Bipolar plate, preparation method thereof and fuel cell

A fuel cell and bipolar plate technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of losing the advantages of carbon fiber materials, destroying the mechanical properties of carbon fibers, affecting the electrical conductivity of bipolar plates, etc. Good sex and strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

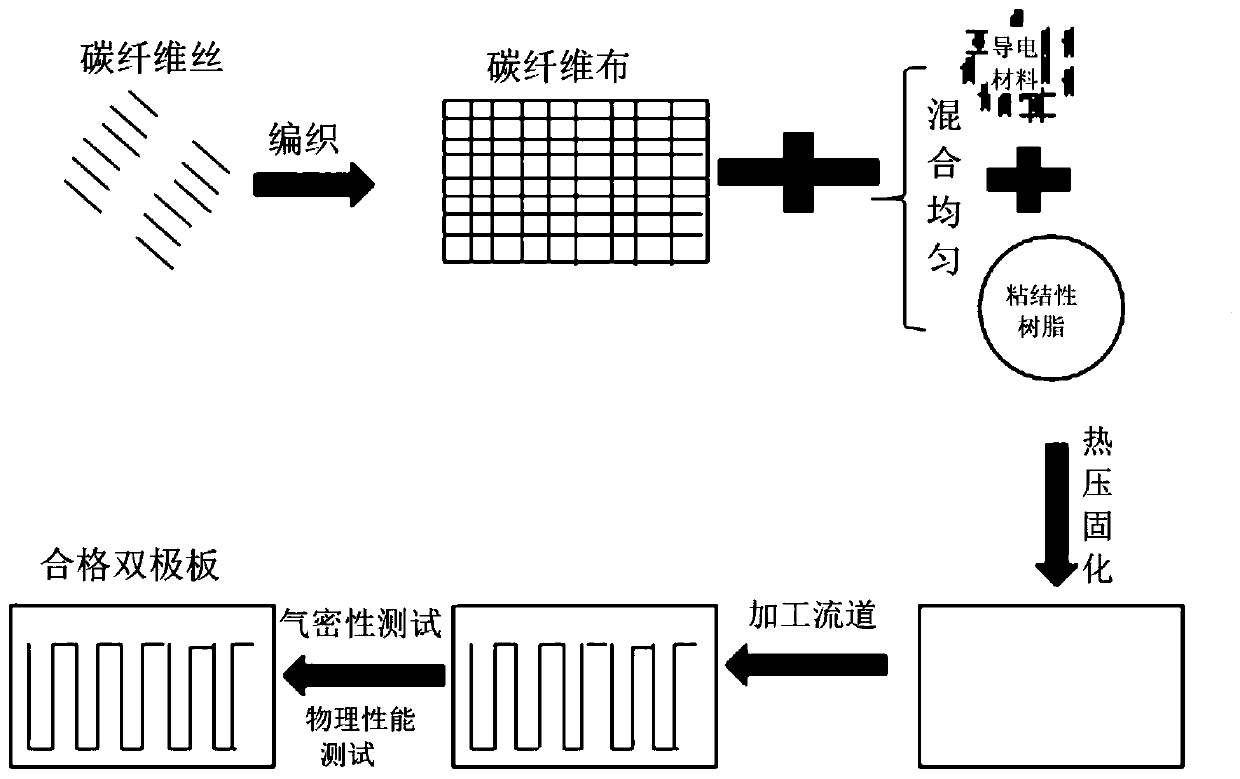

[0049] On the one hand, an embodiment of the present invention provides a method for preparing a bipolar plate, see figure 1 As shown, the preparation method specifically includes the following steps:

[0050] S1: Steps of making carbon fiber structure

[0051] Here, the carbon fiber structure in this embodiment is carbon fiber cloth.

[0052] Preferably, this step is specifically weaving carbon fiber filaments into carbon fiber cloth of corresponding size. Preferably, the thickness of the carbon fiber cloth is 0.14-0.22 mm, preferably 0.18-0.20 mm. Preferably, in this step, the carbon fiber filaments are polyacrylonitrile-based carbon fiber filaments; preferably, the carbon fiber filaments have a density of 1.75-1.85 g / cm 3 , preferably 1.78~1.82g / cm 3 , more preferably 1.80g / cm 3 . Preferably, the carbon fiber filaments have a diameter of 6.5-7.5 μm, preferably 6.8-7.2 μm, more preferably 7 μm. Preferably, the resistance of the carbon fiber filament is ≤33Ω / m.

[005...

