Preparation method of heat-resistant stainless steel

A heat-resistant stainless steel, molten steel smelting technology, applied in the direction of reducing gas emissions, can solve the problems of surface quality, production stability and product service life gap, achieve excellent processability, achieve economic maximization effect, and ensure pickling quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

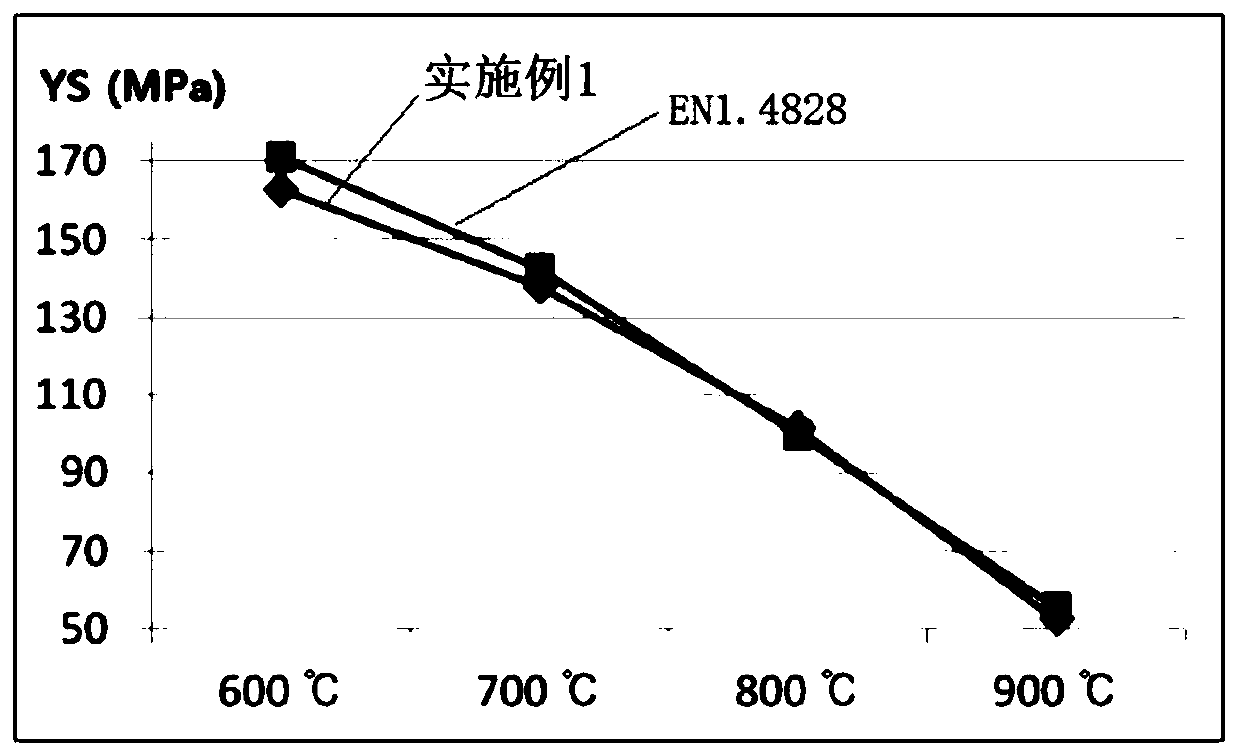

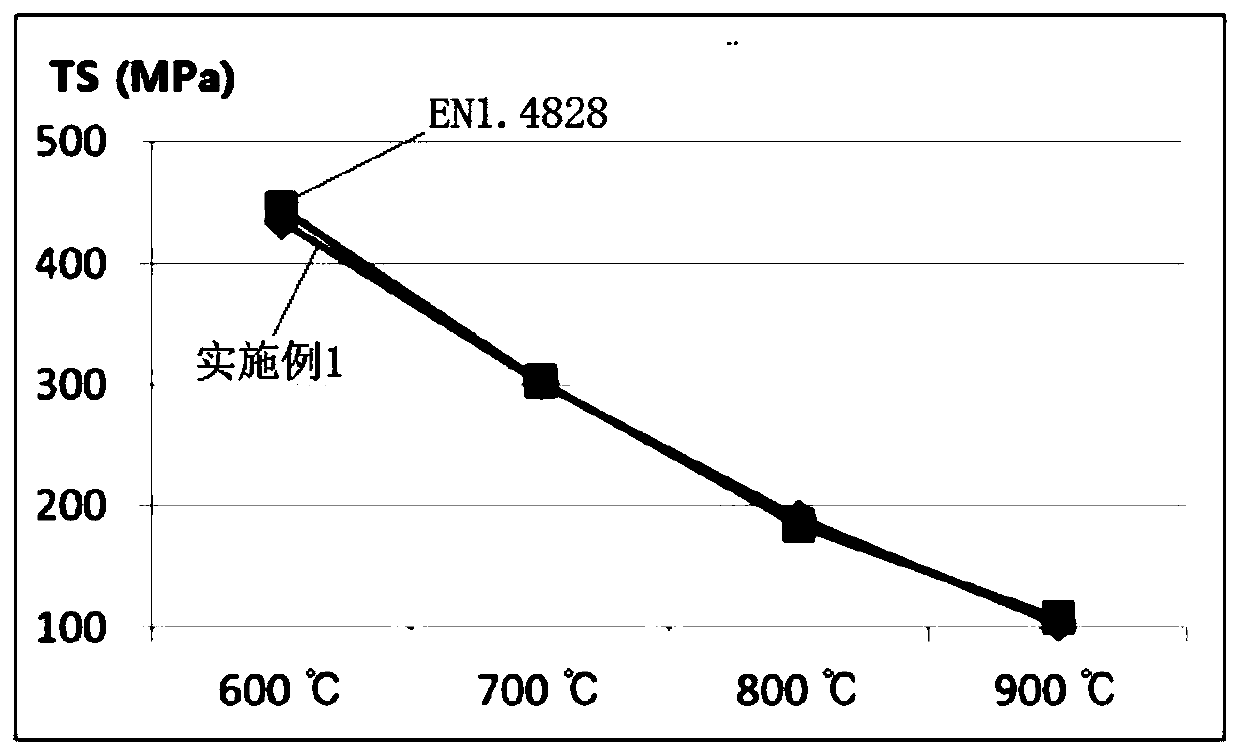

[0019] A method for preparing heat-resistant stainless steel, which is characterized by comprising the following steps: the raw materials of the heat-resistant stainless steel include: C: 0.04%, Si: 1.9%, Mn: 1.25%, P: ≤0.03% , S: ≤0.01%, Cr: 19.2%, Ni: 11.4%, N: 0.05%, the rest is Fe and unavoidable impurities; the service temperature of the heat-resistant stainless steel is ≤1000°C; the heat-resistant stainless steel Each raw material is subjected to molten steel smelting, annealing and pickling steps;

