Organic compound and preparation method and application thereof

An organic compound, unsubstituted technology, used in organic chemistry, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve problems such as recrystallization, low glass transition temperature of CBP, and reduced device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

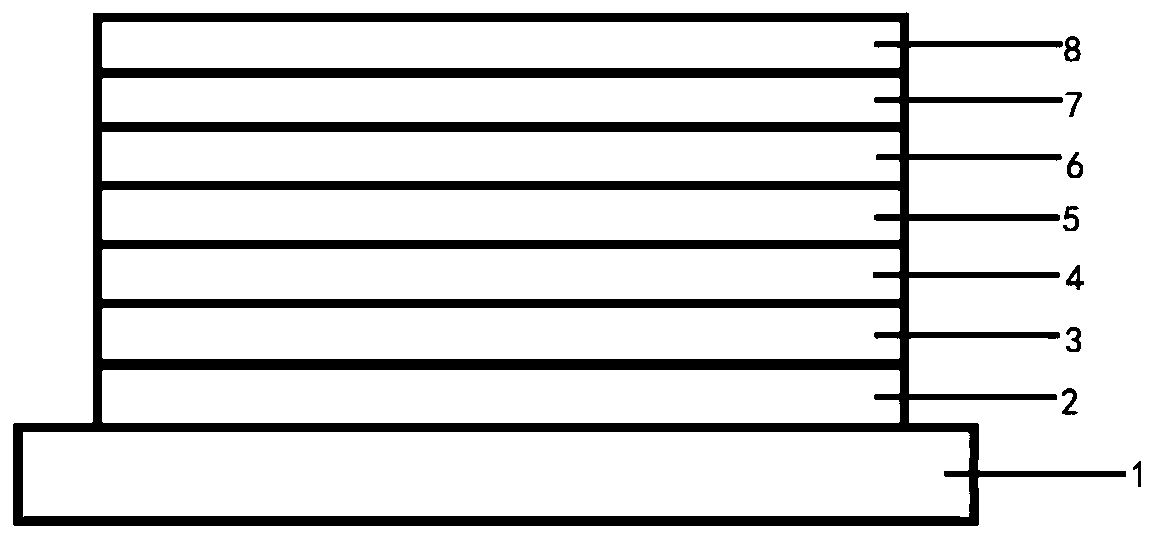

[0157]The preparation method of the organic electroluminescent device is as follows:

[0158] (1) Substrate cleaning: the transparent glass substrate coated with ITO is ultrasonically treated in an aqueous cleaning agent (composition and concentration of the aqueous cleaning agent: ethylene glycol solvent≤10wt%, triethanolamine≤1wt%), Rinse in deionized water, ultrasonically degrease in acetone:ethanol mixed solvent (volume ratio 1:1), bake in a clean environment until the water is completely removed, and then clean with ultraviolet light and ozone.

[0159] (2) Evaporation of organic light-emitting functional layer:

[0160] Place the above-mentioned glass substrate with an anode layer in a vacuum chamber and evacuate to 1×10 -6 to 2×10 -4 Pa, vacuum-evaporated HAT(CN) on the above-mentioned anode layer film 6 As a hole injection layer, the evaporation rate is 0.1nm / s, and the evaporation thickness is 10nm;

[0161] Evaporate the hole transport layer on the hole injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com