Titanium-containing cobalt-chromium alloy, preparation method and application thereof

A cobalt-chromium alloy and alloy technology, applied in the field of alloys, can solve the problems of inability to take into account biocompatibility, corrosion resistance, hardness, and metal-ceramic bonding strength, and achieve good alloy biocompatibility, improved matching, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

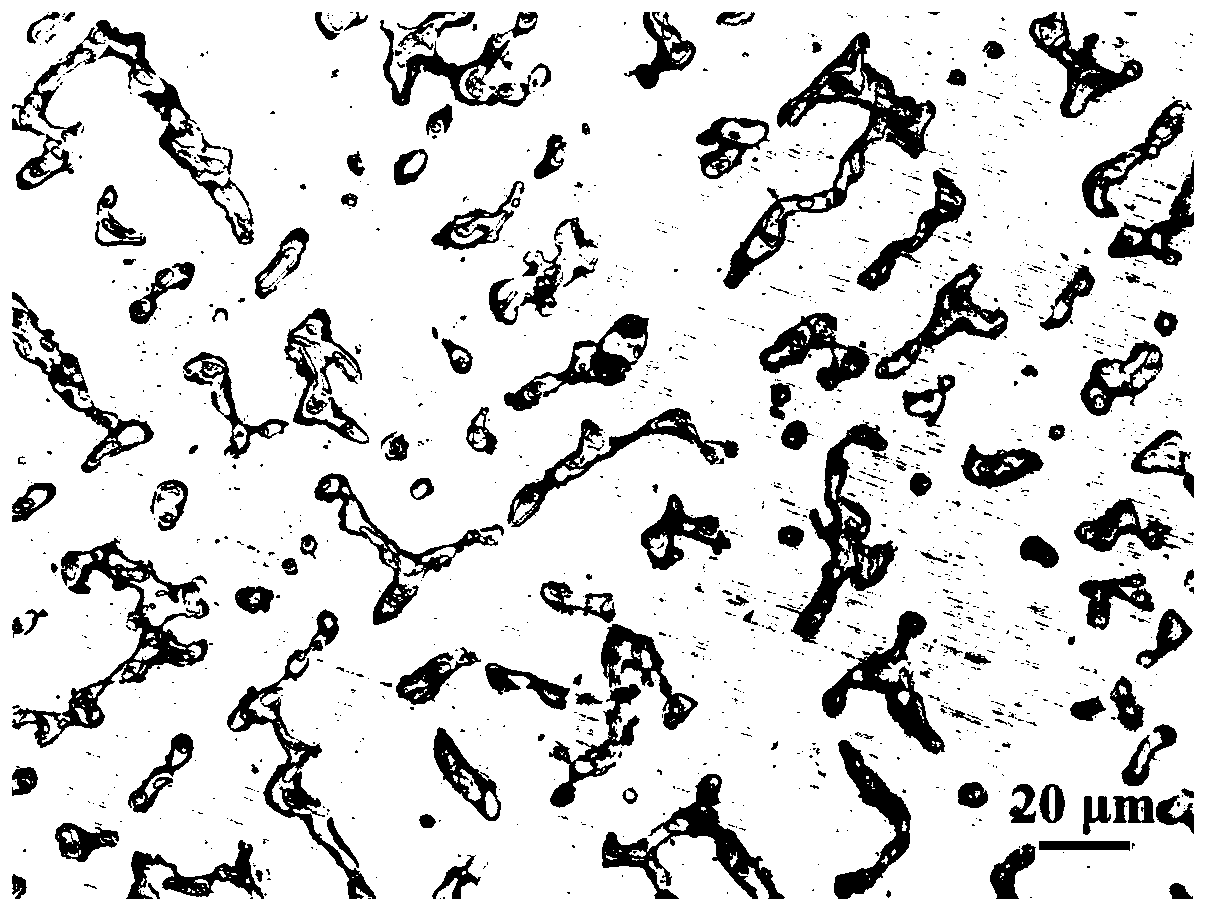

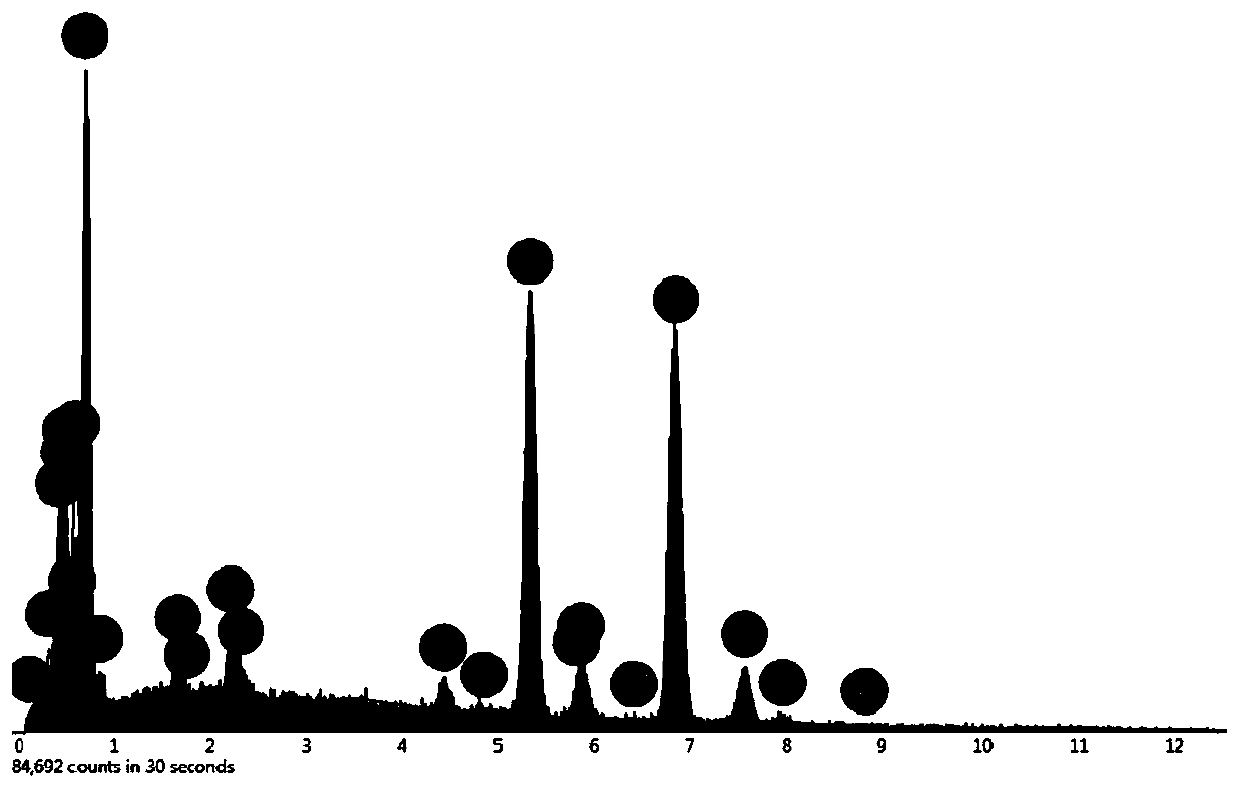

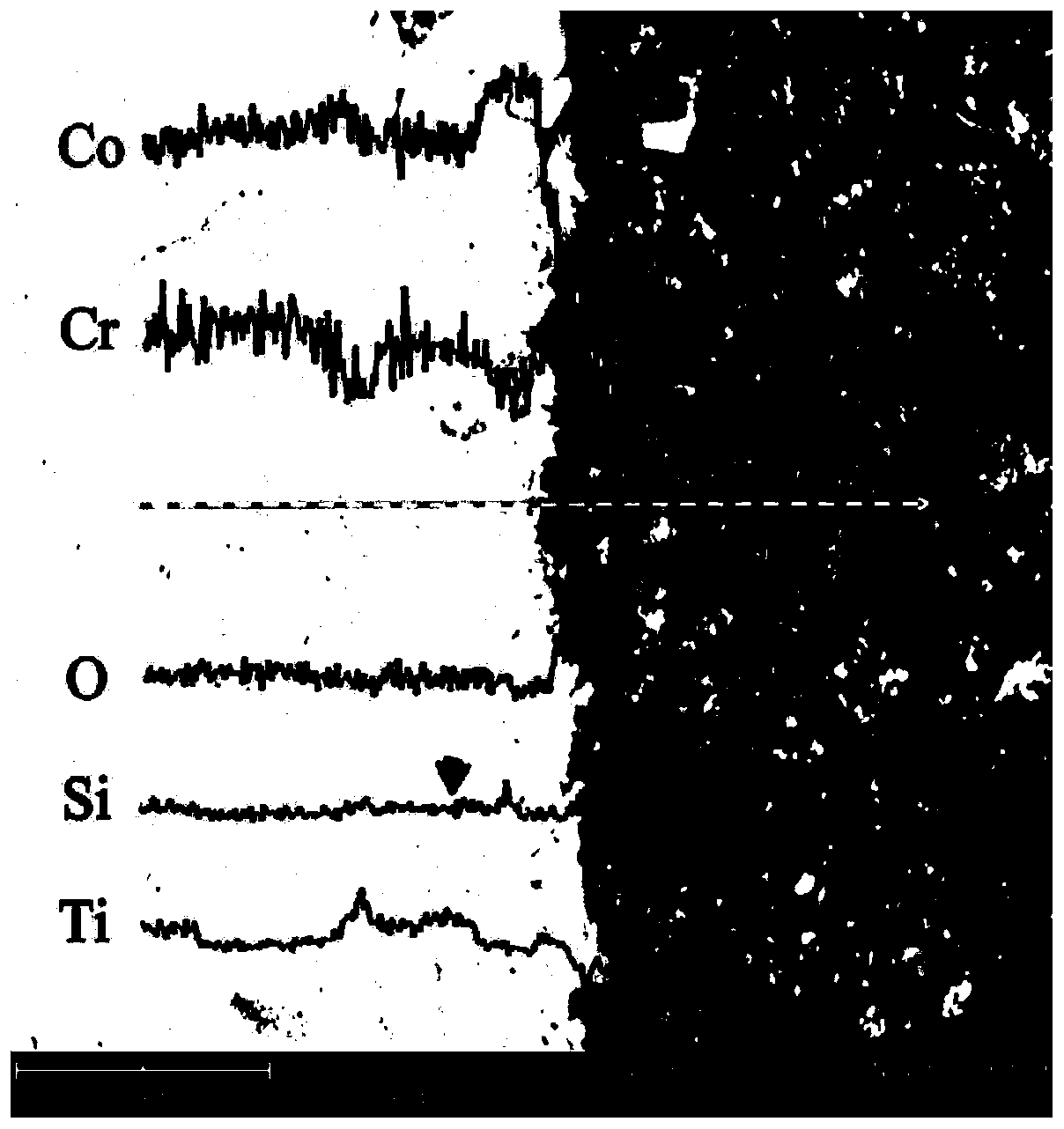

Image

Examples

Embodiment 1

[0049] This embodiment provides a titanium-containing cobalt-chromium alloy, which contains by weight percentage: 27.0% Cr, 6.0% Mo, 3.0% Ti, 2.5% Cu, 0.5% Mn, 0.7% Si, and the rest is Co .

[0050] The preparation method of the titanium-containing cobalt-chromium alloy of the present embodiment may further comprise the steps:

