Lubricating grease and preparation method thereof

A technology of lubricating grease and thickener, which is applied in the field of lubricating grease and its preparation, can solve problems such as poor adsorption, product production yield and efficiency impact, and achieve good adhesion, not easy to lose, and suitable for industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

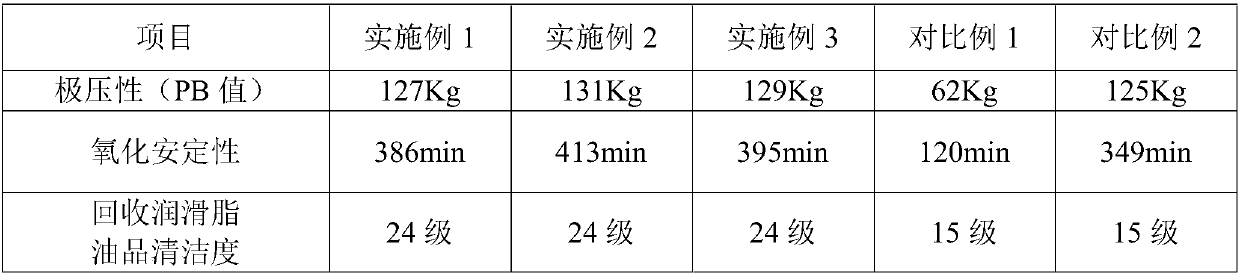

Examples

preparation example Construction

[0053] The preparation method of the lubricating grease of one embodiment is one of the preparation methods of the above-mentioned lubricating grease, comprising the steps of:

[0054] Under the condition of 70°C to 80°C, base oil, thickener and polymetallic oxygen cluster compound are mixed to obtain lubricating grease.

[0055] Wherein, the base oil includes biological oil and synthetic oil, and the mass fraction of the base oil is 77-92 parts. Further, the mass fraction of bio-oil is 60-70 parts; the mass fraction of synthetic oil is 17-22 fractions.

[0056] Further, bio-oil includes vegetable oil and animal oil. Furthermore, the vegetable oil is selected from at least one of castor oil, sunflower oil and soybean oil; the animal oil is selected from at least one of tallow, lard and sheep oil. Specifically, the mass parts of vegetable oil are 30-35 parts; the mass parts of animal oil are 30-35 parts. Wherein, castor oil, sunflower oil and soybean oil are all liquid, tall...

Embodiment 1

[0074] The preparation steps of the grease of the present embodiment are as follows:

[0075] (1) In parts by mass, 30 parts of castor oil, 30 parts of tallow, 9 parts of neopentyl glycol ester and 8 parts of pentaerythritol ester are mixed evenly, added to the reaction kettle, and 5 parts of polymetallic oxygen clusters are added in turn Compound, 4 parts of sebacic acid, 2 parts of salicylic acid, 0.3 part of alum and 3 parts of 12-hydroxylithium stearate, and then the reaction kettle was heated to 70°C and stirred at a speed of 50r / min for 30min to obtain a premixed things.

[0076] (2) In parts by mass, 1 part of sodium hydroxide is dissolved in 1 part of soapy water to obtain an alkaline solution; the alkaline solution and the premix are added to the reactor and mixed evenly, and then the reactor is heated and pressurized Saponify at 170°C and 0.5Mpa for 70min at constant pressure, then dehydrate at constant pressure for 20min, dehydrate for 10min while degassing, and co...

Embodiment 2

[0079] The preparation steps of the grease of the present embodiment are as follows:

[0080] (1) In terms of parts by mass, 32 parts of castor oil, 32 parts of tallow, 10 parts of neopentyl glycol ester and 9 parts of pentaerythritol ester are mixed uniformly, added to the reaction kettle, and 6 parts of polymetallic oxygen clusters are sequentially added compound, 5 parts of sebacic acid, 3 parts of salicylic acid, 0.5 part of alum and 4 parts of 12-hydroxylithium stearate, and then the reaction kettle was heated to 75°C and stirred at a speed of 55r / min for 35min to obtain a premixed things.

[0081] (2) In terms of parts by mass, 1 part of sodium hydroxide is dissolved in 1 part of soapy water to obtain an alkaline solution; the alkaline solution is added to the reactor and mixed with the premix evenly, and then the reactor is heated and pressurized Saponify at 175°C and 0.6Mpa for 75min at constant pressure, then dehydrate at constant pressure for 25min, dehydrate for 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com