Solidification method of radioactive waste residues

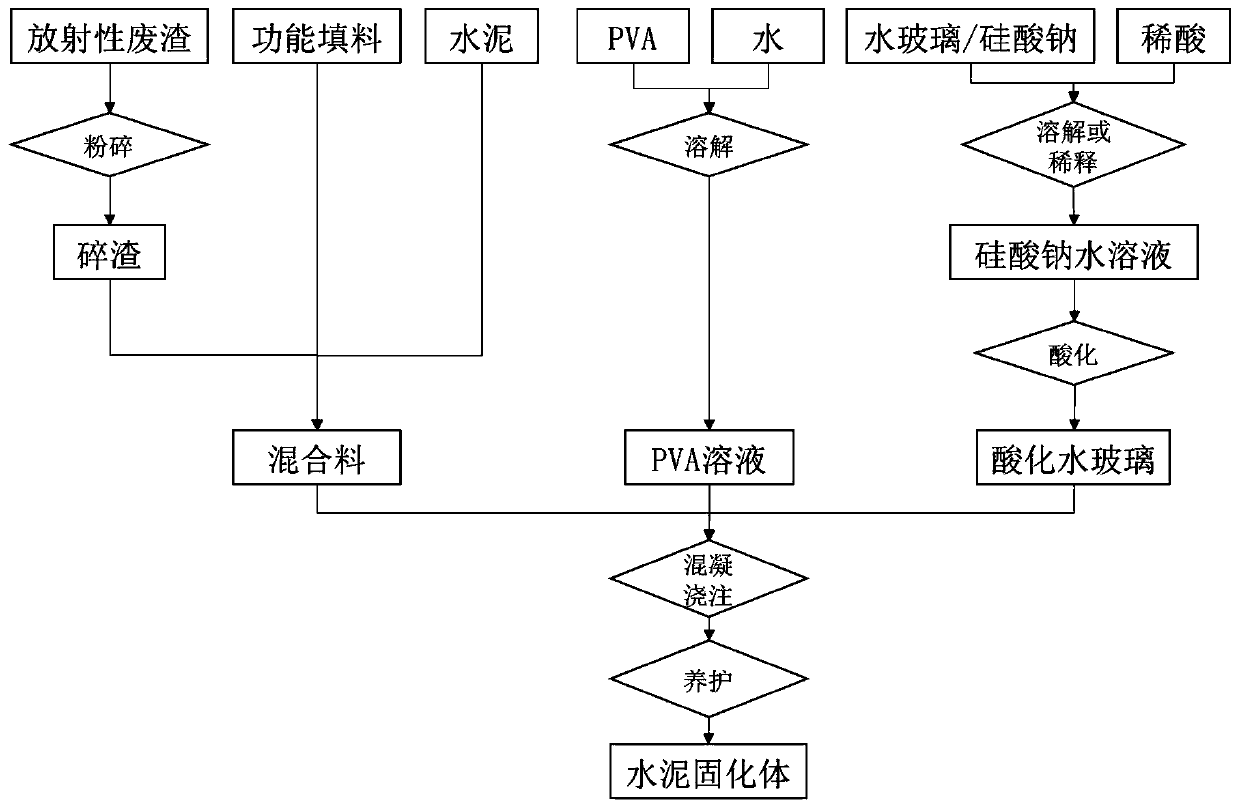

A solidification method and radioactive technology, which is applied in the solidification field of radioactive waste residue, can solve problems such as difficulty in adapting to solidification needs, large cement content, and low containment capacity, and achieve low leaching rate, high reactivity, and reduced porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, slag from a uranium mine in Hunan is taken as a sample, and the sample is 0-300mm gangue.

[0047] Follow the steps below to solidify the sample to obtain a cement solidified body:

[0048] S1. Waste slag crushing: Before crushing, first dry the slag sample to a moisture content of 3.6wt%, and then use a jaw crusher to crush the slag into slag with a particle size of 0-5mm, which is an unselected particle size. continuous grading;

[0049] S2. Mixing ingredients: choose ordinary Portland cement with a strength grade of 52.5, use "activated clay and fly ash with a mass ratio of 1:2" as the functional filler, and the content of the functional filler with a particle size of less than 0.075mm is greater than 95 %, the mass ratio of slag, functional filler and cement is 70:15:15, and the mixture is obtained by stirring and mixing evenly;

[0050] S3. Acidified water glass: select brand LGY402, the liquid sodium silicate (water glass) that modulus is 3.2...

Embodiment 2

[0058] In this embodiment, leaching slag from a water treatment plant of a uranium mine in Hunan is taken as a sample, the particle size of the sample is 0-1.0mm, and the water content is 8%-15%.

[0059] Follow the steps below to solidify the sample to obtain a cement solidified body:

[0060] S1. Waste slag crushing: before crushing, spread the leaching slag to a thickness of 10mm-20mm, dry at 100-105°C for 2 hours, and then use a ball mill to disperse the leaching slag into broken slag;

[0061] S2. Mixing of ingredients: Ordinary Portland cement with a strength grade of 52.5 is selected, and "the mass ratio of activated clay, fly ash and granulated blast furnace slag powder is 1:1:1" is used as the functional filler, and the particle size of the functional filler is The content of less than 0.075mm is greater than 95%. The mass ratio of slag, functional filler and cement is 65:20:15 for batching, and the mixture is obtained by stirring and mixing evenly;

[0062] S3. Acid...

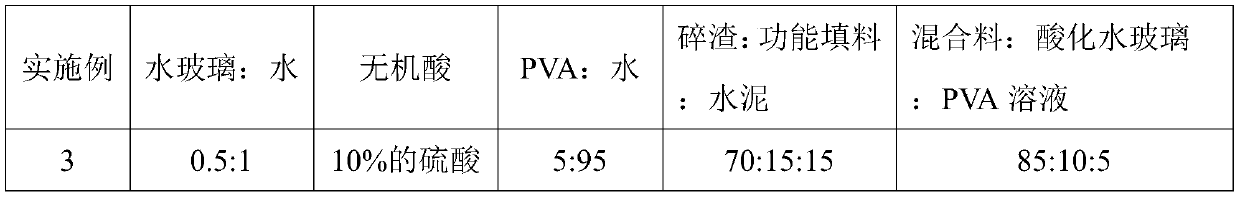

Embodiment 3~11

[0066] Compared with Example 1, Examples 3-11 differ in that the preparation conditions are shown in Table 3, and the others are basically the same as Example 1, and will not be repeated here.

[0067] The preparation condition of table 3 embodiment 3~12

[0068]

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com