Bamboo cellulose aerogel thermal insulation material as well as preparation method and application thereof

The technology of cellulose aerogel and thermal insulation material is applied in the field of building thermal insulation materials, which can solve the problems of large environmental pollution of chemical reagents, complex preparation process, difficult promotion, etc., and achieves low price, simple preparation process and short preparation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

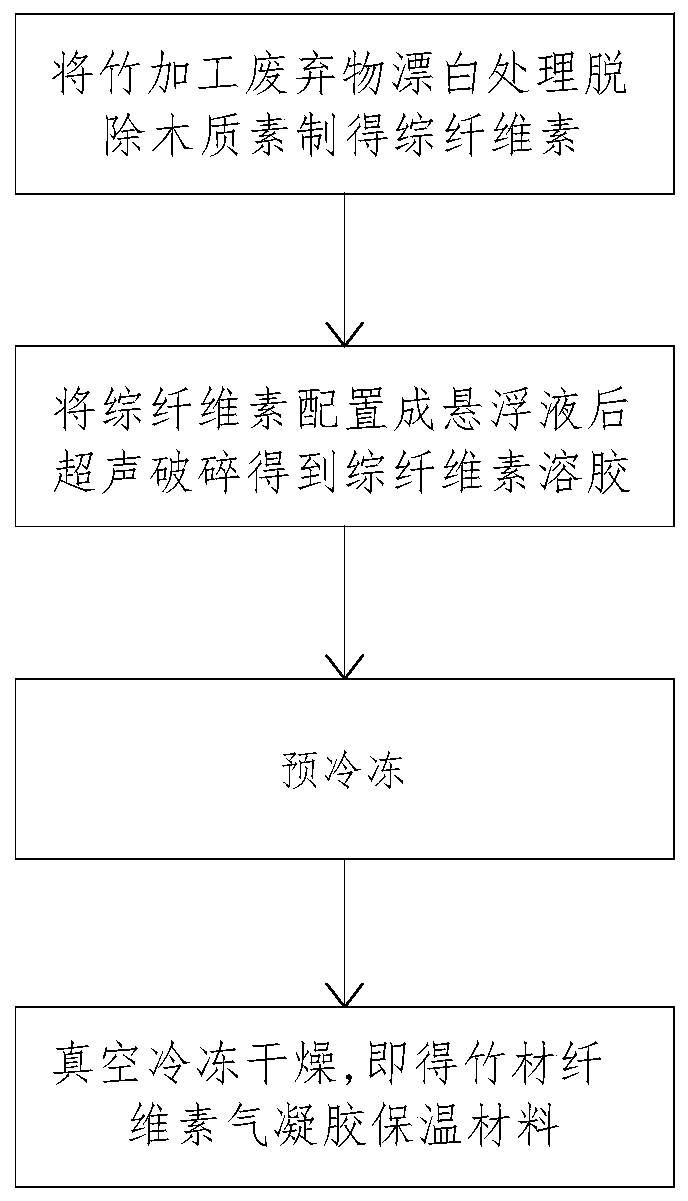

[0038] The embodiment of the present invention provides a kind of preparation method of bamboo cellulose airgel insulation material, such as figure 1 As shown, it specifically includes the following steps:

[0039] S1, get bamboo processing waste, put into container after washing with deionized water, add the 1.0wt% sodium chlorite solution that quality is 15 times of bamboo processing waste, meanwhile, add glacial acetic acid to adjust its pH value 4.0, and treated in a water bath at 75°C for 6 hours, wherein sodium chlorite and glacial acetic acid were added every hour, and the concentration and pH of the sodium chlorite solution were controlled to be 1.0 wt% and 4.0 , to remove lignin, and then wash to neutral with deionized water to obtain comprehensive cellulose;

[0040] S2, get 10g of the heald cellulose sample prepared in step S1 and add it to 990g deionized water, disperse to obtain a heald cellulose suspension with a concentration of 1wt%, then use the industrial ul...

Embodiment 2

[0045] The embodiment of the present invention provides a preparation method of bamboo cellulose airgel thermal insulation material, which is similar to embodiment 1 and specifically includes the following steps:

[0046] S1, get bamboo processing waste, put into container after washing with deionized water, add the 1.2wt% sodium chlorite solution that quality is 13.5 times of bamboo processing waste, meanwhile, add glacial acetic acid to adjust its pH value 3.5, and treated in a water bath at 75°C for 5 hours, wherein, every hour, sodium chlorite and glacial acetic acid were added to control the concentration and pH of the sodium chlorite solution to be 1.2wt% and 3.5% respectively , to remove lignin, and then wash to neutral with deionized water to obtain comprehensive cellulose;

[0047] S2, get 10g of the heald cellulose sample prepared in step S1 and add it to 990g deionized water, disperse to obtain a heald cellulose suspension with a concentration of 1wt%, then use the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com