Variable iridescent liquid crystal photonic crystal material and preparation method thereof

A technology of photonic crystals and iridescent colors, applied in liquid crystal materials, chemical instruments and methods, etc., can solve problems such as poor mechanical properties, difficulty in further expansion of three-dimensional dimensions, difficulty in photonic crystal materials, etc., and achieve good mechanical properties and easy three-dimensional dimensions Extend the effect of extension and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

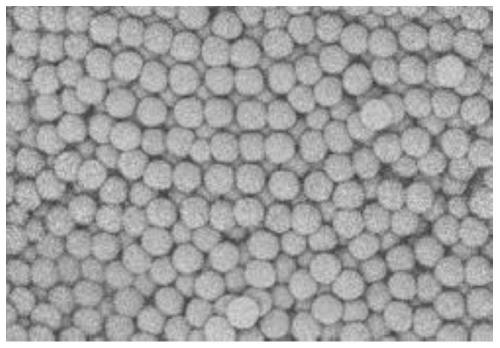

[0051] Embodiment 1: the preparation method of the liquid crystal photonic crystal material of variable iridescent color described in the present invention

[0052] (1) Mix 30ml of ethanol, 80ml of water and 0.1g of sodium lauryl sulfate, and heat up to 70°C;

[0053] (2) Mix 7g of styrene, 0.5g of divinylbenzene, 0.1g of RM-82 and 0.01g of photoinitiator 369, and stir for 10min;

[0054] (3) Add 4 g of the mixture obtained in step (2) to 65 ml of the mixture obtained in step (1);

[0055] (4) in the mixture that step (3) obtains, add potassium persulfate, wherein the addition of potassium persulfate and the ratio of the massfraction of styrene described in step (2) are 0.5%:100%; Then ultraviolet Light irradiation for 15 minutes, keeping at 70°C under nitrogen for 3h, and then freeze-drying at 1 mTorr and -30°C for 13h to obtain colloidal microsphere powder with a particle size of 10nm;

[0056] (5) The colloidal microsphere powder obtained in step (4) is subjected to a t...

Embodiment 2

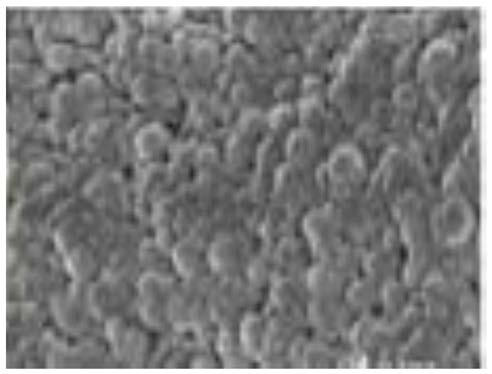

[0059] Embodiment 2: the preparation method of the iridescent liquid crystal photonic crystal material of the present invention

[0060] (1) Mix 70ml of ethanol, 120ml of water and 1g of hexadecane, and heat up to 90°C;

[0061] (2) Mix 9g of methyl methacrylate, 2g of ethylene glycol dimethacrylate, 2g of RM-257 and 3690.2g of photoinitiator, and stir for 20min;

[0062] (3) Add 6 g of the mixture obtained in step (2) to 85 ml of the mixture obtained in step (1);

[0063] (4) in the mixture that step (3) obtains, add potassium persulfate, wherein the ratio of the amount of potassium persulfate added and the massfraction of methyl methacrylate described in the step (2) is 1.5%: 100%; then irradiated with ultraviolet light for 30 minutes, kept at 100°C under nitrogen for 9h, and then freeze-dried at 100 mtorr and -30°C for 11 hours to obtain colloidal microsphere powder with a particle size of 360nm;

[0064] (5) The colloidal microsphere powder obtained in step (4) is subj...

Embodiment 3

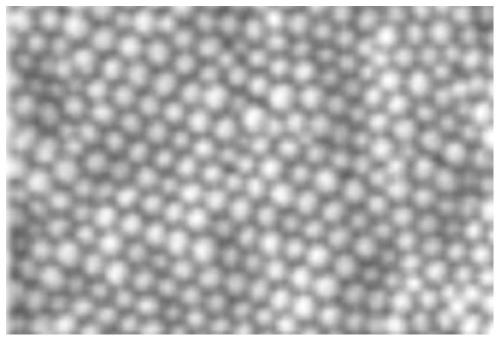

[0067] Embodiment 3: the preparation method of the liquid crystal photonic crystal material of variable iridescence described in the present invention

[0068] (1) Mix 50ml of ethanol, 100ml of water and 0.8g of polyvinyl alcohol, and heat up to 80°C;

[0069] (2) Mix ethyl methacrylate 9g, divinylbenzene 2g, R6M 2g and photoinitiator 365 0.2g, and stir for 15min;

[0070] (3) Add 5 g of the mixture obtained in step (2) to 75 ml of the mixture obtained in step (1);

[0071] (4) Add azobisisobutyronitrile to the mixture obtained in step (3), wherein the addition amount of said azobisisobutyronitrile and the mass fraction of ethyl methacrylate in said step (2) The ratio is 1%: 100%; then irradiated by ultraviolet light for 30min, kept at 70°C under nitrogen for 5h, then freeze-dried at 50 mTorr and at -30°C for 13h to obtain a colloidal microsphere powder with a particle size of 250nm;

[0072] (5) The colloidal microsphere powder obtained in step (4) is subjected to a therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com