Method for accurately machining deep hole

A kind of machining and deep hole technology, applied in the field of mechanical processing of metal materials, can solve the problems of increasing processing procedures, poor lubrication, uneven force, etc., and achieve the effect of ensuring the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Present embodiment is the deep hole of 30mm * 717mm (aperture * hole depth) of 0.05mm processing parallelism on the TC4 titanium alloy cylindrical ingot of 400mm * 717mm (diameter * height), wherein, TC4 titanium alloy cylindrical ingot such as Figure 7 as shown, Figure 7 The middle TC4 titanium alloy cylindrical ingot has a blind hole 9 with a diameter of a=145mm and a hole depth of b=637mm, the distance from the bottom surface of the blind hole 9 on the TC4 titanium alloy cylindrical ingot to the bottom surface of the TC4 titanium alloy cylindrical ingot c = 80mm, and the diameter of the TC4 titanium alloy cylindrical ingot is d = 400mm.

[0041] This embodiment includes the following steps:

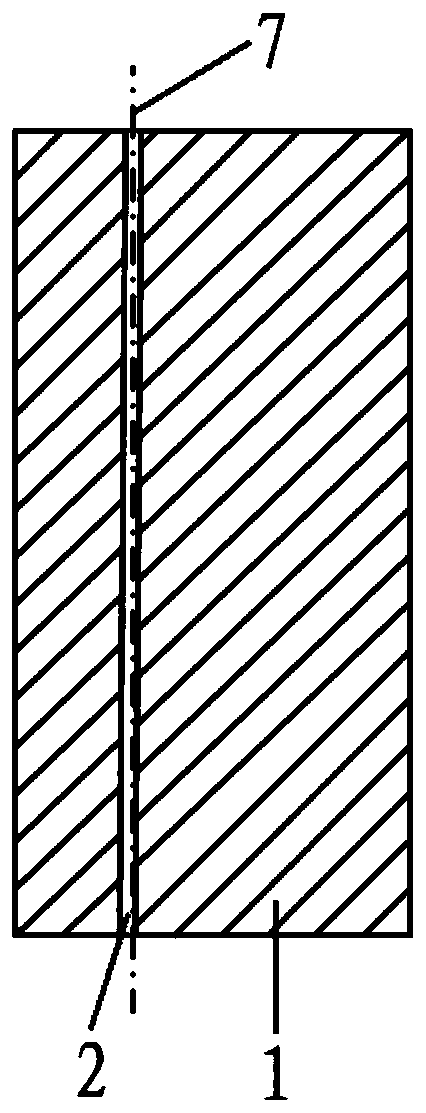

[0042] Step 1, the TC4 titanium alloy cylindrical ingot is drilled centered on the axis 7 of the designed deep hole on the TC4 titanium alloy cylindrical ingot to obtain a TC4 titanium alloy cylindrical ingot with a threading hole 2, such as Figure 8 Shown; The aperture of ...

Embodiment 2

[0068] This implementation is to process a deep hole of 24mm × 680mm (aperture × hole depth) with a parallelism of 0.1mm on a 304L stainless steel cube part with a side length of 680mm.

[0069] This embodiment includes the following steps:

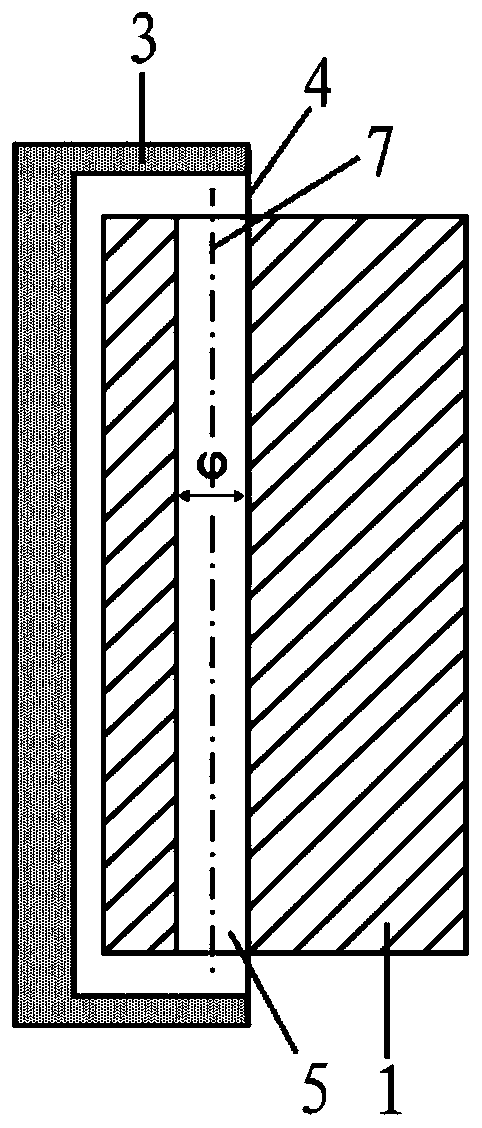

[0070] Step 1, the 304L stainless steel cube part is centered on the axis 7 of the design deep hole on the 304L stainless steel cube part to carry out the drilling process to obtain the 304L stainless steel cube part with the threading hole 2; the aperture of the threading hole 2 is 6mm ;

[0071] Step 2, first place the 304L stainless steel cube part with the threading hole 2 obtained in step 1 on the fixture of the wire electric discharge machine 3, and adjust the part with the threading hole 2 by adjusting the fixture of the wire electric discharge machine 3 The position of the 304L stainless steel cube part is until the three reference points are found on the axis 7 of the designed deep hole on the 304L stainless steel cube part with t...

Embodiment 3

[0077] This implementation is to process a deep hole of 35mm * 800mm (diameter * hole depth) with a parallelism of 0.1mm on a 6061 aluminum alloy cylindrical ingot of 500mm * 800mm (diameter * height).

[0078] This embodiment includes the following steps:

[0079] Step 1. Drilling the 6061 aluminum alloy cylindrical ingot centered on the axis 7 of the designed deep hole on the 6061 aluminum alloy cylindrical ingot to obtain a 6061 aluminum alloy cylindrical ingot with a threading hole 2; the threading The diameter of hole 2 is 7mm;

[0080] Step 2, first place the 6061 aluminum alloy cylindrical ingot with the threading hole 2 obtained in step 1 on the fixture of the wire electric discharge machine 3, and adjust the threading hole by adjusting the fixture of the wire electric discharge machine 3 2 The position of the 6061 aluminum alloy cylindrical ingot, until the three reference points are found on the axis 7 of the designed deep hole on the 6061 aluminum alloy cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com