Benzyl benzoate waste modified coal tar pitch and preparation method thereof

A technology of benzyl benzoate and coal tar pitch is applied in building components, building insulation materials, buildings and other directions, which can solve the problems of no treatment method and environmental pollution, and achieve the effects of being beneficial to environmental protection, reducing costs and maintaining performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

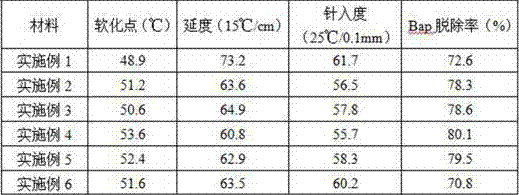

Examples

Embodiment 1

[0024] A kind of benzyl benzoate waste modified coal tar pitch, is characterized in that: this modified coal tar pitch is made of the raw material of following parts by weight: 100 parts of low-temperature coal tar pitch, 40 parts of benzyl benzoate waste, 30 parts of toluene, B 10 parts of diol, 3 parts of sodium dodecylbenzenesulfonate, 3 parts of 2,6-di-tert-butylcresol, and 3 parts of zinc stannate.

[0025] The preparation method of benzyl benzoate leftovers modified coal tar pitch comprises following processing steps:

[0026] (1) First put the coal tar pitch into the reaction kettle with reflux device, heat it to 60-110°C, then add toluene and ethylene glycol into the kettle, stir for 20-30min, and the stirring speed is 300-500r / min;

[0027] (2) Then add benzyl benzoate waste, sodium dodecylbenzenesulfonate, 2,6-di-tert-butylcresol and zinc stannate to the reaction kettle in sequence, stir for 1-2h, and the stirring speed is 300-500r / min , to obtain the modified coal ...

Embodiment 2

[0030] A kind of benzyl benzoate waste modified coal tar pitch is characterized in that: the modified coal tar pitch is made of the following raw materials in parts by weight: 50 parts of low-temperature coal tar pitch, 50 parts of medium temperature coal tar pitch, and 50 parts of benzyl benzoate waste , 30 parts of toluene, 12 parts of ethylene glycol, 5 parts of sodium dodecylbenzenesulfonate, 2 parts of 2,6-di-tert-butylcresol, and 3 parts of zinc stannate.

[0031] The preparation method of benzyl benzoate leftovers modified coal tar pitch comprises following processing steps:

[0032] (1) First put the coal tar pitch into the reaction kettle with reflux device, heat it to 60-110°C, then add toluene and ethylene glycol into the kettle, stir for 20-30min, and the stirring speed is 300-500r / min;

[0033] (2) Then add benzyl benzoate waste, sodium dodecylbenzenesulfonate, 2,6-di-tert-butylcresol and zinc stannate to the reaction kettle in sequence, stir for 1-2h, and the sti...

Embodiment 3

[0036] A kind of benzyl benzoate waste modified coal tar pitch, it is characterized in that: this modified coal tar pitch is made of the raw material of following parts by weight: 90 parts of medium temperature coal tar pitch, 60 parts of benzyl benzoate waste, 25 parts of toluene, B 15 parts of diol, 5 parts of sodium dodecylbenzenesulfonate, 2 parts of 2,6-di-tert-butylcresol, and 2 parts of zinc stannate.

[0037] The preparation method of benzyl benzoate leftovers modified coal tar pitch comprises following processing steps:

[0038] (1) First put the coal tar pitch into the reaction kettle with reflux device, heat it to 75-110°C, then add toluene and ethylene glycol into the kettle, stir for 20-30min, and the stirring speed is 300-500r / min;

[0039] (2) Then add benzyl benzoate waste, sodium dodecylbenzenesulfonate, 2,6-di-tert-butylcresol and zinc stannate to the reaction kettle in sequence, stir for 1-2h, and the stirring speed is 300-500r / min , to obtain the modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com