A manufacturing process of hot work die steel for high-performance die-casting die

A hot-working die steel and manufacturing process technology, applied in the field of die steel, can solve the problems of poor surface hardness and core hardness, complex and cumbersome heat treatment process, and high production cost, so as to improve strength and toughness, prevent intragranular segregation, The effect of reducing the amount of austenite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

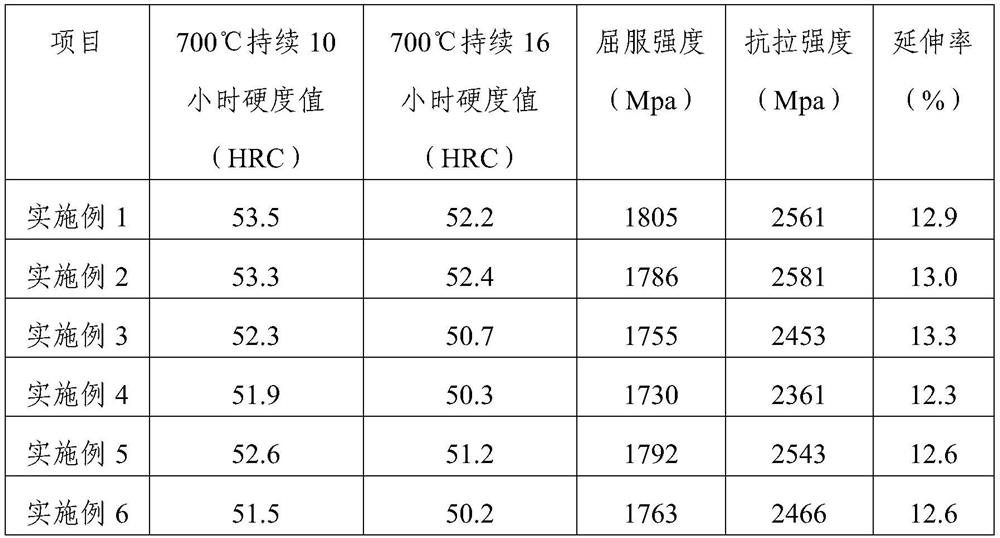

Examples

Embodiment 1

[0033] A hot work die steel for a die-casting mold, which consists of the following components by weight percentage:

[0034] C: 0.36%, Si: 2.2%, Mn: 0.35%, Mo: 2.1%, W: 3%, Nb: 0.19%, Cr: 3.6%, Sr: 0.29%, Ti: 0.22%, Ce: 0.06%, S≤0.003%, P≤0.03%, and the balance is Fe.

[0035] A manufacturing process for hot work die steel for high-performance die-casting molds, comprising the following steps:

[0036] (1) Smelting: batching is carried out according to the composition ratio of hot work die steel, smelted in a vacuum induction furnace, and cast to obtain a steel ingot, wherein the melting temperature is 1580°C, and the pouring temperature is 1480°C; then the steel ingot is electroslag remelted to obtain Electroslag steel ingot;

[0037] (2) High-temperature homogenization treatment: heat the electroslag steel ingot obtained in step (1) to 1270°C, keep it warm for 9 hours, and then air-cool to room temperature;

[0038] (3) Forging: Multi-directional forging is carried out o...

Embodiment 2

[0044] A hot work die steel for a die-casting mold, which consists of the following components by weight percentage:

[0045] C: 0.42%, Si: 1.8%, Mn: 0.4%, Mo: 1.8%, W: 3.5%, Nb: 0.23%, Cr: 2.8-3.7%, Sr: 0.46%, Ti: 0.28%, Ce: 0.09 %, S≤0.003%, P≤0.03%, and the balance is Fe.

[0046] A manufacturing process for hot work die steel for high-performance die-casting molds, comprising the following steps:

[0047] (1) Smelting: batching is carried out according to the composition ratio of hot work die steel, and the steel ingot is melted by vacuum induction furnace, and the melting temperature is 1610°C, and the pouring temperature is 1470°C; the steel ingot is then electroslag remelted to obtain Electroslag steel ingot;

[0048] (2) High-temperature homogenization treatment: heat the electroslag steel ingot obtained in step (1) to 1270°C, keep it warm for 10 hours, and then air-cool to room temperature;

[0049] (3) Forging: Multi-directional forging is carried out on the steel...

Embodiment 3

[0055] A hot work die steel for die-casting molds, consisting of the following components in weight percentage: C: 0.46%, Si: 1.8%, Mn: 0.35%, Mo: 2.3%, W: 2.6%, Nb: 0.16%, Cr: 3.2%, Sr: 0.21%, Ti: 0.31%, Ce: 0.07%, S≤0.003%, P≤0.03%, and the balance is Fe.

[0056] A manufacturing process for hot work die steel for high-performance die-casting molds, comprising the following steps:

[0057] (1) Smelting: batching is carried out according to the composition ratio of the hot work die steel, and the steel ingot is melted by vacuum induction furnace, and the melting temperature is 1610°C, and the pouring temperature is 1480°C; Electroslag steel ingot;

[0058] (2) High-temperature homogenization treatment: heat the electroslag steel ingot obtained in step (1) to 1290°C, keep it warm for 8 hours, and then air-cool to room temperature;

[0059] (3) Forging: Multi-directional forging is carried out on the steel ingot obtained through step (2). The starting forging temperature is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com