High-strength hot galvanized steel sheet and preparation method thereof

A hot-dip galvanized steel sheet, high-strength technology, applied in the field of high-strength hot-dip galvanized steel sheet and its preparation, can solve the problems of poor elongation, high cost, poor mechanical properties of hot-dip galvanized steel sheet, etc., and achieve excellent surface quality , excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a method for preparing the above-mentioned high-strength hot-dip galvanized steel sheet, comprising the following steps:

[0026] The smelted molten steel is subjected to smelting-hot rolling-acid rolling-hot-dip galvanizing-annealing steps to obtain hot-dip galvanized steel sheets; the hot-rolling includes heating, dephosphorization, rough rolling, finish rolling, laminar cooling and coiling steps.

[0027] Among them, in the preparation method of the above-mentioned high-strength hot-dip galvanized steel sheet, in order to prevent warping defects in the hot rolling process and ensure the high-temperature coiling temperature at the same time, the starting temperature of the finish rolling in the hot rolling is 1100-1250 ° C, and the finishing rolling The temperature is 890-960°C.

[0028] Wherein, in the preparation method of the above-mentioned high-strength hot-dip galvanized steel sheet, in order to obtain a suitable ferrite and p...

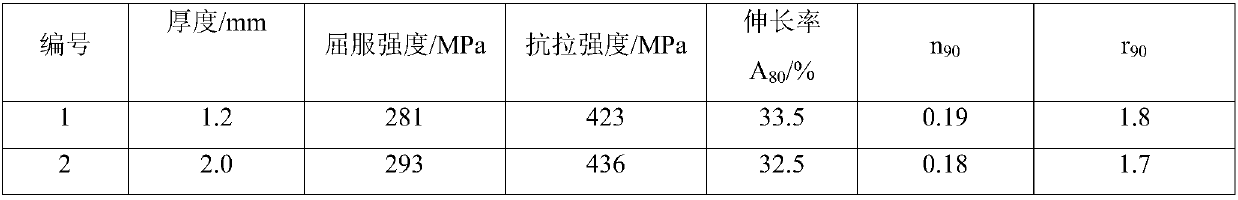

Embodiment 1-2

[0033] Embodiment 1-2 prepares hot-dip galvanized steel sheet with the inventive method

[0034] The specific operation steps are as follows:

[0035] (1) through common smelting process, prepared the baking hardening steel slab of chemical composition as shown in table 1 below:

[0036] Table 1 Chemical composition of high-strength hot-dip galvanized steel sheet (wt.%)

[0037] Numbering

C

Si

mn

P

S

als

Nb

Ti

B

1

0.0021

0.10

0.70

0.065

0.005

0.032

0.031

0.040

0.0008

2

0.0034

0.13

0.92

0.081

0.008

0.049

0.045

0.053

0.0010

[0038] (2) After the above-mentioned slab is heated, dephosphorized, hot-rolled and laminar-flow cooled, a hot-rolled coil is obtained, wherein each parameter is set as shown in Table 2 below:

[0039] Table 2 Main process parameters of hot rolling

[0040] Numbering

Finishing temperature / ℃

Finishing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com