A kind of molybdenum/titanium alloy film etchant composition and application thereof

An etching solution and composition technology, applied in the field of titanium alloy thin film etching solution composition, can solve the problems of non-standard display quality, molybdenum residue, increased side corrosion, etc., and achieve the effect of avoiding excessive side corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Fabrication of Bilayer Thin Films Containing Titanium and Molybdenum Layers

[0025] Using 1.0cm×1.0cm silicon as the substrate, a layer of molybdenum is magnetron sputtered on its surface to form a barrier layer, and then a layer of titanium is magnetron sputtered to obtain a silicon / molybdenum / titanium double-layer metal film layer. for subsequent etching experiments. Here, in order to better illustrate the technical effect of the present invention, the thickness of the molybdenum film layer is 50 μm, and the thickness of the titanium film layer is 800 μm.

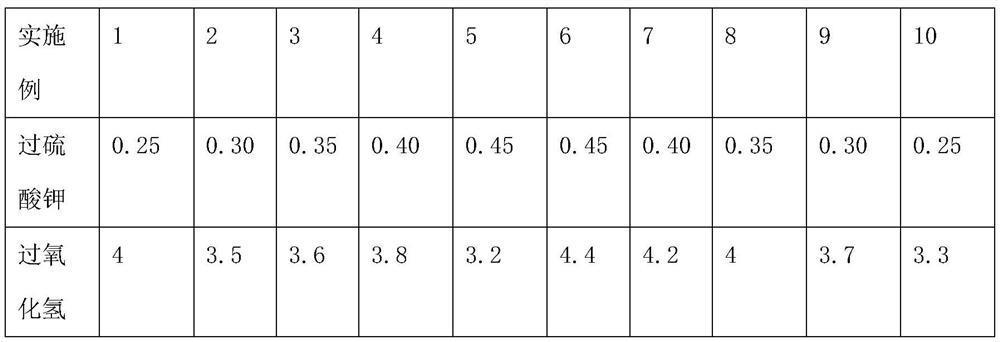

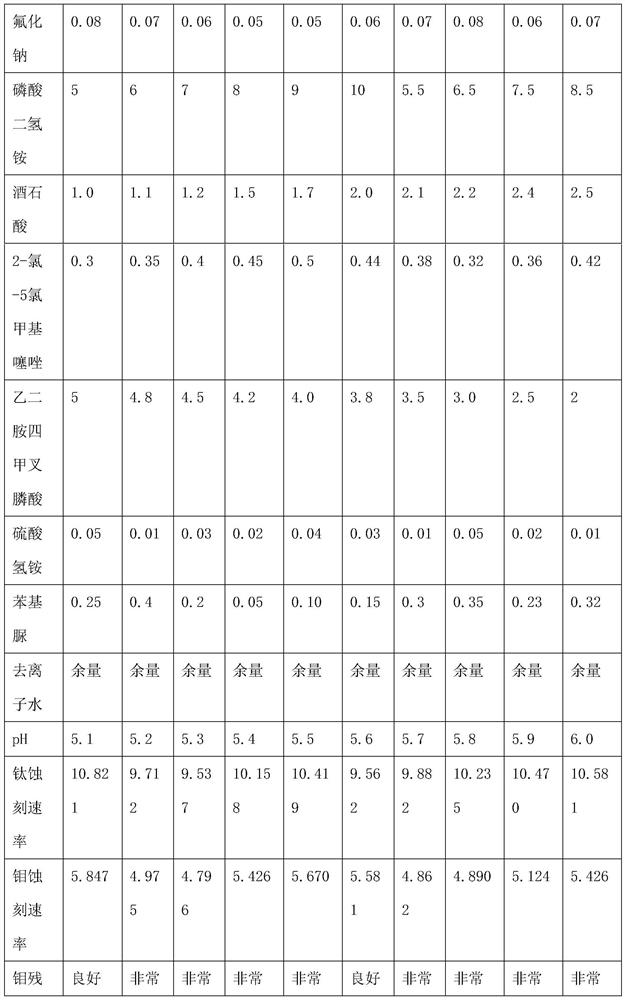

Embodiment 1-10

[0027] The etching liquid composition shown in Table 1 was put into each reaction container, and the temperature was stabilized in the thermostat kept at 45 degreeC. While stirring the etching solution composition by a stirrer, the prepared molybdenum / titanium substrate was etched for 120s, washed with water and dried, and the etching rate (μm / min) was calculated by the weight loss method:

[0028] μ(Ti)=Δm(Ti) / (1.0cm×1.0cm×4.5g / cm 3 ×120 / 60)×10 -3 ,

[0029] μ(Mo)=Δm(Mo) / (1.0cm×1.0cm×10.28g / cm 3 ×120 / 60)×10 -3 .

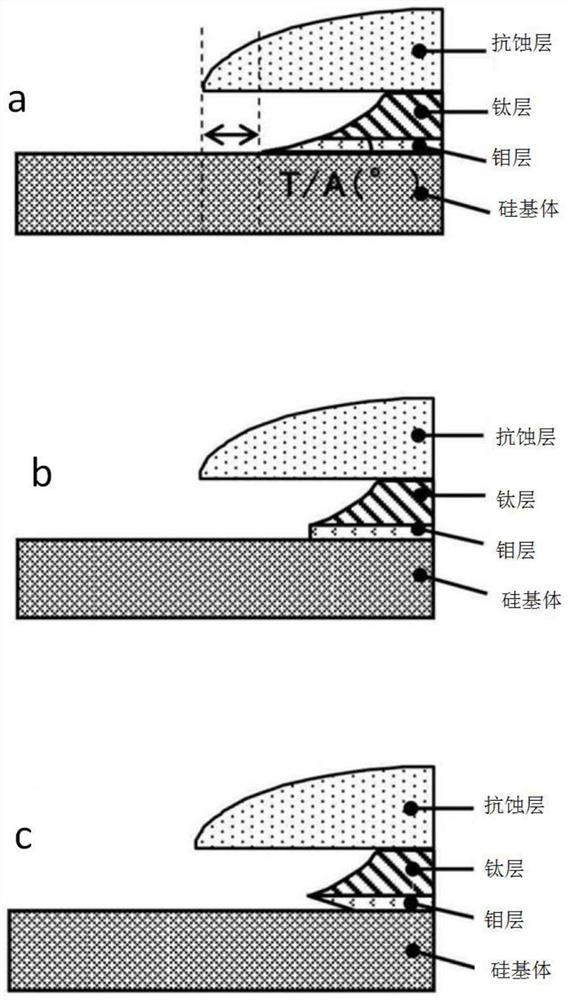

[0030] Confirm the cross-sectional shape by SEM, and evaluate various indicators such as the amount of side corrosion, taper angle, molybdenum residue, molybdenum undercut, and CD Loss. The indicators are shown in Table 1. The molybdenum residues in the table are divided into very good, good and poor. The situation of molybdenum undercut in the table is divided into very good, good and bad, corresponding to the figure 1 a, b, c in.

[0031] A CD Loss (=a×2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com