodiment include by weight percentage:

[0029]

[0030] The production method of the above-mentioned environmentally friendly cleaning and repairing agent for composite insulators includes the following steps:

[0031] (1) According to the design ratio, polyethylene glycol octyl phenyl ether and alkyl polyglucoside are fully dissolved in water to form a mixed solution;

[0032] (2) Add fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether, triethanolamine, diethylamino sulfur trifluoride successively, and stir evenly;

[0033] (3) Add methyl laurate and stir evenly to obtain an environmental protection cleaning and repairing agent for composite insulators.

[0034] When using the above composite insulator environmental protection cleaning and repairing agent, use a rag to soak in the solution and then scrub the surface of the insulator. Af...

Embodiment 2

[0036] The components of the environmental protection cleaning and repairing agent for composite insulators in this embodiment include by weight percentage:

[0037]

[0038]

[0039] The production method of the above-mentioned environmentally friendly cleaning and repairing agent for composite insulators includes the following steps:

[0040] (1) According to the design ratio, polyethylene glycol octylphenyl ether and trifluorotrichloroethane are fully dissolved in water to form a mixed solution;

[0041] (2) Add fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether, triethanolamine, diethylamino sulfur trifluoride successively, and stir evenly;

[0042] (3) Add methyl laurate and stir evenly to obtain an environmental protection cleaning and repairing agent for composite insulators.

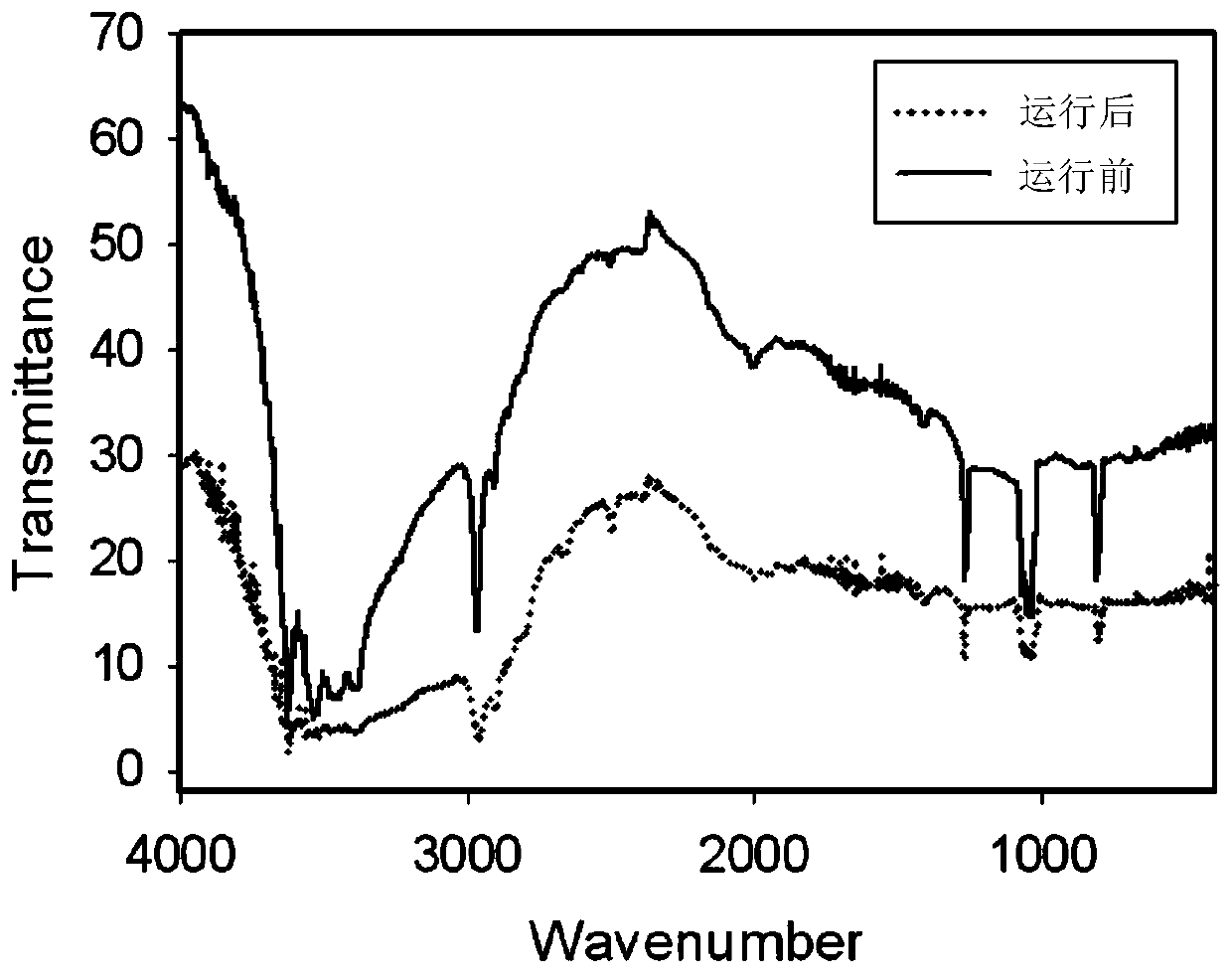

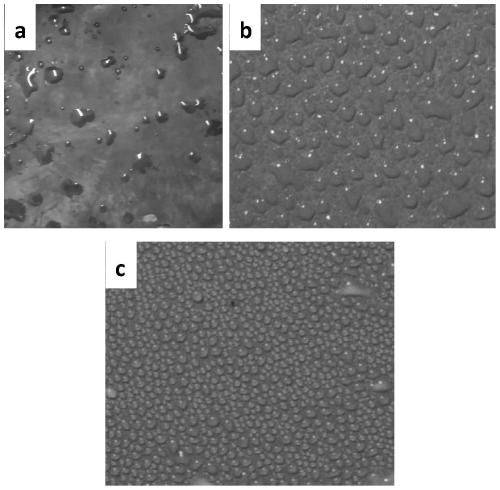

[0043] Such as figure 2 As shown, the comparison of RTV paint insulators before and after operation shows that the insulators have aged after operation.

[0044] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com