A kind of flame-retardant polylactic acid composite material and preparation method thereof

A technology of composite materials and polylactic acid, which is applied in the field of flame retardant materials, can solve problems such as insufficient environmental protection, achieve the effects of reducing consumption, reducing environmental burden, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

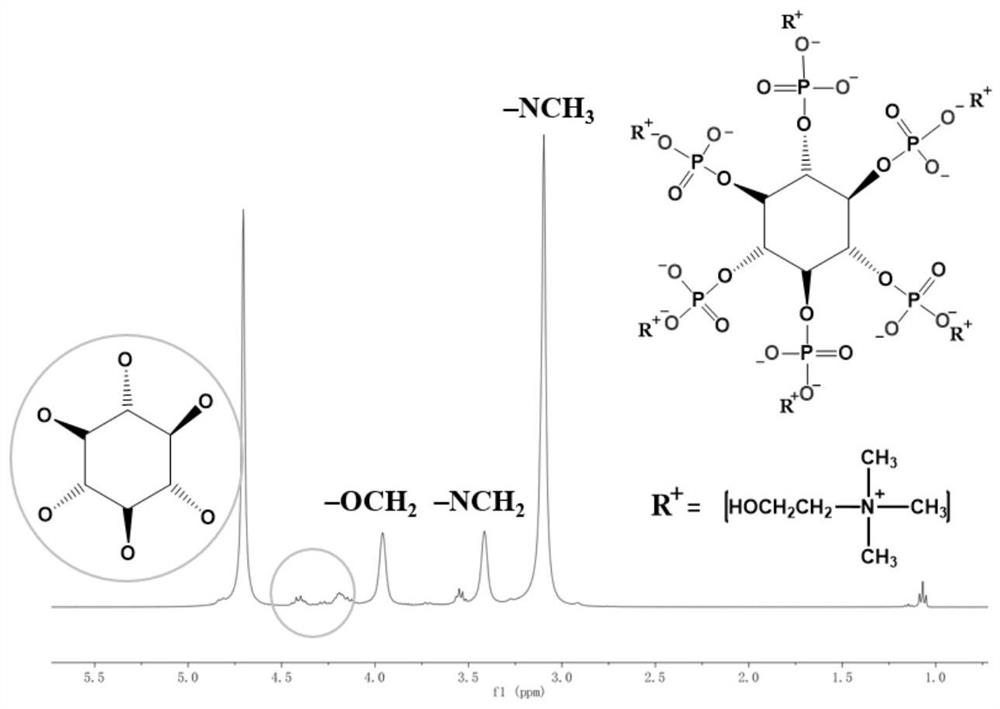

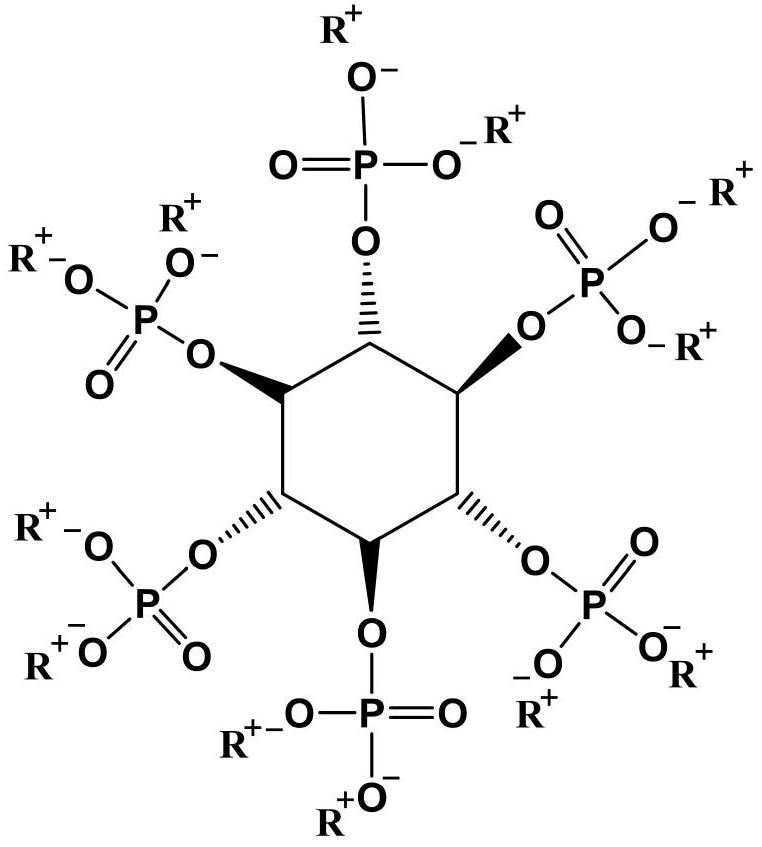

[0035] A preparation method of phytic acid choline flame retardant, the steps are:

[0036] (1) 0.7mol sodium hydroxide and 0.7mol choline chloride were dissolved in 300g and 200g ethanol respectively, after the two solutions were mixed and reacted at normal temperature for 1h, suction filtration obtained the filtrate of choline hydroxide;

[0037] (2) Weigh 0.117mol phytic acid and dissolve it in 100g ethanol, mix the filtrate of the choline hydroxide obtained in step (1), react at normal temperature for 1h, remove the supernatant, and then wash with ethanol several times to pH =7 and no change, and then dried for 10 hours under the conditions of temperature 80° C. and pressure −0.08 MPa to obtain a phytic acid choline flame retardant, denoted as CPA1.

Embodiment 2

[0039] A preparation method of a green environment-friendly flame retardant, the steps are:

[0040](1) 0.7mol sodium hydroxide and 0.7mol choline chloride are dissolved in 300g and 200g methanol respectively, after reacting at normal temperature for 8h, suction filtration obtains the filtrate of choline hydroxide;

[0041] (2) Take 0.1053mol phytic acid and dissolve it in 100g methanol, react at normal temperature for 12h, get the filtrate of the choline hydroxide obtained in step (1) and mix, remove the supernatant, and then wash with ethanol several times to pH =7 and no change, and then dried for 10 hours under the conditions of temperature 80° C. and pressure −0.06 MPa to obtain phytic acid choline flame retardant, denoted as CPA2.

Embodiment 3

[0043] A preparation method of a green environment-friendly flame retardant, the steps are:

[0044] (1) 0.7mol sodium hydroxide and 0.7mol choline chloride are dissolved in 300g and 200g methanol respectively, after reacting at normal temperature for 3h, suction filtration obtains the filtrate of choline hydroxide;

[0045] (2) Weigh 0.0585mol phytic acid and dissolve it in 100g methanol, react at normal temperature for 10h, mix the filtrate of the choline hydroxide obtained in step (1), remove the supernatant, and then wash with ethanol several times to pH =7 and no change, and then dried for 10 hours under the conditions of temperature 80°C and pressure -0.1MPa to obtain phytic acid choline flame retardant, which is denoted as CPA3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com