Method for producing neutral phytase through immobilized bacillus fermentation

A technology of bacillus and phytase, applied in the direction of microorganism-based methods, immobilized on or in inorganic carriers, biochemical equipment and methods, etc., can solve the problems of low enzyme production efficiency, low equipment utilization, and production costs Advanced problems, to achieve the effect of improving fermentation efficiency, improving utilization rate, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 The selection of inorganic carrier

[0040] (1) Seed liquid preparation: Streak inoculation of the Bacillus megaterium strain on LB slant medium, culture at a constant temperature of 37°C for 36~48h, then inoculate in the seed medium, under the conditions of temperature 37°C and rotation speed 180r / min Under culture to the logarithmic growth phase; the composition of the seed medium is: 15g / L glucose, 15g / L peptone, 4g / L yeast extract, 5g / L sodium chloride, 2g / L calcium chloride, 0.4g / L Magnesium sulfate, 0.2g / L potassium dihydrogen phosphate, 0.03g / L ferrous sulfate, pH7.0.

[0041] (2) Pretreatment of the carrier: choose fly ash, activated carbon, zeolite and ceramsite with a diameter of 2~3mm as the carrier, wash with distilled water and dry at 105°C for 2 hours; put the ceramsite into 1.0mol / L sodium hydroxide solution In this method, the material-liquid ratio of ceramsite and sodium hydroxide solution is 1g:5mL, shake and adsorb at 150r / min for 30min,...

Embodiment 2

[0047] According to the method in Example 1, the alkali-modified ceramsite was selected as the carrier to prepare immobilized cells, and then the continuous fermentation culture was carried out according to the following steps:

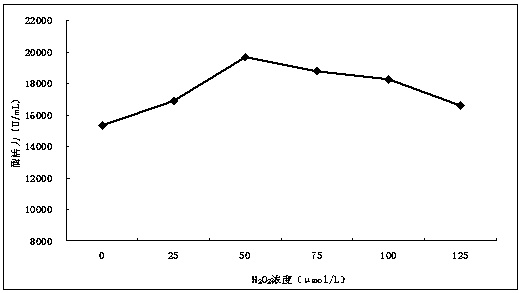

[0048] (1) Pre-cultivation: Add the fermentation medium into the fixed-bed reactor, and carry out circulating flow culture at a flow rate of 1.5L / h. The culture time is 36h, the temperature is 37°C, and the ventilation rate is 1.8vvm, and then released into the reactor culture medium; the composition of the fermentation medium is: 35g / L bran, 5g / L glucose, 15g / L bean cake powder, 7g / L ammonium sulfate, 2.5g / L sodium phytate, 6g / L sodium chloride, 2g / L calcium chloride, 0.15g / L potassium dihydrogen phosphate, 0.3g / L magnesium sulfate, 0.03g / L ferrous sulfate, 50μmol / L H 2 o 2 , 7.5g / L n-dodecane, pH7.0.

[0049] (2) Continuous fermentation culture: add fresh fermentation medium to 0.06h -1 The dilution ratio flows into a fixed-bed reactor for conti...

Embodiment 3

[0063] A kind of method that immobilized bacillus fermentation produces neutral phytase comprises the steps:

[0064] (1) Seed liquid preparation: Streak inoculation of the Bacillus megaterium strain on LB slant medium, culture at a constant temperature of 37°C for 36~48h, then inoculate in the seed medium, under the conditions of temperature 37°C and rotation speed 180r / min Under culture to the logarithmic growth phase; the composition of the seed medium is: 15g / L glucose, 15g / L peptone, 4g / L yeast extract, 5g / L sodium chloride, 2g / L calcium chloride, 0.4g / L Magnesium sulfate, 0.2g / L potassium dihydrogen phosphate, 0.03g / L ferrous sulfate, pH7.0.

[0065] (2) Pretreatment of the carrier: put ceramsite with a diameter of 2~3mm into 1.0mol / L sodium hydroxide solution, the ratio of solid to liquid between ceramsite and sodium hydroxide solution is 1g:5mL, shake at 150r / min Adsorb for 30 minutes, then let it stand for 24 hours, rinse the carrier with distilled water until the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com