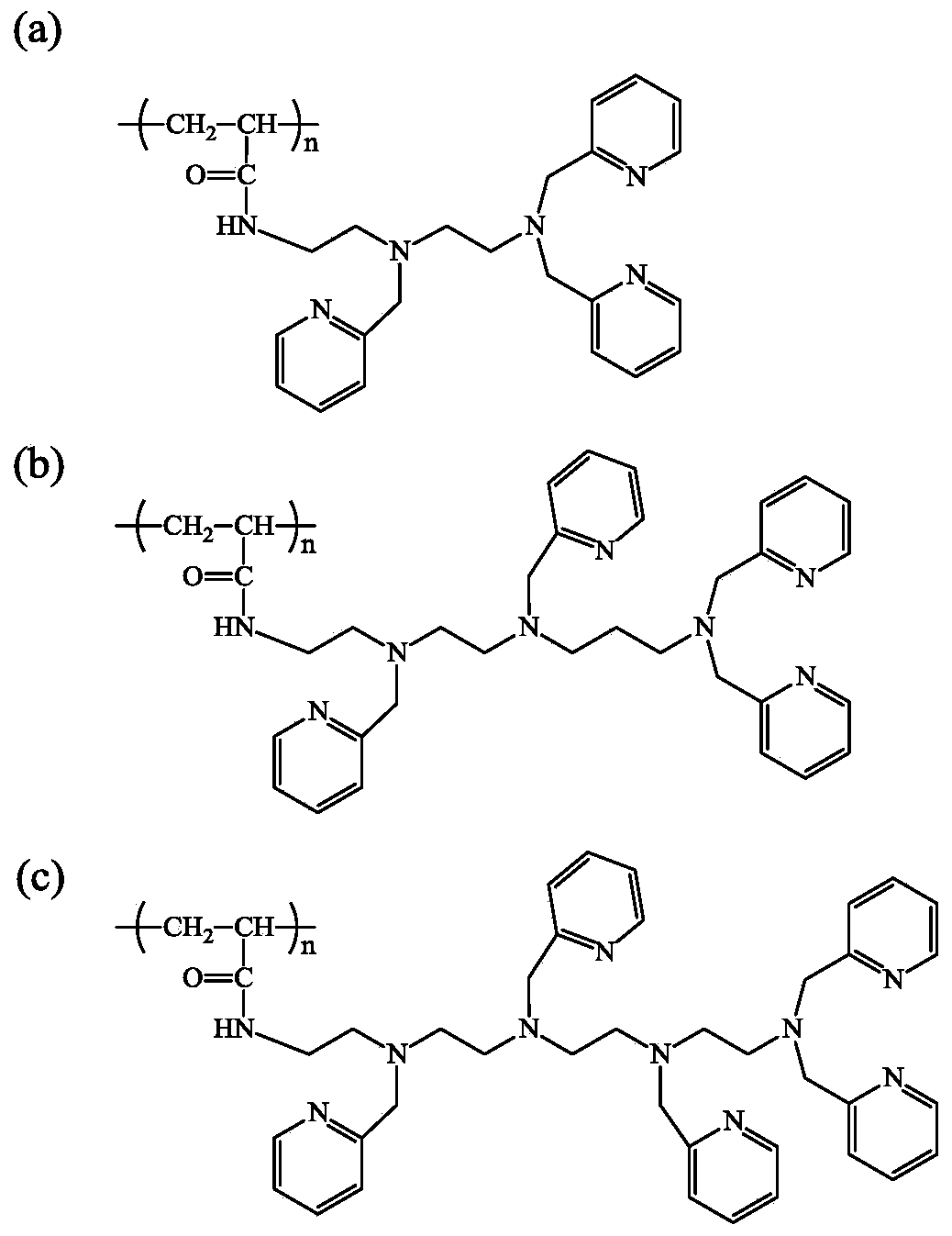

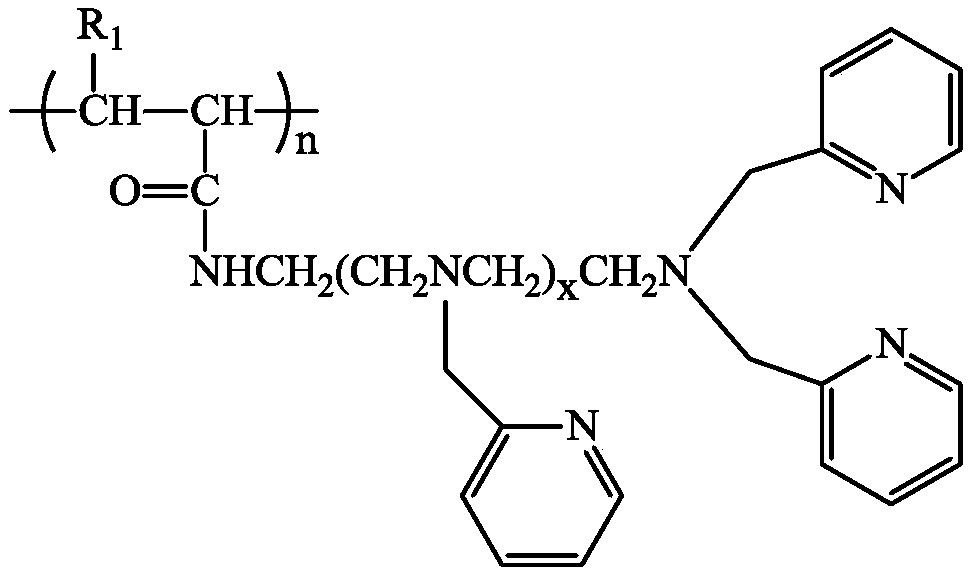

Pyridylamine chelate resin for removing heavy metal cations in strong acid wastewater and preparation method of pyridylamine chelate resin

A chelating resin, pyridine amine technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as the simultaneous removal of various heavy metal ions with reduced adsorption capacity, and achieve low cost and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: a kind of pyridine amine chelating resin and preparation method thereof for removing heavy metal cations in strongly acidic waste water, its steps are:

[0046] (a) Add 150mL of an aqueous solution containing 4wt% gelatin and 15wt% NaCl to a 500mL three-neck flask equipped with a stirrer and a reflux condenser, heat up to 40°C at a stirring speed of 80rpm, and keep for 1h;

[0047] (b) Add an oil phase composed of 25g methyl acrylate, 5g divinylbenzene, 55mL toluene and 2g azobisisobutyronitrile to the three-necked flask of step (a) at a stirring speed of 60rpm, adjust the stirring speed, and control the oil phase. The bead size range is 50-300 μm, then the temperature is raised to 60°C at a rate of 4°C / min, the temperature is raised to 75°C for 10 hours, the temperature is raised to 110°C for 10 hours, and the polymerization reaction is continued for 10 hours ℃, polymerization reaction 15h. The reaction product was extracted with ethanol through a Soxhle...

Embodiment 2

[0050] Embodiment 2: a kind of pyridine amine chelating resin and preparation method thereof for removing heavy metal cations in strongly acidic waste water, its steps are:

[0051] (a) Add 150mL of an aqueous solution containing 4wt% gelatin and 15wt% NaCl to a 500mL three-neck flask equipped with a stirrer and a reflux condenser, heat up to 40°C at a stirring speed of 80rpm, and keep for 1h;