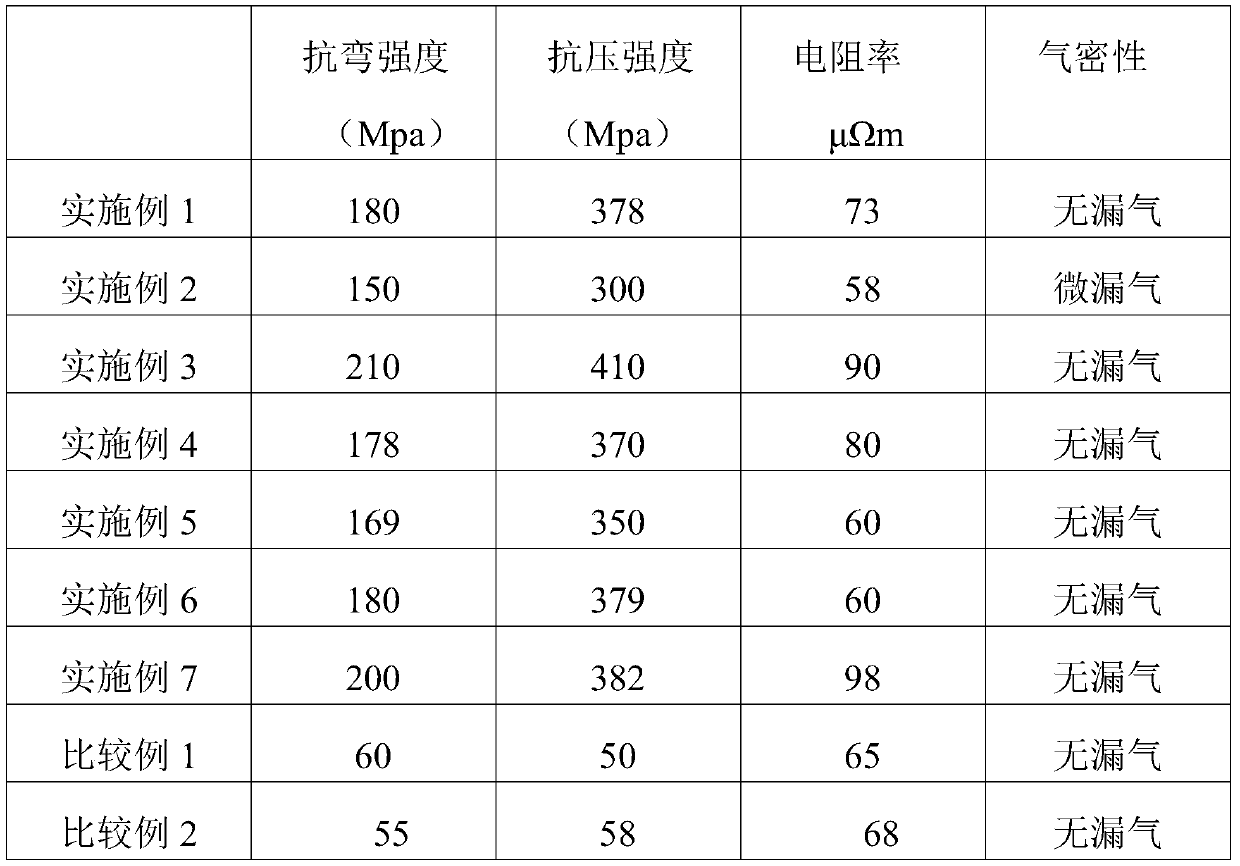

Embodiment 1

[0070] In this embodiment, a bipolar plate is prepared, and the specific preparation steps are as follows:

[0071] 1) Weaving polyacrylonitrile-based carbon fiber filaments into carbon fiber cloth. Among them, the density of polyacrylonitrile-based carbon fiber is 1.80g / cm 3 , diameter 7μm, resistance ≤33Ω / meter. The thickness of the carbon fiber cloth is 0.18mm.

[0072] 2) Disperse the premixed material of graphene and phenolic resin through a three-roller machine, so that the graphene and phenolic resin are evenly mixed to obtain a binder (ie, an adhesive resin mixed with a conductive material). Wherein, in the binder, the mass fraction of the graphene is 2.3%

[0073] 3) Place 5 layers of carbon fiber cloth in the mold; during the process of placing the carbon fiber cloth, it is necessary to brush the adhesive on the carbon fiber cloth placed on the previous layer, so that any two adjacent layers of carbon fiber cloth pass through the adhesive layer connect.

[0074]...

Embodiment 2

[0078] In this embodiment, a bipolar plate is prepared, and the specific preparation steps are as follows:

[0079] 1) Weaving polyacrylonitrile-based carbon fiber filaments into carbon fiber cloth. Among them, the density of polyacrylonitrile-based carbon fiber is 1.80g / cm 3 , diameter 7μm, resistance ≤33Ω / meter. The thickness of the carbon fiber cloth is 0.18mm.

[0080] 2) Disperse the premixed material of graphene and phenolic resin through a three-roller machine, so that the graphene and phenolic resin are evenly mixed to obtain a binder (ie, an adhesive resin mixed with a conductive material). Wherein, in the binder, the mass fraction of the graphene is 2.3%

[0081] 3) Place 3 layers of carbon fiber cloth in the mold; during the process of placing the carbon fiber cloth, it is necessary to brush the adhesive on the carbon fiber cloth placed on the previous layer, so that any adjacent two layers of carbon fiber cloth pass through the adhesive layer connect.

[0082]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com