[0051] (1) Using metal chromium, metal molybdenum, metal titanium, electrolytic manganese, crystalline silicon, metal copper, and electrolytic cobalt as raw materials, according to Cr 27.0%, Mo 6.0%, Ti 3.0%, Cu 2.5%, Mn 0.5%, Si 0.7 %, the rest are the weight percent ingredients of Co, mixed uniformly;

[0052](2) Put the raw materials prepared in step (1) in a vacuum induction furnace, raise the temperature to 1450° C., and keep the temperature for 30 minutes.

Embodiment 2

[0054] This embodiment provides a titanium-containing cobalt-chromium alloy, which contains by weight percentage: 23.0% Cr, 8.0% Mo, 3.5% Ti, 4.0% Cu, 0.5% Mn, 0.5% Si, and the rest is Co .

[0055] The preparation method of the titanium-containing cobalt-chromium alloy of the present embodiment may further comprise the steps:

[0056] (1) Using metal chromium, metal molybdenum, metal titanium, electrolytic manganese, crystalline silicon, metal copper, and electrolytic cobalt as raw materials, according to Cr 23.0%, Mo 8.0%, Ti 3.5%, Cu 4.0%, Mn 0.5%, Si 0.5 %, the rest are the weight percent ingredients of Co, mixed uniformly;

[0057] (2) Put the raw materials prepared in step (1) in a vacuum induction furnace, raise the temperature to 1450° C., and keep the temperature for 30 minutes.

Embodiment 3

[0059] This embodiment provides a titanium-containing cobalt-chromium alloy, which contains by weight percentage: 30.0% Cr, 5.0% Mo, 1.5% Ti, 2.0% Cu, 0.5% Mn, 1.2% Si, and the rest is Co .

[0060] The preparation method of the titanium-containing cobalt-chromium alloy of the present embodiment may further comprise the steps:

[0061] (1) Using metal chromium, metal molybdenum, metal titanium, electrolytic manganese, crystalline silicon, metal copper, and electrolytic cobalt as raw materials, according to Cr 30.0%, Mo 5.0%, Ti 1.5%, Cu 2.0%, Mn 0.5%, Si 1.2 %, the rest are the weight percent ingredients of Co, mixed uniformly;

[0062] (2) Put the raw materials prepared in step (1) in a vacuum induction furnace, raise the temperature to 1450° C., and keep the temperature for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com