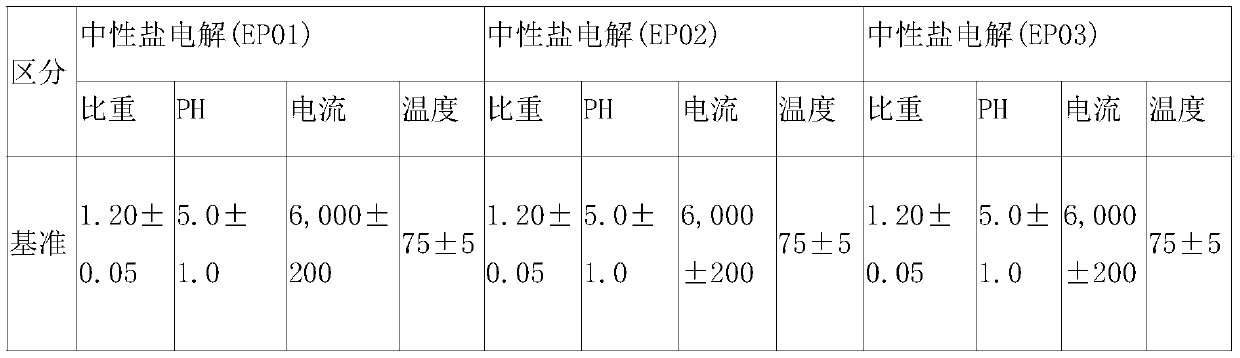

[0020] The molten steel smelting steps include: EAF electric furnace raw material input stage control, raw material ratio is STS + ordinary carbon steel + ChCr + pure NI, to ensure P≤0.025%; AOD argon oxygen decarburization refining; pre-desulfurization molten soup desulfurization process; continuous casting The process uses CaO-SiO 2 It is molten steel with low melting point steel slag; adopts Si+Al deoxidation technology; the refining process adopts complete slag removal ...

Embodiment 2

[0053] On the basis of the composition of the above heat-resistant stainless steel raw materials, the raw materials of heat-resistant stainless steel may also include: C: 0.02-0.06%, Si: 1.6-2.0%, Mn: 1.0-1.5%, P: ≤ 0.035%, S: ≤0.001%, Cr: 19.0-20.0%, Ni: 11.0-12.0%, N: ≤0.06%, and the rest are Fe and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com