Method for producing degradable seedling raising paper container by utilizing fir leftover materials and branch wood pulp

A technology for leftovers and seedling paper, applied in pulp beating method, paper making, application, etc., can solve problems such as limited source of raw materials for seedling paper containers, and achieve the effects of being beneficial to ecological environmental protection and market economy, broadening sources, and alleviating supply shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

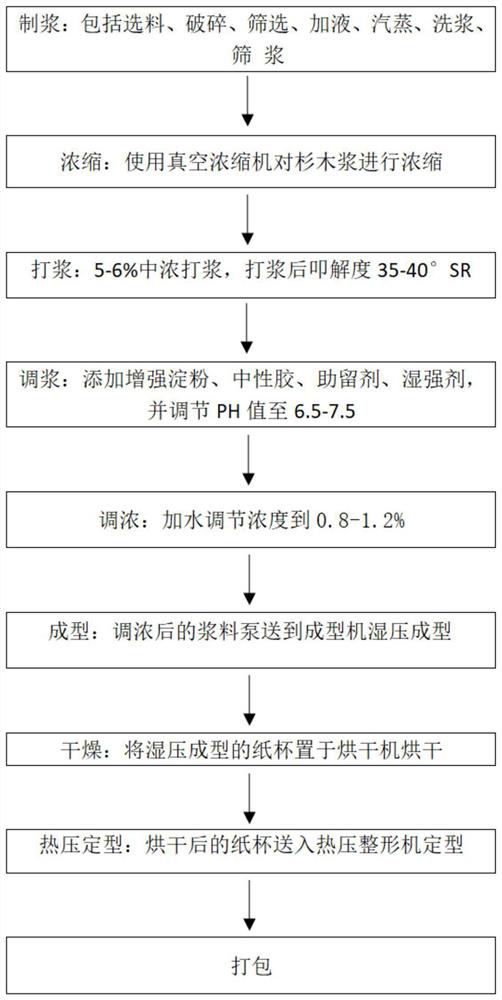

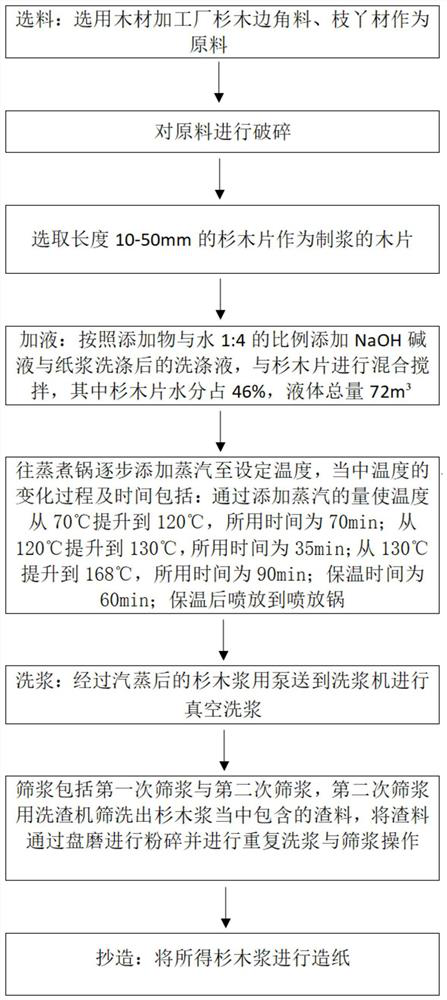

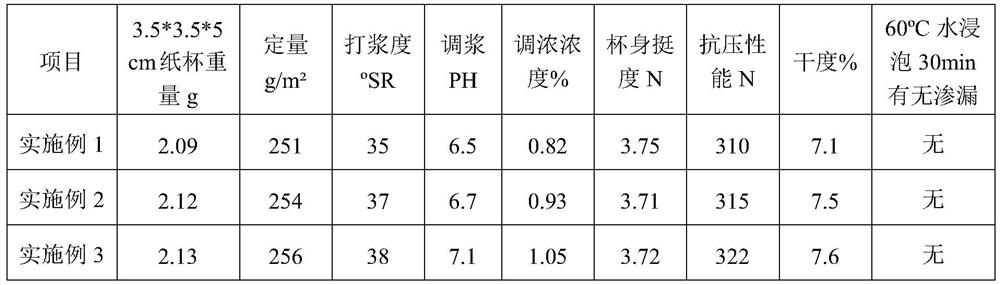

[0067] like figure 1 , figure 2 , shown in table 1: choose cheap, source the Chinese fir leftovers and branches of wood processing plants with wide range of sources as the basic raw material of fir pulp; enter the cooking pot after crushing and screening the qualified Chinese fir chips of 10-50mm; before cooking, according to the additives The ratio of water weight to 1:4 is mixed with the washing liquid after pulp washing and fir chips, of which the water content of fir chips accounts for 46%; gradually add steam to the cooking pot to the set temperature, and the temperature change process and time Including: increasing the temperature from 70°C to 120°C by adding the amount of steam, and the time used is 70 minutes; from 120°C to 130°C, the time used is 35 minutes; from 130°C to 168°C, the time used is 90 minutes; holding time 60 minutes; after heat preservation, it is sprayed into the spray pot; after steaming, the Chinese fir pulp is pumped to the pulp washer for vacuum ...

Embodiment 2

[0070] like figure 1 , figure 2 , shown in table 1: choose cheap, source the Chinese fir leftovers and branches of wood processing plants with wide range of sources as the basic raw material of fir pulp; enter the cooking pot after crushing and screening the qualified Chinese fir chips of 10-50mm; before cooking, according to the additives The ratio of water weight to 1:4 is mixed with the washing liquid after pulp washing and fir chips, of which the water content of fir chips accounts for 46%; gradually add steam to the cooking pot to the set temperature, and the temperature change process and time Including: increasing the temperature from 70°C to 120°C by adding the amount of steam, and the time used is 70 minutes; from 120°C to 130°C, the time used is 35 minutes; from 130°C to 168°C, the time used is 90 minutes; holding time 60 minutes; after heat preservation, it is sprayed into the spray pot; after steaming, the Chinese fir pulp is pumped to the pulp washer for vacuum ...

Embodiment 3

[0073] like figure 1 , figure 2 , shown in table 1: choose cheap, source the Chinese fir leftovers and branches of wood processing plants with wide range of sources as the basic raw material of fir pulp; enter the cooking pot after crushing and screening the qualified Chinese fir chips of 10-50mm; before cooking, according to the additives The ratio of water weight to 1:4 is mixed with the washing liquid after pulp washing and fir chips, of which the water content of fir chips accounts for 46%; gradually add steam to the cooking pot to the set temperature, and the temperature change process and time Including: increasing the temperature from 70°C to 120°C by adding the amount of steam, and the time used is 70 minutes; from 120°C to 130°C, the time used is 35 minutes; from 130°C to 168°C, the time used is 90 minutes; holding time 60 minutes; after heat preservation, it is sprayed into the spray pot; after steaming, the Chinese fir pulp is pumped to the pulp washer for vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com