A current collector and its preparation method and application

A technology of current collectors and semiconductors, applied in the field of current collectors and their preparation, can solve the problem of not being able to take both safety performance and rate performance into consideration, and achieve the effects of taking both safety performance and rate performance into consideration, improving safety performance, and improving energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

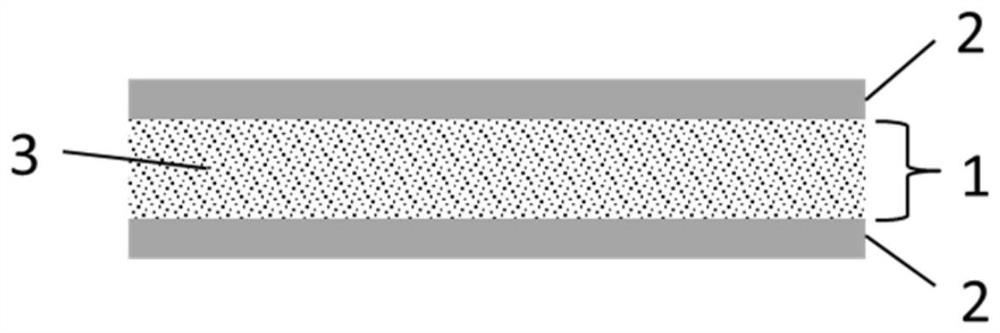

Image

Examples

Embodiment 1

[0049] In the current collector provided in this embodiment, the composite film layer is obtained by 99 parts of polyethylene terephthalate PET and 1 part of silicon, wherein the particle diameter of silicon is 10 nm, and the composite film layer is on the upper surface and the lower surface A metal aluminum layer is arranged as a positive electrode current collector material, and a metal copper layer is arranged on the upper surface and the lower surface of the composite film layer as a negative electrode current collector material.

[0050] The current collector can be prepared as follows:

[0051] 1) Melting and kneading the raw materials of the above-mentioned composite film layer to obtain a slurry, and extruding through an extrusion device to obtain a composite film layer with a thickness of 3 μm.

[0052] After testing, the normal temperature (25°C) sheet resistance R1 of the composite film layer is 1.17*10 9 Ω / sq.

[0053] 2) A 2 μm thick metal aluminum layer is coat...

Embodiment 2

[0058] In the current collector provided in this embodiment, the composite film layer is obtained by 99 parts of polyethylene terephthalate PET and 1 part of silicon, wherein the particle diameter of silicon is 100 nm, and the composite film layer is on the upper surface and the lower surface A metal aluminum layer is arranged as a positive electrode current collector material, and a metal copper layer is arranged on the upper surface and the lower surface of the composite film layer as a negative electrode current collector material.

[0059] The current collector can be prepared as follows:

[0060] 1) Melting and kneading the raw materials of the above-mentioned composite film layer to obtain a slurry, and extruding through an extrusion device to obtain a composite film layer with a thickness of 3 μm.

[0061] After testing, the normal temperature (25°C) sheet resistance R1 of the composite film layer is 1.62*10 9 Ω / sq.

[0062] 2) A 2 μm-thick metal aluminum layer is coa...

Embodiment 3

[0067] In the current collector provided in this embodiment, the composite film layer is obtained by 99 parts of polyethylene terephthalate PET and 1 part of silicon, wherein the particle diameter of silicon is 500nm, and the composite film layer is on the upper surface and the lower surface A metal aluminum layer is arranged as a positive electrode current collector material, and a metal copper layer is arranged on the upper surface and the lower surface of the composite film layer as a negative electrode current collector material.

[0068] The current collector can be prepared as follows:

[0069] 1) Melting and kneading the raw materials of the above-mentioned composite film layer to obtain a slurry, and extruding through an extrusion device to obtain a composite film layer with a thickness of 3 μm.

[0070] After testing, the normal temperature (25°C) sheet resistance R1 of the composite film layer is 2.31*10 9 Ω / sq.

[0071] 2) A 2 μm thick metal aluminum layer is coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com