Preparation method of high-temperature-resistant degradable plastic bowl

A technology of degrading plastics and high temperature resistance, applied in household components, applications, household appliances, etc., can solve the problems of poor heat resistance, long degradation time, plastic bowl deformation, etc., to improve film-forming and weather resistance, and enhance flow. properties and film-forming properties, and the effect of improving strength and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

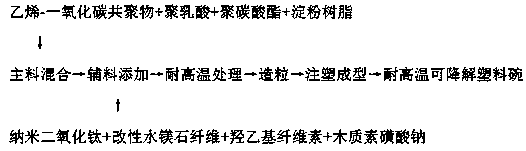

[0023] A method for preparing a high-temperature-resistant degradable plastic bowl, comprising the following steps:

[0024] Ethylene-carbon monoxide copolymer, polylactic acid, polycarbonate and starch resin are placed in the reactor, consisting of the following parts by weight: ethylene-carbon monoxide copolymer 57, polylactic acid 43, polycarbonate 36, starch resin 22, with 2 ℃ / min Stir continuously and heat until completely melted, keep stirring for 30 minutes, and fully stir to make the raw materials fully branched, improve the strength and heat resistance of the plastic bowl, avoid softening and deformation after heating, and the added raw materials are safe and healthy. It can be completely degraded without any residue, and the main ingredients are mixed; then nano-titanium dioxide, modified brucite fiber, hydroxyethyl cellulose and sodium lignosulfonate are added to the mixed main ingredients in an amount of ethylene-carbon monoxide 33% of the copolymer weight is made ...

Embodiment 2

[0026] A method for preparing a high-temperature-resistant degradable plastic bowl, comprising the following steps:

[0027]Ethylene-carbon monoxide copolymer, polylactic acid, polycarbonate and starch resin are placed in the reactor, consisting of the following parts by weight: ethylene-carbon monoxide copolymer 58, polylactic acid 44, polycarbonate 37, starch resin 23, with 2.5 ℃ / min Stir continuously and heat until completely melted, keep stirring for 35 minutes, and fully stir to make the raw materials fully branched, improve the strength and heat resistance of the plastic bowl, avoid softening and deformation after heating, and the added raw materials are safe and healthy. It can be completely degraded without any residue, and the main ingredients are mixed; then nano-titanium dioxide, modified brucite fiber, hydroxyethyl cellulose and sodium lignosulfonate are added to the mixed main ingredients in an amount of ethylene-carbon monoxide 34% of the copolymer weight is made...

Embodiment 3

[0029] A method for preparing a high-temperature-resistant degradable plastic bowl, comprising the following steps:

[0030] Ethylene-carbon monoxide copolymer, polylactic acid, polycarbonate and starch resin are placed in the reactor, consisting of the following parts by weight: ethylene-carbon monoxide copolymer 59, polylactic acid 45, polycarbonate 38, starch resin 24, with 3 ℃ / min Stir continuously and heat until completely melted, keep stirring for 40 minutes, and fully stir to make the raw materials fully branched, improve the strength and heat resistance of the plastic bowl, avoid softening and deformation after heating, and the added raw materials are safe and healthy. It can be completely degraded without any residue, and the main ingredients are mixed; then nano-titanium dioxide, modified brucite fiber, hydroxyethyl cellulose and sodium lignosulfonate are added to the mixed main ingredients in an amount of ethylene-carbon monoxide 35% of the copolymer weight is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com