A kind of method of synthesizing 2-isopropylnaphthalene

A technology of isopropylnaphthalene and an alkylating agent, applied in the field of synthesizing 2-isopropylnaphthalene, can solve the problems of low selectivity of 2-isopropylnaphthalene, low conversion rate of raw materials, etc., so as to improve catalytic efficiency and simplify Process flow, guaranteed conversion and selectivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] like figure 1 As shown, the device for synthesizing styrenated phenol in this embodiment includes a preheating tube, a metering pump, a microreactor (continuous flow microchannel reactor), and the microchannel cross-section equivalent diameter of the microreactor in this embodiment is 0.5mm , the length of the microchannel tube is 100m.

[0043] The steps of synthesizing styrenated phenol in the present embodiment are as follows:

[0044] (1) naphthalene is heated to 90 ℃ by preheater and kept warm, as fluid A; 2-bromopropane is used as fluid B at normal temperature; triethylamine heptachlorodialuminate ionic liquid is used as fluid C at normal temperature; wherein, The molar ratio of naphthalene:2-bromopropane:chloroaluminate ionic liquid is 1:1.04:0.6;

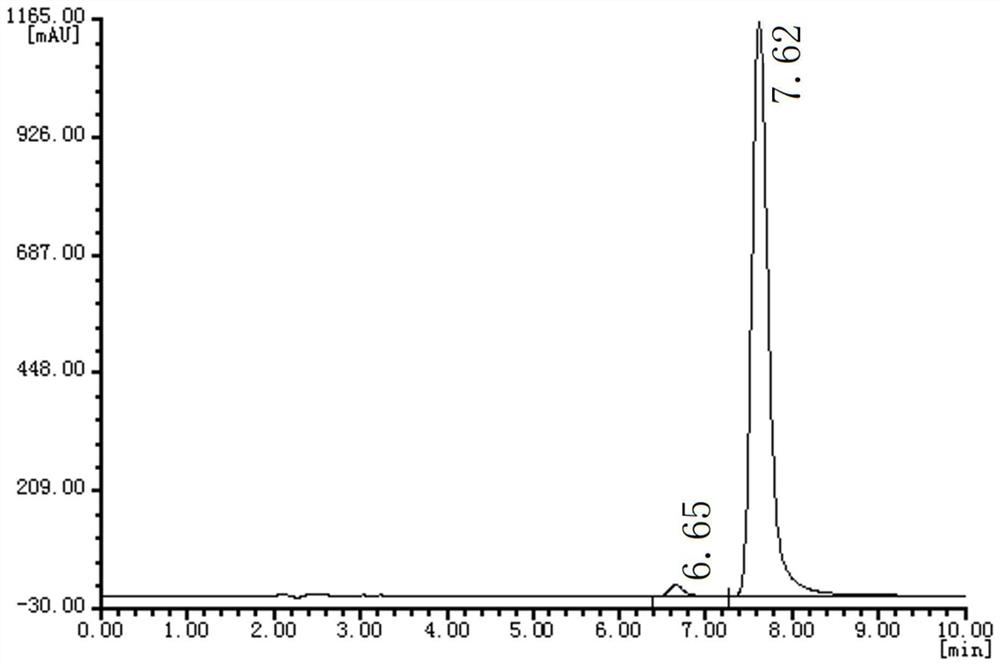

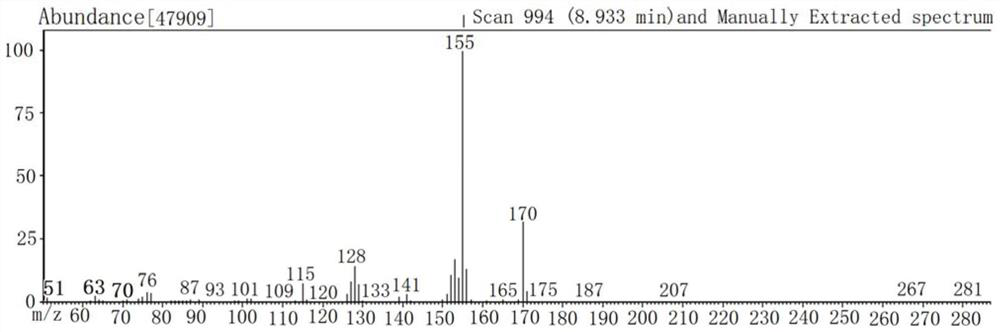

[0045] The volume flow rate of naphthalene is controlled by the metering pump to be 2.5ml / min, the volume flow rate of 2-bromopropane is 2.0ml / min and the volume flow rate of the chloroaluminate ionic liquid catalys...

Embodiment 2

[0050] like figure 1 As shown, the device for synthesizing styrenated phenol in this embodiment includes a preheating tube, a metering pump, a microreactor (continuous flow microchannel reactor), and the microchannel cross-section equivalent diameter of the microreactor in this embodiment is 0.6 mm , the length of the microchannel tube is 120m.

[0051] The steps of synthesizing styrenated phenol in the present embodiment are as follows:

[0052] (1) naphthalene is heated to 95 ℃ by a preheater and kept warm as fluid A; 2-bromopropane is used as fluid B at normal temperature; triethylamine heptachlorodialuminate ionic liquid is used as fluid C at normal temperature; wherein, The molar ratio of naphthalene:2-bromopropane:chloroaluminate ionic liquid is 1:1.04:1.2;

[0053] The volume flow rate of naphthalene is controlled by a metering pump to be 3ml / min, the volume flow rate of 2-bromopropane is 2.3ml / min, and the volume flow rate of chloroaluminate ionic liquid catalyst is ...

Embodiment 3

[0056] like figure 1 As shown, the device for synthesizing styrenated phenol in this embodiment includes a preheating tube, a metering pump, and a microreactor (continuous flow microchannel reactor). The microchannel cross-section equivalent diameter of the microreactor in this embodiment is 0.8 mm. , the length of the microchannel tube is 150m.

[0057] The steps of synthesizing styrenated phenol in the present embodiment are as follows:

[0058] (1) naphthalene is heated to 90 ℃ by preheater and kept warm, as fluid A; 2-bromopropane is used as fluid B at normal temperature; triethylamine heptachlorodialuminate ionic liquid is used as fluid C at normal temperature; wherein, The molar ratio of naphthalene:2-bromopropane:chloroaluminate ionic liquid is 1:1.04:1.8;

[0059] The volume flow rate of naphthalene was controlled by a metering pump to be 3.5ml / min, the volume flow rate of 2-bromopropane was 2.7ml / min, and the volume flow rate of the chloroaluminate ionic liquid cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com