A mining method with strip coal pillars left

A technology of strip coal pillar and mining method, which is applied in the directions of surface mining, earthwork drilling, underground mining, etc., can solve the problems of low recovery rate of coal resources, shortage of coal resources, waste of coal resources, etc. The effect of improving recovery rate and easing supply shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

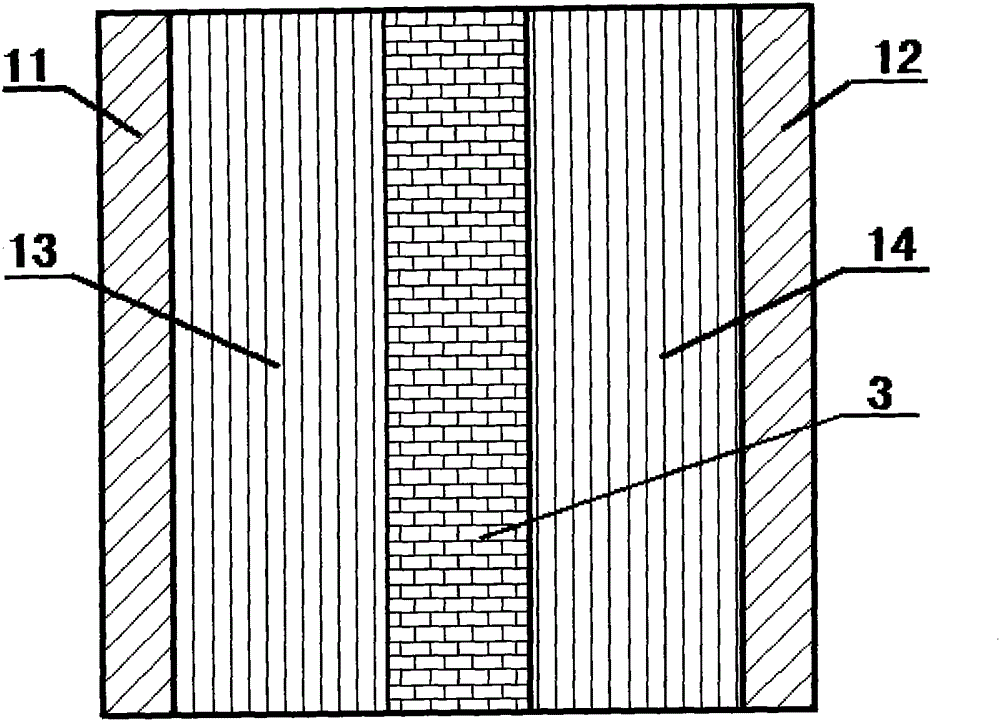

[0015] The present invention adopts the method of mining and filling the middle of the protected coal pillar first, and then mining on both sides. The specific steps are as follows:

