Heat treatment method of thin-specification quenching and tempering 07MnNiMoDR steel plate

A heat treatment method and thin-gauge technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as reduced elongation, upper limit, and lower limit of steel plate strength, and achieve stable product performance, excellent toughness, and moderate strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 07

[0021] The thickness of the 07MnNiMoDR steel plate in this embodiment is 10mm.

[0022] (1) Quenching process: Quenching temperature 840°C, total heating time (PLC+0) min, and 3500m into the quenching machine after being out of the furnace 3 The water volume per hour is water-cooled, the roll speed of the quenching machine is 18m / min, and the steel plate is cooled to room temperature.

[0023] (2) Tempering process: the tempering temperature is 610°C, the total heating time is 5.5min / mm, and the furnace is air-cooled to room temperature.

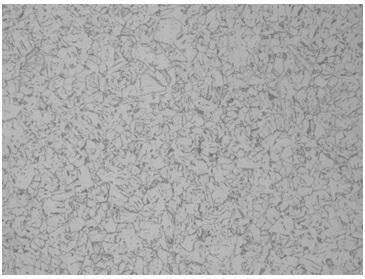

[0024] The grain size of the heat-treated steel plate in this example is grade 9.5, and its metallographic structure is tempered bainite + ferrite, of which tempered bainite accounts for 93%. The mechanical properties are shown in Table 1.

Embodiment 2

[0026] The thickness of the 07MnNiMoDR steel plate in this embodiment is 14mm.

[0027] (1) Quenching process: Quenching temperature 850°C, total heating time (PLC+10) min, 3600m into the quenching machine after being out of the furnace 3 The water volume per hour is water-cooled, the roll speed of the quenching machine is 20m / min, and the steel plate is cooled to room temperature.

[0028] (2) Tempering process: the tempering temperature is 620°C, the total heating time is 5.0 min / mm, and the furnace is air-cooled to room temperature.

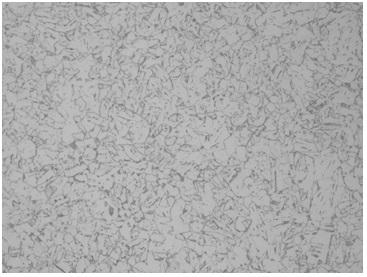

[0029] The grain size of the heat-treated steel plate in this example is 8.5, and its metallographic structure is tempered bainite + ferrite, of which tempered bainite accounts for 92%. The mechanical properties are shown in Table 1.

Embodiment 3

[0031] The thickness of the 07MnNiMoDR steel plate in this embodiment is 16mm.

[0032] (1) Quenching process: Quenching temperature 860°C, total heating time (PLC+5) min, and 3900m into the quenching machine after being out of the furnace 3 The water volume per hour is water-cooled, the roll speed of the quenching machine is 26m / min, and the steel plate is cooled to room temperature.

[0033] (2) Tempering process: the tempering temperature is 630°C, the total heating time is 4.8 min / mm, and the furnace is air-cooled to room temperature.

[0034] The grain size of the heat-treated steel plate in this example is 9.0, and its metallographic structure is tempered bainite + ferrite, of which tempered bainite accounts for 91%. The mechanical properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com