Electroplating liquid for electroplating pure cobalt and application thereof

A technology of electroplating solution and solution, which is applied in the field of applied electrochemistry to achieve the effect of electrical interconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Each component, content, and pH value of the electroplating solution for electroplating pure cobalt are as follows:

[0060] Base solution: CoSO 4 .7H 2 O, 80g / L

[0061] CoCl2 .6H 2 O, 10g / L

[0062] Boric acid: H 3 BO 3 ,20g / L

[0063] pH value: pH=4

[0064] Wetting agent: sodium dodecyl sulfate (SDS), 1.0g / L

[0065] Brightener: sodium saccharin, 1.0g / L

[0066] Accelerator: 2-mercaptobenzimidazole-5-sulfonate sodium dihydrate (MBIS), 0.050g / L

[0067] Complexing agent: dimethylglyoxime (DMG), 20000ppm.

[0068] Specifically, first weigh the CoSO 4 .7H 2 O, CoCl 2 .6H 2 O was added to water, stirred, and after being fully dissolved, boric acid was added. Thereafter, gradually add wetting agent, brightener, accelerator, and complexing agent, stir well, and adjust the pH to 4 with sulfuric acid and sodium hydroxide to obtain an electroplating solution for electroplating pure cobalt.

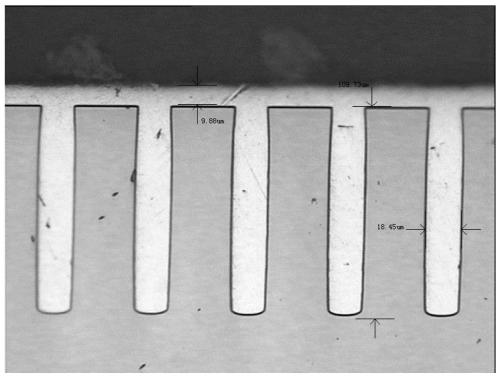

[0069] In order to evaluate the effect of using the electroplating s...

Embodiment 2

[0072] Each component, content, and pH value of the electroplating solution for electroplating pure cobalt are as follows:

[0073] Base solution: CoSO 4 .7H 2 O, 60g / L

[0074] CoCl 2 .6H 2 O, 10g / L

[0075] Boric acid: H3BO3, 30g / L

[0076] pH value: pH=5

[0077] Wetting agent: SDS, 1.2g / L

[0078] Brightener: sodium saccharin, 0.8g / L

[0079] Accelerator: MBIS, 0.030g / L

[0080] Complexing agent: cyclohexanone oxime (CHO), 1000ppm

[0081] Its specific preparation method is the same as in Example 1, and its description is omitted here.

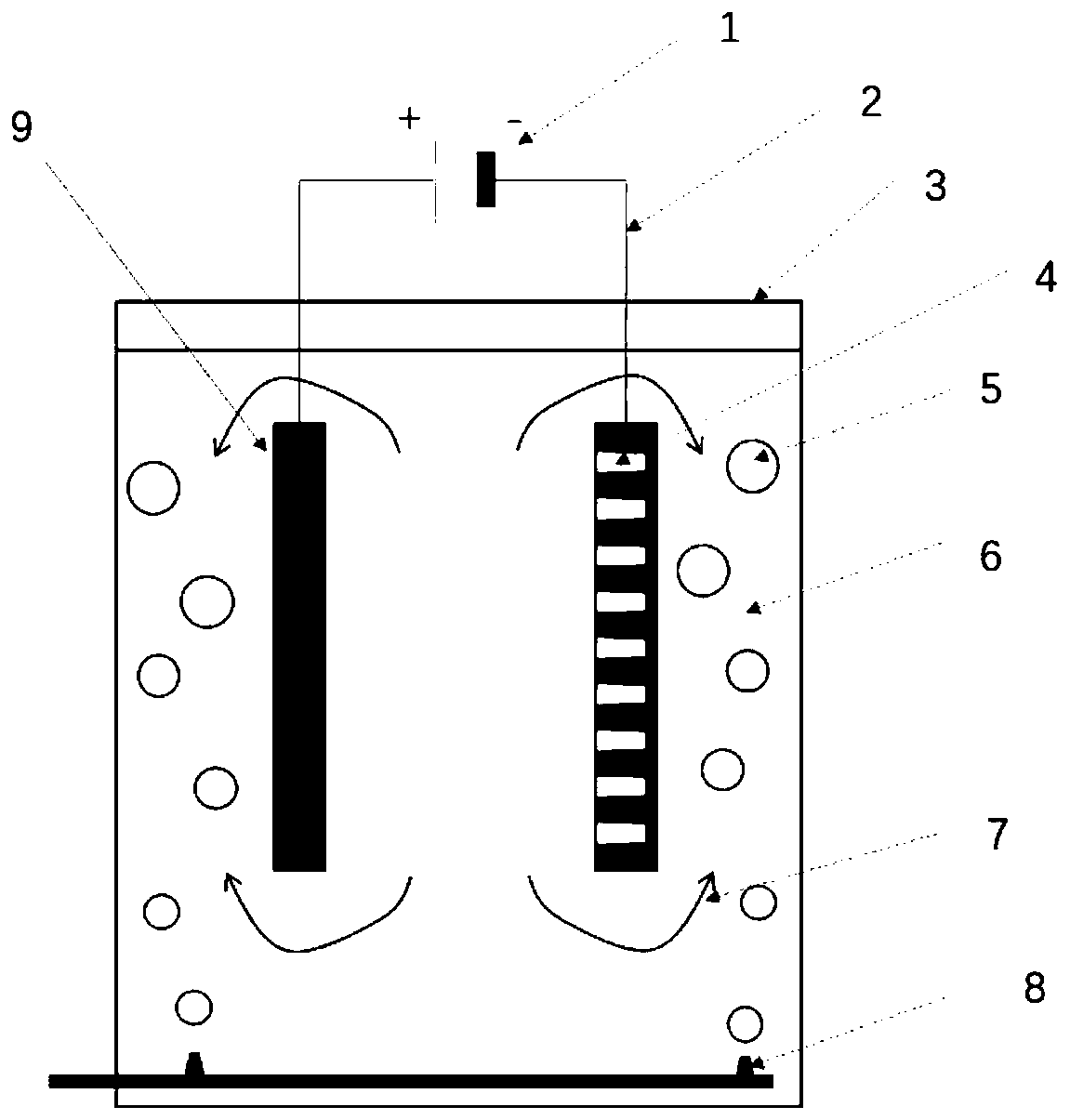

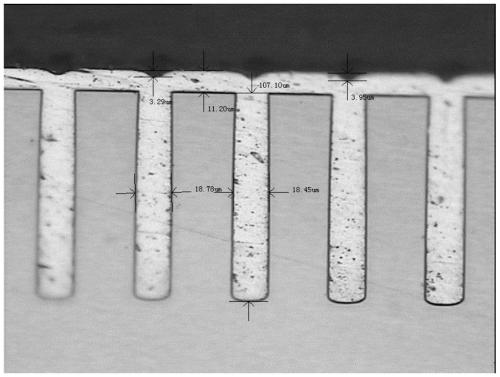

[0082] In order to evaluate the effect of using the electroplating solution for electroplating pure cobalt of the present invention, samples with through-silicon vias (TSVs) were electroplated using it. Specifically, the sample was rinsed, vacuumed, and then the sample was figure 1 The schematic diagram of the device shown is installed in the electroplating tank, and the pure nitrogen gas stirring is turned on. The nitrogen gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com