Preparation method and application of bamboo-like magnetic nitrogen/metal cobalt doped carbon nanotube material

A technology of carbon nanotubes and metal cobalt, which is applied in the direction of carbon nanotubes, nanocarbons, alkali metal compounds, etc., can solve the problems of cumbersome, unfavorable large-scale production, and affecting applications, so as to improve dispersibility, facilitate separation and reuse , the effect of good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

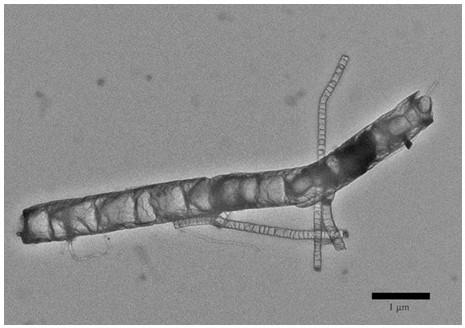

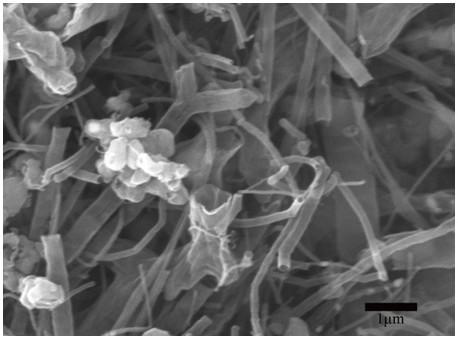

[0020] A preparation method of a bamboo-shaped magnetic nitrogen / metal cobalt doped carbon nanotube material, comprising the following steps:

[0021] 1) Mix 2.0 g melamine with 0.5 g CoCl 2 2H 2 O was mixed in a 30 mL crucible, added 2 mL of absolute ethanol and stirred to dissolve, and dried in a blast oven at 70 °C until the ethanol evaporated completely.

[0022] 2) Place the crucible in step 1) in a tube furnace, and continuously feed argon gas at a rate of 80 mL / min. After rising to 200 °C at a rate of 7 °C / min, keep for 2 h. Then it was raised to 1000°C at a rate of 7°C / min and calcined at 1000°C for two hours. Afterwards, the temperature was lowered to room temperature at a rate of 5°C / min, and the argon gas was turned off. A black solid will be obtained.

[0023] 3) The black solid obtained in step 2) was placed in a beaker filled with 1 mol / L hydrochloric acid and stirred at a speed of 180 r / min for 4 h, washed alternately with deionized water and absolute ethan...

Embodiment 2

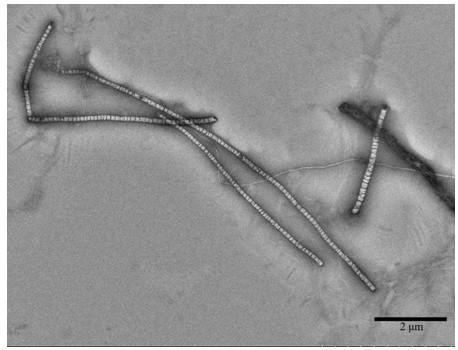

[0026] A preparation method of a bamboo-shaped magnetic nitrogen / metal cobalt doped carbon nanotube material, comprising the following steps:

[0027] 1) Mix 3.0 g urea with 0.5 g CoCl 2 2H 2 O was mixed in a 30 mL crucible, added 2 mL of absolute ethanol and stirred to dissolve, and dried in a blast oven at 70 °C until the ethanol evaporated completely.

[0028] 2) Place the crucible in step 1) in a tube furnace, and continuously feed argon gas at a rate of 80 mL / min. After rising to 200 °C at a rate of 7 °C / min, keep for 2 h. Then it was raised to 1000°C at a rate of 7°C / min and calcined at 1000°C for two hours. Afterwards, the temperature was lowered to room temperature at a rate of 5°C / min, and the argon gas was turned off. A black solid will be obtained.

[0029] 3) The black solid obtained in step 2) was placed in a beaker filled with 1 mol / L hydrochloric acid and stirred at a speed of 180 r / min for 4 h, washed alternately with deionized water and absolute ethanol t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com