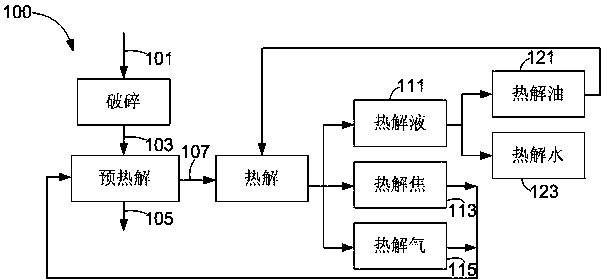

Method for preparing fuel oil through pyrolysis of waste non-setting adhesives

A waste and fuel oil technology, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, special forms of dry distillation, etc., can solve the problems of environmental pollution, waste of resources, occupation of land resources, etc. The effect of low system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

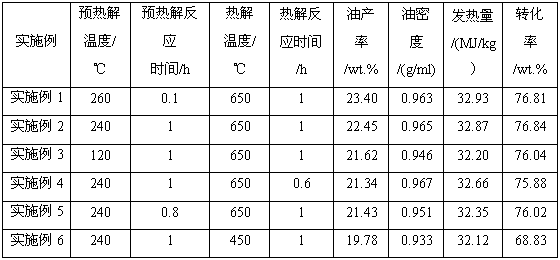

[0026] After crushing the self-adhesive waste 101, add 100g of the crushed self-adhesive waste 103 into the pyrolysis reactor through the feeder, start heating to the pre-pyrolysis temperature of 260°C, and after the pre-pyrolysis reaction time is 0.1h Afterwards, continue to heat up to the pyrolysis temperature of 650° C., and control the pyrolysis reaction time to 1 h. The pre-pyrolysis reaction product was condensed by a condensation tower to obtain 15.23 g of water 105 , and the pyrolysis product was condensed by a condensation tower to obtain 28.90 g of pyrolysis gas 115 , 9.28 g of pyrolysis water 123 and 23.40 g of pyrolysis oil 121 . Through pyrolysis, the conversion rate of self-adhesive waste raw materials is 76.81%, which well achieves the purpose of reducing solid waste; the yield of pyrolysis oil 121 reaches 23.40%, and the density is 0.963g / ml. The heat reaches 32.93MJ / kg.

specific Embodiment approach 2

[0028] After the self-adhesive waste 101 is crushed, add 100g of crushed self-adhesive waste 103 into the pyrolysis reactor through the feeder, start heating to the pre-pyrolysis temperature of 240°C, and after the pre-pyrolysis reaction time is 1h , continue to heat up to the pyrolysis temperature of 650°C, and control the pyrolysis reaction time to 1h. The pre-pyrolysis reaction product was condensed by a condensation tower to obtain 13.49 g of water 105 , and the pyrolysis product was condensed by a condensation tower to obtain 29.80 g of pyrolysis gas 115 , 11.10 g of pyrolysis water 123 and 22.45 g of pyrolysis oil 121 . Through pyrolysis, the pyrolysis conversion rate of self-adhesive waste raw materials is 76.84%, which well achieves the purpose of solid waste reduction; the yield of pyrolysis oil 121 reaches 22.45%, and the density is 0.965g / ml , the calorific value reaches 32.87MJ / kg.

specific Embodiment approach 3

[0030] After the self-adhesive waste 101 is crushed, add 100g of crushed self-adhesive waste 103 into the pyrolysis reactor through the feeder, start heating to the pre-pyrolysis temperature of 120°C, and after the pre-pyrolysis reaction time is 1h , continue to heat up to the pyrolysis temperature of 650°C, and control the pyrolysis reaction time to 1h. The prepyrolysis reaction product was condensed by the condensation tower to obtain 13.10 g of water 105 , and the pyrolysis product was condensed by the condensation tower to obtain 29.84 g of pyrolysis gas 115 , 11.48 g of pyrolysis water 123 and 21.62 g of pyrolysis oil 121 . Through pyrolysis, the conversion rate of self-adhesive waste raw materials was 76.04%, which achieved the goal of solid waste reduction; the yield of pyrolysis oil 121 reached 21.62%, and the density was 0.946g / ml. The heat reaches 32.20MJ / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com