Long-acting anti-static coating and anti-static coating

An anti-static coating, long-term technology, applied in the field of material chemistry, can solve the problem that the anti-static and light-transmitting effects of anti-static coatings cannot meet the requirements of use at the same time, and achieve good anti-static effect, excellent adhesion performance, and anti-static effect lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

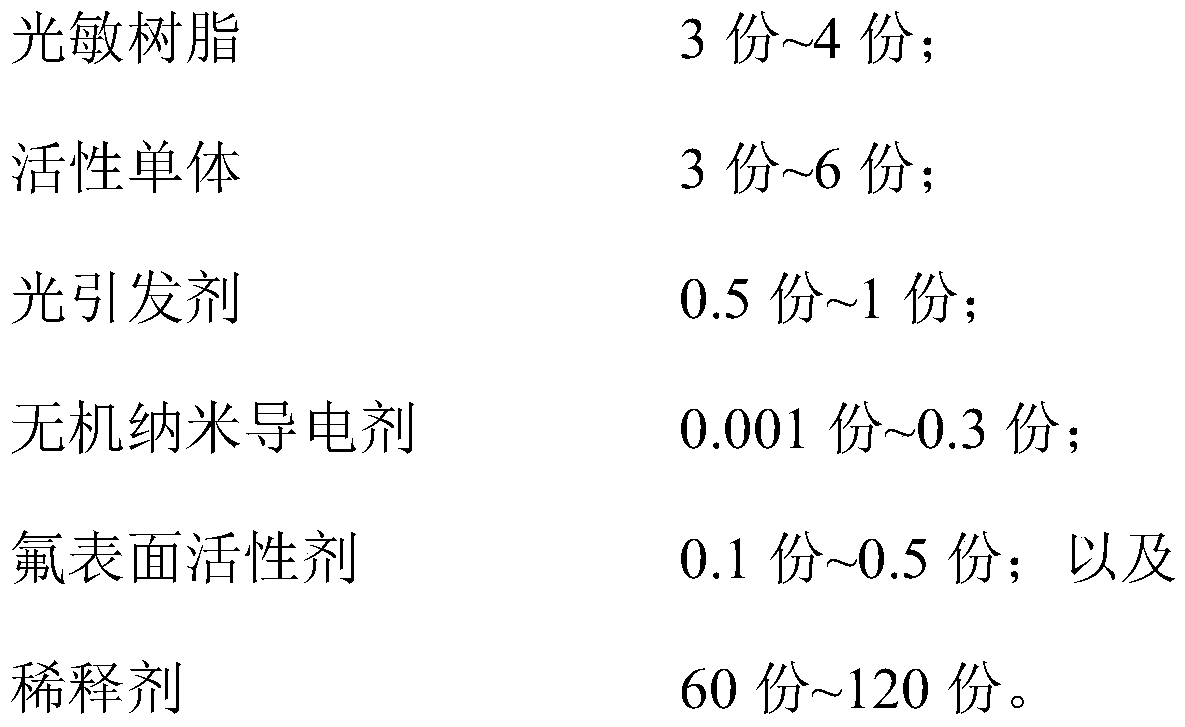

[0037] The preparation method of above-mentioned long-acting antistatic coating of the present invention comprises the steps:

[0038]The fluorosurfactant is firstly mixed and dispersed with the inorganic nano-conductive agent, and then mixed with the photosensitive resin, active monomer, photoinitiator, fluorosurfactant and diluent.

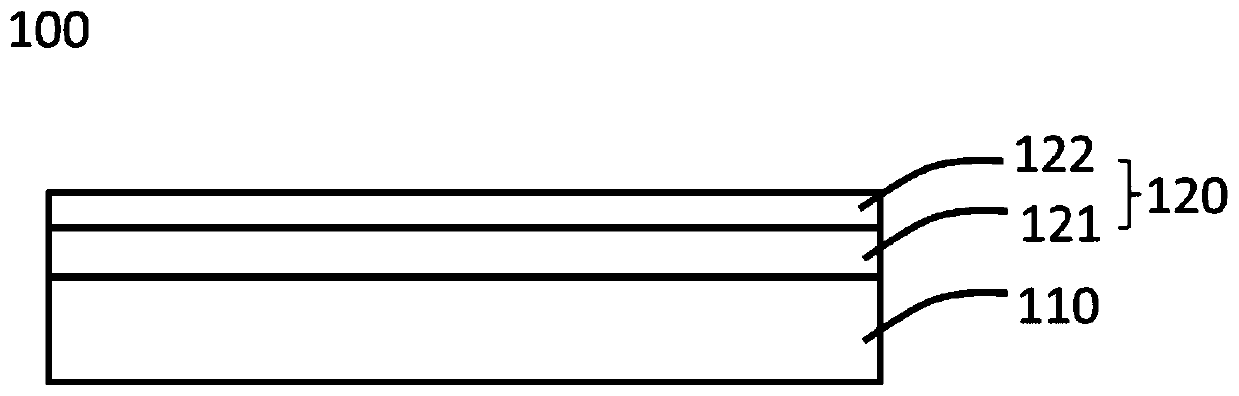

[0039] The invention provides an antistatic coating, and the material forming the antistatic coating includes the above-mentioned long-lasting antistatic coating.

[0040] The present invention also provides an antistatic product having the above-mentioned antistatic coating.

[0041] The antistatic coating is obtained by coating the above-mentioned long-lasting antistatic coating on the base material through a coating process, followed by drying and photocuring.

[0042] Further, the coating process can be spray coating, flow coating, dip coating, roller coating, brush coating and the like. The coating process is simple and easy to operate. ...

Embodiment 1

[0051] Mix and disperse 3kg of 6-functional urethane acrylate oligomer with 0.39kg of perfluoroalkyl ether carboxylate potassium salt, and then mix with 2kg of TMPTA, 2kg of TPGDA, 0.5kg of 1-hydroxy-cyclohexyl-phenyl ketone, and 11.8kg of water , 5 kg of ethanol, 35 kg of n-propanol, 30 kg of n-butanol, 10 kg of dimethylacetamide, 0.01 kg of carbon nanotubes and 0.3 kg of 2,6-di-tert-butyl-p-cresol and mix well to obtain a long-lasting antistatic coating.

Embodiment 2

[0053] Mix and disperse 3kg of 4-functional urethane acrylate oligomer with 0.39kg of sodium perfluorononenyloxybenzene sulfonate, then mix with DPHA 2kg, TPGDA 2kg, 1-hydroxy-cyclohexyl-phenyl ketone 0.5kg, water Mix 11.8kg, ethanol 5kg, n-propanol 35kg, n-butanol 30kg, dimethylacetamide 10kg, carbon nanotubes 0.01kg and 2,6-di-tert-butyl-p-cresol 0.3kg to obtain long-term antistatic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com