Online grid type itinerant detection system for gas components at SCR outlet

A technology of roving detection and gas composition, applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of poor representation of NOx concentration measurement data, inability to realize optimal adjustment of ammonia injection grid partitions, and inability to meet the fine adjustment of SCR system, etc. , to achieve the effect of improving reliability and stability, improving stability and reliability, and maintaining stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments, but the claimed scope of the present invention is not limited to the following specific embodiments.

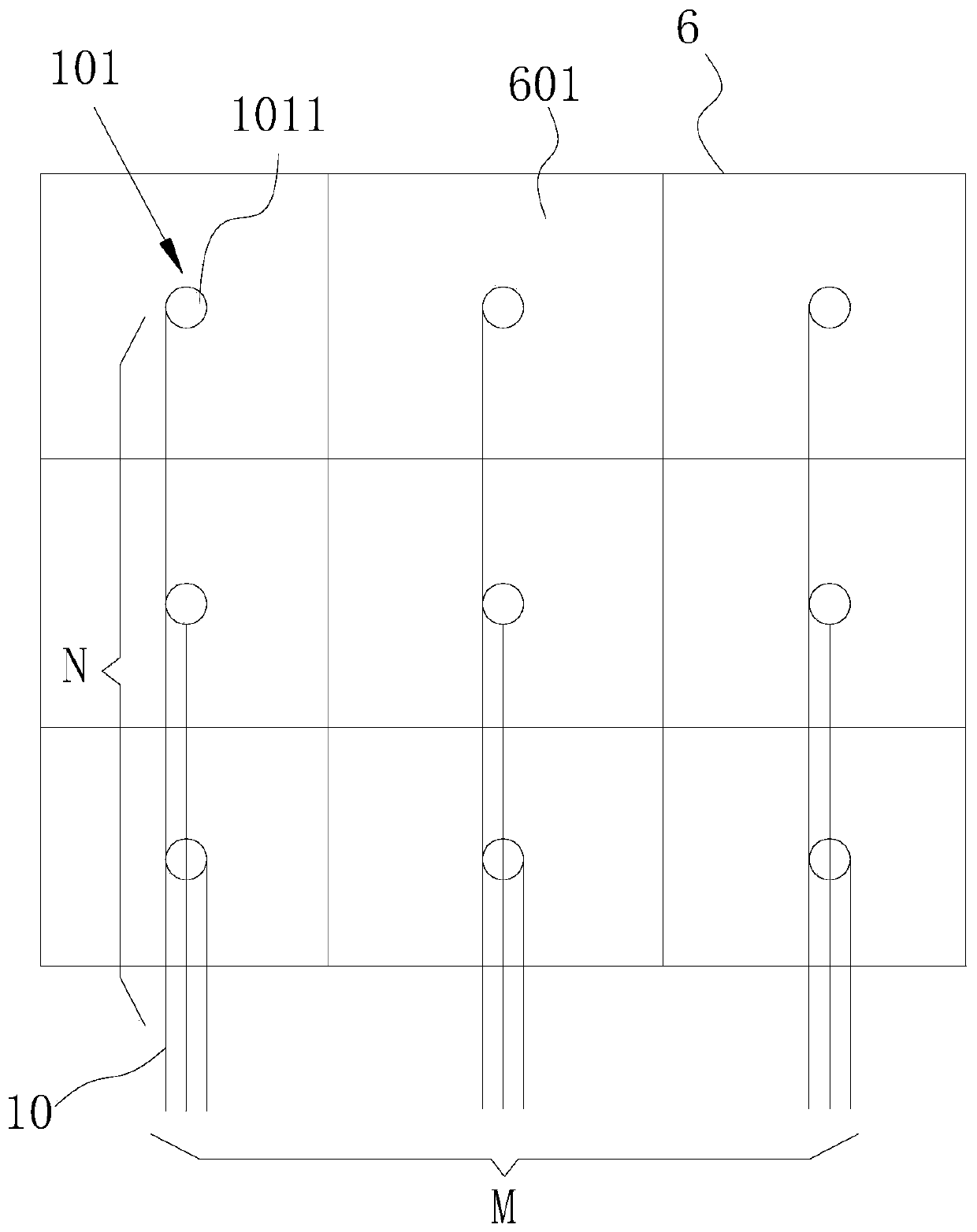

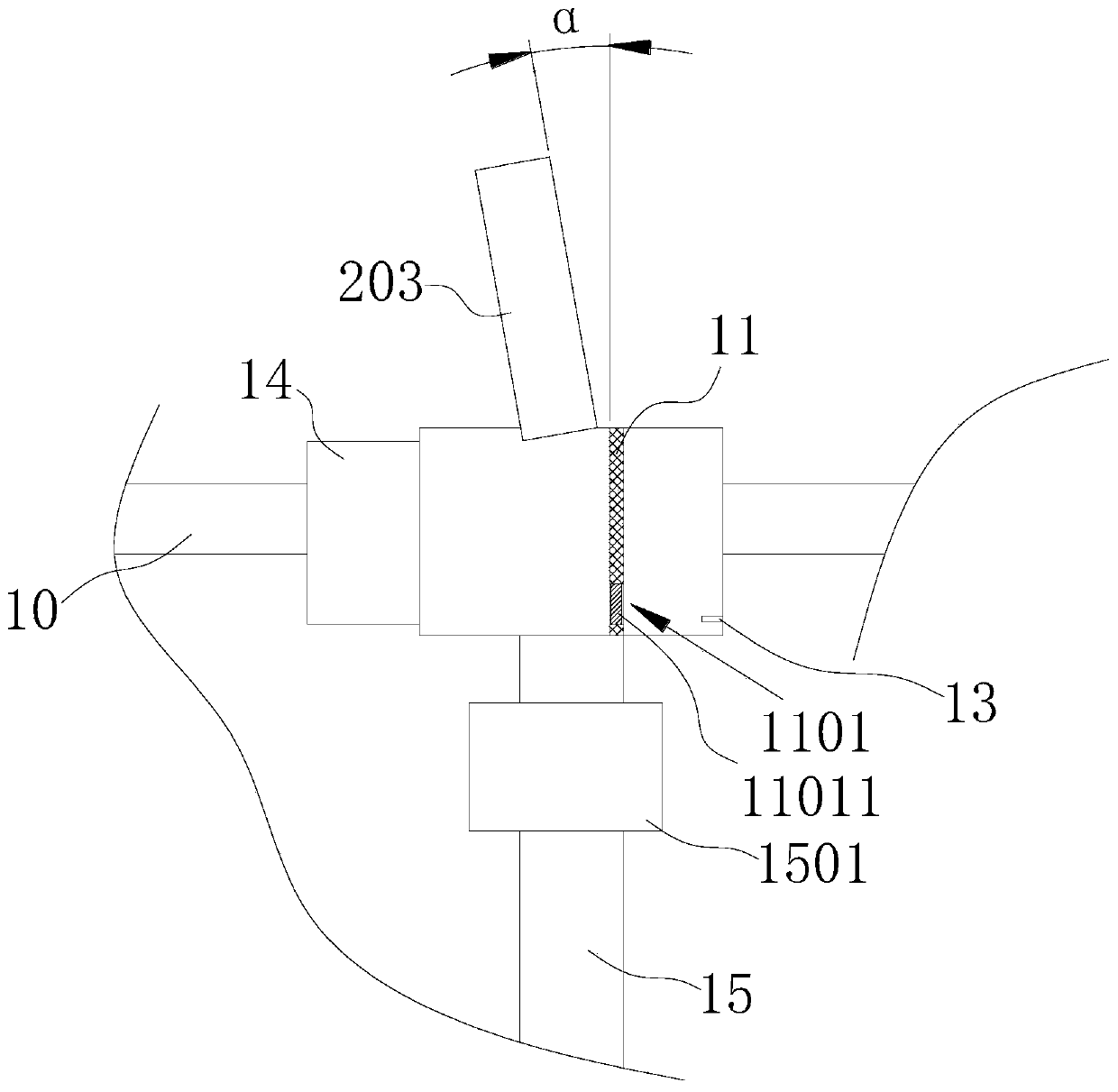

[0043] refer to figure 1 , this embodiment discloses an on-line grid-style circuit detection system for SCR outlet gas components, including a sampling device 1, a backflushing device 2, a switching control device 3, an analysis device 4, and a host computer 5, and the sampling device 1 is arranged in the flue gas channel. 6 and at the outlet of the SCR system 7 .

[0044] refer to figure 1 , the flue gas passage 6 is communicated with the boiler 8 , the SCR system 7 includes several groups of SCR catalyst modules 701 , and the several SCR catalyst modules 701 are arranged at intervals along the flue gas passage 6 .

[0045] refer to figure 1 In the flue gas channel 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com