[0052] (b) Add an oil phase composed of 25g methyl acrylate, 5g divinylbenzene, 55mL toluene and 2g azobisisobutyronitrile to the three-necked flask of step (a) at a stirring speed of 60rpm, adjust the stirring speed, and control the oil phase. The bead size range is 50-300 μm, then the temperature is raised to 60°C at a rate of 4°C / min, the temperature is raised to 75°C for 10 hours, the temperature is raised to 110°C for 10 hours, and the polymerization reaction is continued for 10 hours ℃, polymerization reaction 15h. The reaction product was extracted with ethanol through a Soxhle...

Embodiment 3

[0055] Embodiment 3: a kind of pyridine amine chelating resin and preparation method thereof for removing heavy metal cations in strongly acidic waste water, its steps are:

[0056] (a) Add 150mL of an aqueous solution containing 4wt% gelatin and 15wt% NaCl to a 500mL three-neck flask equipped with a stirrer and a reflux condenser, heat up to 40°C at a stirring speed of 80rpm, and keep for 1h;

[0057] (b) Add an oil phase composed of 25g methyl acrylate, 5g divinylbenzene, 55mL toluene and 2g azobisisobutyronitrile to the three-necked flask of step (a) at a stirring speed of 60rpm, adjust the stirring speed, and control the oil phase. The bead size range is 50-300 μm, then the temperature is raised to 60°C at a rate of 4°C / min, the temperature is raised to 75°C for 10 hours, the temperature is raised to 110°C for 10 hours, and the polymerization reaction is continued for 10 hours ℃, polymerization reaction 15h. The reaction product was extracted with ethanol through a Soxhle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com