Inorganic grouting material capable of stopping open water and reinforcing structure as well as preparation method and application thereof

A grouting material and reinforcement structure technology, applied in building insulation materials, building components, etc., can solve the problems of self-compactness influence, hard curing, weak bond strength, etc., achieve good compactness and corrosion resistance, improve resistance Permeability, good anti-wash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

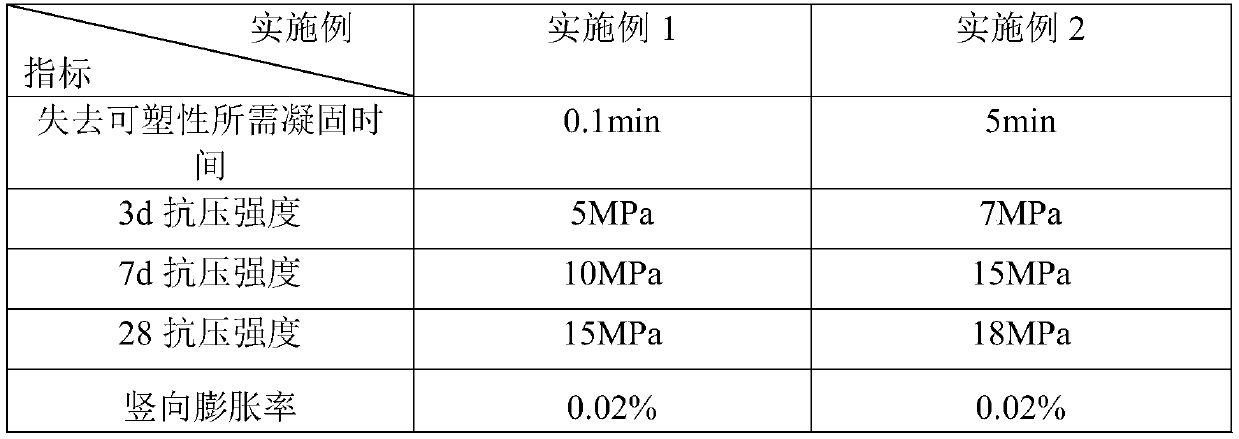

Embodiment 1

[0051] Inorganic grouting material that can prevent water and strengthen structures

[0052] Component A (parts by weight): 4 parts of potassium silicate aqueous solution (30%), 3 parts of sodium silicate aqueous solution (40%), 1.5 parts of dispersant stearamide, 0.2 part of antifoaming agent dimethyl silicone oil, 10 parts of water share;

[0053] Component B (parts by weight): 0.2 parts of polycarboxylate high-efficiency water reducer, 20 parts of high-performance superfine cement-based grouting material, 8 parts of alkaline mineral powder, 0.5 parts of silica fume, 3 parts of fly ash, flocculant poly 0.6 parts of acrylamide, 0.5 parts of expansion agent magnesium oxide, and 10 parts of water.

[0054] The inorganic grouting material of this embodiment has a fast solidification speed and can be used for cavities and gaps with large water seepage.

Embodiment 2

[0056] Inorganic grouting material that can prevent water and strengthen structures

[0057] Component A (parts by weight): 3 parts of potassium silicate aqueous solution (30%), 2 parts of sodium silicate aqueous solution (40%), 1 part of dispersant stearamide, 0.1 part of antifoaming agent dimethyl silicone oil, 13 parts of water share;

[0058] Component B (parts by weight): 0.2 parts of polycarboxylate high-efficiency water reducer, 25 parts of high-performance superfine cement-based grouting material, 9 parts of alkaline mineral powder, 0.7 parts of silica fume, 2 parts of fly ash, flocculant poly 0.6 parts of acrylamide, 0.5 parts of magnesium oxide as an expansion agent, 1 part of citric acid as a retarder, and 13 parts of water.

[0059] Compared with Example 1, the inorganic grouting material in this embodiment slows down the solidification time, and can target cavities and cracks with small water seepage and high penetration requirements.

Embodiment 3

[0061] Inorganic grouting material that can prevent water and strengthen structures

[0062] Component A (parts by weight): 3 parts of potassium silicate aqueous solution (30%), 2 parts of sodium silicate aqueous solution (40%), 1 part of dispersant stearamide, 0.1 part of antifoaming agent dimethyl silicone oil, 10 parts of water share;

[0063] Component B (parts by weight): 0.1 part of polycarboxylate high-efficiency water reducer, 20 parts of high-performance ultrafine cement-based grouting material, 8 parts of alkaline mineral powder, 0.5 part of silica fume, 2 parts of fly ash, flocculant poly 0.5 parts of acrylamide, 0.5 parts of magnesium oxide as an expansion agent, 1 part of citric acid as a retarder, and 10 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com