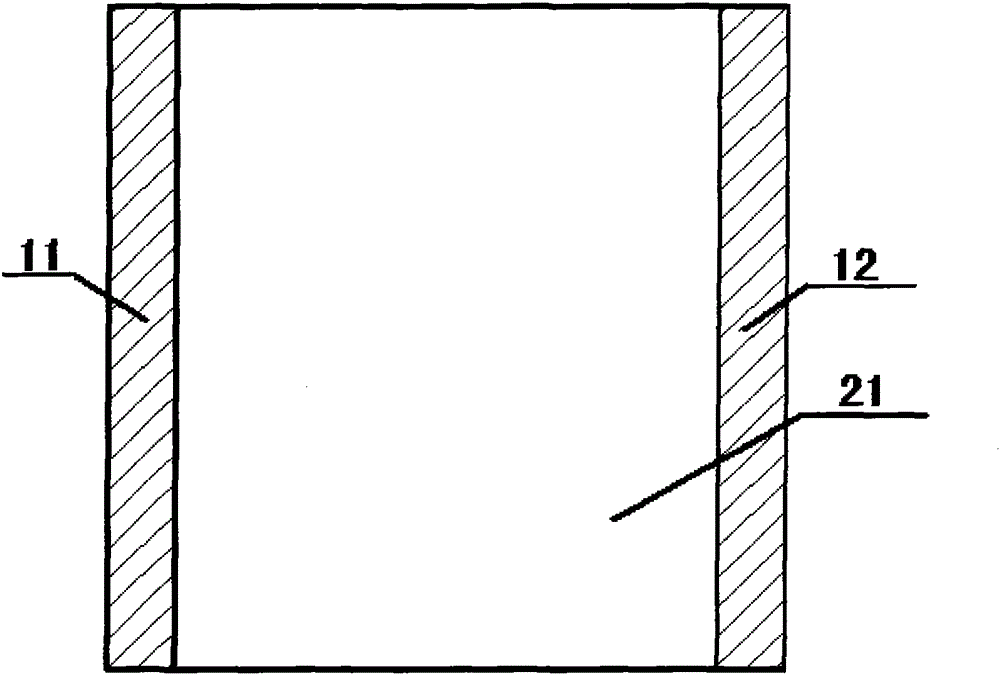

[0016] 1. If figure 1 As shown, a protective coal pillar 21 is left after strip coal pillar mining, and goafs 11 and 12 are located on both sides of the protective coal pillar respectively.

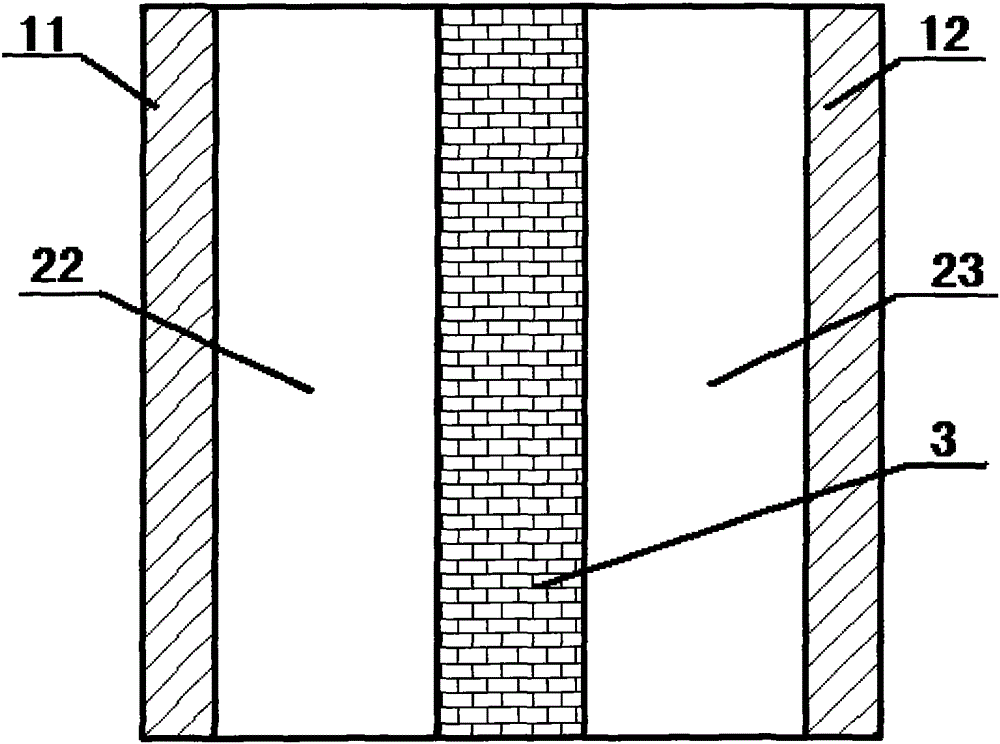

[0017] A small strip working face is arranged in the middle of the protective coal pillar 21 left after strip coal pillar mining for mining, and the reserved protective coal pillar 21 is partially recovered first;

[0018] 2. If figure 2 As shown, a small strip working face is mined in the middle of the reserved protective coal pillar 21, and the mined-out area after the mining of the small strip working face is filled with a filling body 3, and the remaining small strip coal pillars 22 and twenty three. The filling body is made of paste material, and then pushed back. In the advancing project of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com