Hydrophilic membrane and preparation method thereof

A hydrophilic membrane, hydrophilic technology, applied in the direction of cellulose/protein conjugated rayon, conjugated synthetic polymer rayon, fiber type, etc., can solve problems such as toxic shock syndrome, skin allergic reactions, etc. , to achieve the effect of high water absorption and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

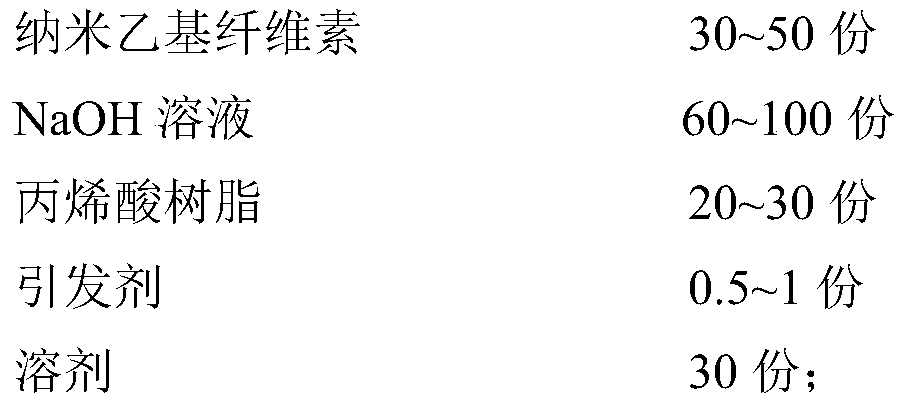

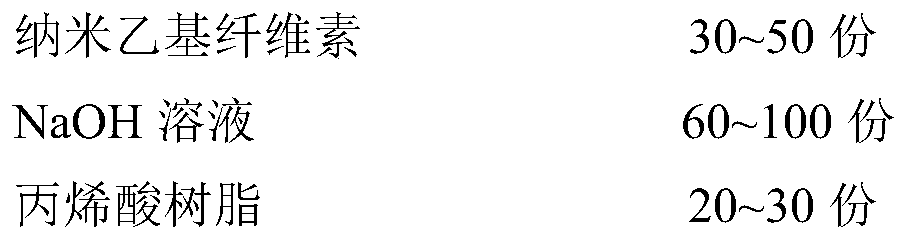

[0033] Add 30 parts of nano ethyl cellulose to 60 parts of 10% NaOH solution and stir well, then add 20 parts of butyl acrylate, 30 parts of toluene, and then add 0.5 parts of benzoyl peroxide, mix well and place at 80°C Under constant temperature reaction for 30min. After filtering, dry at 85° C. for 12 hours in a blast drying oven to break the resin into particles to obtain the desired modified nanofibers.

[0034] The preparation method of the water-absorbing fiber: mix 20 parts of modified nanofibers, 20 parts of polyethylene, and 15 parts of polypropylene evenly, and then solidify and form the required water-absorbing fibers through electrospinning at 280°C.

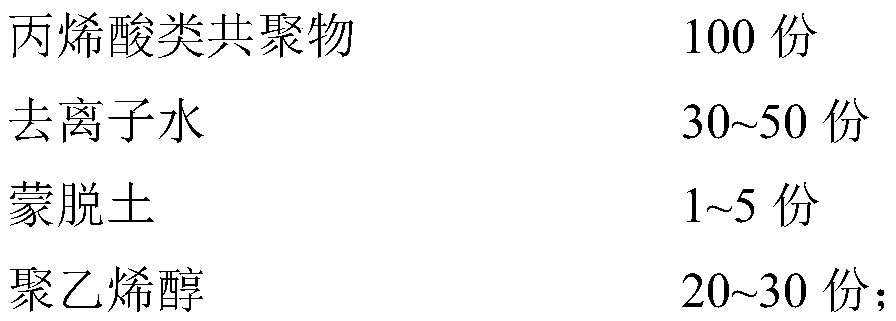

[0035] Preparation method of hydrophilic coating: add 20 parts of PVA to 30 parts of deionized water, then stir and dissolve completely at 70°C, cool to room temperature, add the solution to SK-1170, then add 1 part of montmorillonite, emulsify In half an hour, the desired hydrophilic coating is obtained.

[0036]...

Embodiment 2

[0038] Add 50 parts of nano ethyl cellulose to 80 parts of 10% NaOH solution and stir well, then add 30 parts of butyl acrylate, 30 parts of toluene, and then add 1 part of benzoyl peroxide, mix well and place at 80°C Under constant temperature reaction for 30min. After filtering, dry at 85° C. for 12 hours in a blast drying oven to break the resin into particles to obtain the desired modified nanofibers.

[0039] The preparation method of the water-absorbent fiber: 40 parts of modified nanofibers, 30 parts of polyethylene, and 25 parts of polypropylene are evenly mixed, and then the required water-absorbent fibers are obtained by curing and forming through electrospinning at 280°C.

[0040] Preparation method of hydrophilic coating: Add 25 parts of PVA to 30 parts of deionized water, then stir and dissolve completely at 70°C, cool to room temperature, add the solution to SK-1170, add 5 parts of montmorillonite, emulsify In half an hour, the desired hydrophilic coating is obt...

Embodiment 3

[0043] Add 40 parts of nano-ethyl cellulose to 100 parts of 10% NaOH solution and stir well, then add 25 parts of butyl acrylate, 30 parts of toluene, and then add 0.8 parts of benzoyl peroxide, mix well and place at 80°C Under constant temperature reaction for 30min. After filtering, dry at 85° C. for 12 hours in a blast drying oven to break the resin into particles to obtain the desired modified nanofibers.

[0044] The preparation method of water-absorbent fiber: mix 30 parts of modified nanofiber, 25 parts of polyethylene, and 20 parts of polypropylene evenly, and then solidify and form the required water-absorbent fiber through electrospinning process at 280°C.

[0045] Preparation method of hydrophilic coating: Add 30 parts of PVA to 30 parts of deionized water, then stir and dissolve completely at 70°C, cool to room temperature, add the solution to SK-1170, add 4 parts of montmorillonite, emulsify In half an hour, the desired hydrophilic coating is obtained.

[0046] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com