Method for recycling copper minerals from copper and sulfur separating tailings

A copper-sulfur separation and copper recovery technology, applied in the direction of solid separation, cyclone device, etc., can solve the problems of poor buoyancy, high fine mud content, high sulfur-copper ratio, etc., to reduce entrainment, reduce adverse effects, and improve foam status effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

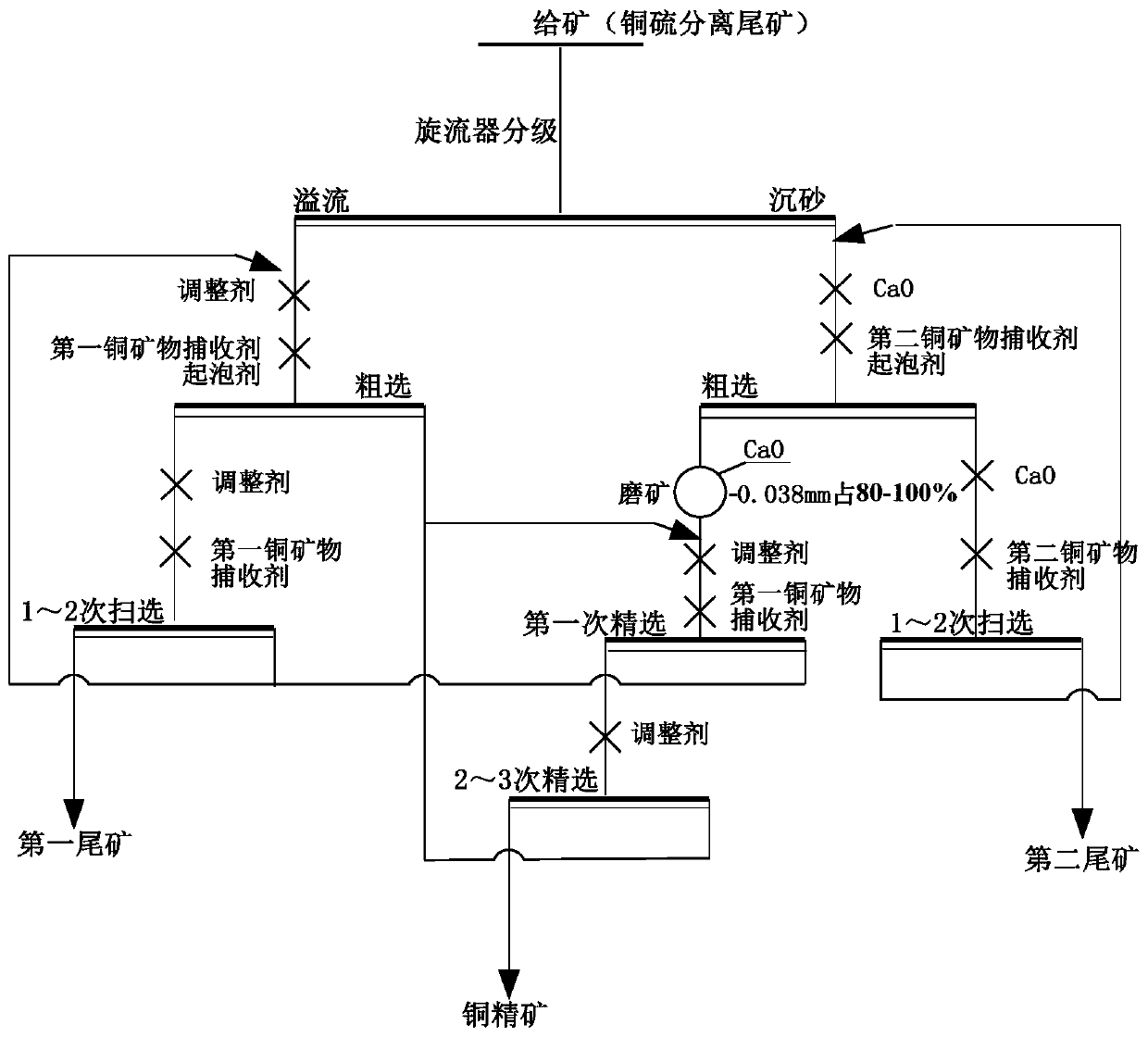

[0036] (1) In the classification operation, the copper-sulfur separation tailings are classified by the cyclone, and the obtained grit minerals are -0.043mm, accounting for 50% to 70%, and the minerals in the overflow are -0.038mm. 80% to 100%, so that the fine-grained copper minerals are separated from the coarse-grained copper-bearing associations. The main useful minerals in the sediment are coarse-grained copper-containing associations, and the main useful minerals in the overflow are fine-grained copper. Minerals, minerals in sedimentation and overflow are all under narrow particle size conditions, which can facilitate the subsequent targeted flotation treatment of sedimentation and overflow, and effectively solve the problem of copper-sulfur separation tailings under wide particle size conditions. The flotation recovery rate of copper minerals in mines is not high. In practical application, the ore feeding pressure of the cyclone classification is preferably 0.08-0.12 MP...

Embodiment 1

[0052] A veinlet disseminated copper-sulfur ore, the main metal minerals in the raw ore are chalcopyrite, pyrite, and a small amount of chalcocite, and the main gangue minerals are quartz, feldspar, dolomite, chlorite, pyroxene Wait. The raw ore undergoes "copper-sulfur mixed separation-coarse concentrate regrinding-copper-sulfur separation" operation, and the obtained copper-sulfur separation tailings contain 0.17% copper and 34.54% sulfur. The copper minerals in the copper-sulfur separation tailings are mainly brass The pyrite minerals are mainly pyrite, and the particle size of copper-sulfur separation tailings is -0.043mm, accounting for 72%.

[0053] A method for recovering copper minerals from copper-sulfur separation tailings, used for beneficiation of copper minerals in the copper-sulfur separation tailings, specifically may include the following steps:

[0054] Step 1. Classify the copper-sulfur separation tailings by cyclone to obtain overflow and grit; the obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com