An inorganic grouting material capable of stopping water and reinforcing structures, its preparation method and application

A grouting material and reinforcement structure technology, applied in building insulation materials, building components, etc., can solve the problems of self-compactness influence, hard curing, weak bond strength, etc., achieve good compactness and corrosion resistance, improve resistance Permeability, good anti-wash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

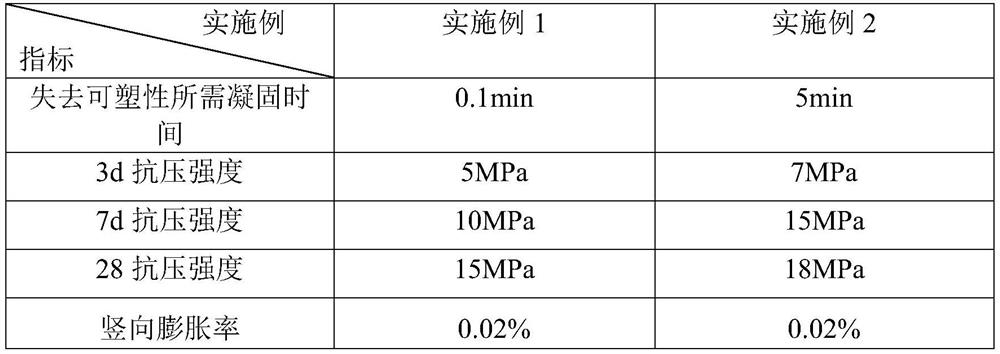

Embodiment 1

[0051] Inorganic grouting materials that can only be reinforced with water

[0052] A component (parts by weight): 4 parts of potassium silicate (30%), 3 parts of sodium silicate (40%), 1.5 parts of dispersant stearabamide, 4 parts of antifoam dimethyl silicone oil, water 10 share;

[0053] B component (parts by weight): 0.2 polycarboxylic acid high-efficiency water reducer, 20 high-performance ultrafine cement-based grouting materials, 8 parts of alkaline mineral powder, 0.5 silica gray, 3 fly ash, flocculant polymer 0.6 copper amides, 0.5 of the expansionizer magnesium oxide, and 10 water.

[0054] The inorganic grouting material of the present embodiment is faster, which can be a hole and gap that the water seepage is large.

Embodiment 2

[0056] Inorganic grouting materials that can only be reinforced with water

[0057] A component (parts by weight): 3 parts of potassium silicate (30%), 2 parts of sodium silicate (40%), 1 part of dispersant stearamide, 4.1 parts of antifoam dimethylsilicone oil, water 13 share;

[0058] B component (parts by weight): 0.2 parts of polycarboxylic acid, 25 parts of high performance ultra-fine cement-based grout, 9 parts of alkaline mineral powder, 0.7 silica gray, 2 fly ash, flocculant poly 0.6 copies of acrylamide, 0.5 of the expansionizer magnesium oxide, 1 order of cyclic citric acid, and 13 water.

[0059] The inorganic grout material of the present embodiment slows down the coagulation time compared to Example 1, which may be small and cracks with a small amount of water and high permeation requirements.

Embodiment 3

[0061] Inorganic grouting materials that can only be reinforced with water

[0062] A component (parts by weight): 3 parts of potassium silicate (30%), 2 parts of sodium silicate (40%), 1 dispersant stearidamide, 4.1 parts of antifoam dimethyl silicone oil, water 10 share;

[0063] B component (parts by weight): 20.1 parts of polycarboxylic acid, 20 parts of high-performance ultrafine cement-based grout, 8 parts of alkaline mineral powder, 0.5 silica, 2 parts, flocculant 0.5 copies of acrylamide, 0.5 of the expansion agent magnesium oxide, 1 hydrocolite citric acid, and 10 water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com