Controllably removed strong adhesion type hydrogel and preparation method thereof

A hydrogel and adhesive technology, which is applied in the field of preparation of strong adhesive multifunctional hydrogel, can solve the problems of shortening the recovery time, hindering the integration of gel materials and the surface of biological tissues, etc., to achieve enhanced adhesion Force and cohesion, good biocompatibility and biodegradability, good wet adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

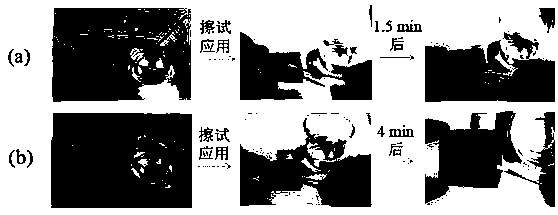

Image

Examples

example example 1

[0016] Gelatin was dissolved in PBS solution at 50°C to make a 10% w / v homogeneous solution. Then add 100 mg dopamine per gram of gelatin to the gelatin solution and stir evenly, then add 6 mg of genipin per gram of gelatin to the mixed solution at a rate of 0.5 mL / min, and keep stirring. The mixture was reacted at 37 °C for 6 h. Dialyze the gelatin solution against deionized water for 3 days using an 8-14 kDa cut-off dialysis bag to remove unreacted dopamine, genipin and any by-products. Freeze-dried for later use. The second network-hyaluronic acid was prepared by a two-step method. First, hyaluronic acid (1 g) and succinic anhydride (180 mg) were reacted in distilled water (100 mL) for 24 h to prepare hyaluronic acid succinate, which was dialyzed against deionized water for 3 hours using a 2 kDa cut-off dialysis bag. sky. N-Hydroxysuccinimide (200 mg) was then dissolved in distilled water (100 mL). The system was stirred at 37 °C for 24 h, and dialyzed against deionize...

example example 2

[0018] Gelatin was dissolved in PBS solution at 50°C to make a 10% w / v homogeneous solution. Then, 200 mg of dopamine per gram of gelatin was added to the gelatin solution and stirred evenly, and then 12 mg of genipin per gram of gelatin was added to the mixed solution at a rate of 0.5 mL / min, and the stirring was continued. The mixture was reacted at 50 °C for 12 h. Dialyze the gelatin solution against deionized water for 3 days using an 8-14 kDa cut-off dialysis bag to remove unreacted dopamine, genipin and any by-products. Freeze-dried for later use. The second network-hyaluronic acid was prepared by a two-step method. First, hyaluronic acid succinic acid was prepared by reacting hyaluronic acid (1 g) and succinic anhydride (180 mg) in distilled water (100 mL) for 24 h, and dialyzed against deionized water for 3 days using a 2 kDa cut-off dialysis bag . N-Hydroxysuccinimide (436 mg) was then dissolved in distilled water (100 mL). The system was stirred at 37 °C for 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com