Process method beneficial to improving recovery rate of lead and silver in lead concentrate

A technology of process method and recovery rate, which is applied in the direction of solid separation, cyclone device, grain treatment, etc., can solve the problems of prolonging flotation time and low flotation recovery rate, so as to prolong flotation time, improve overall recovery rate, The effect of widely promoting the prospect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is described further below according to accompanying drawing:

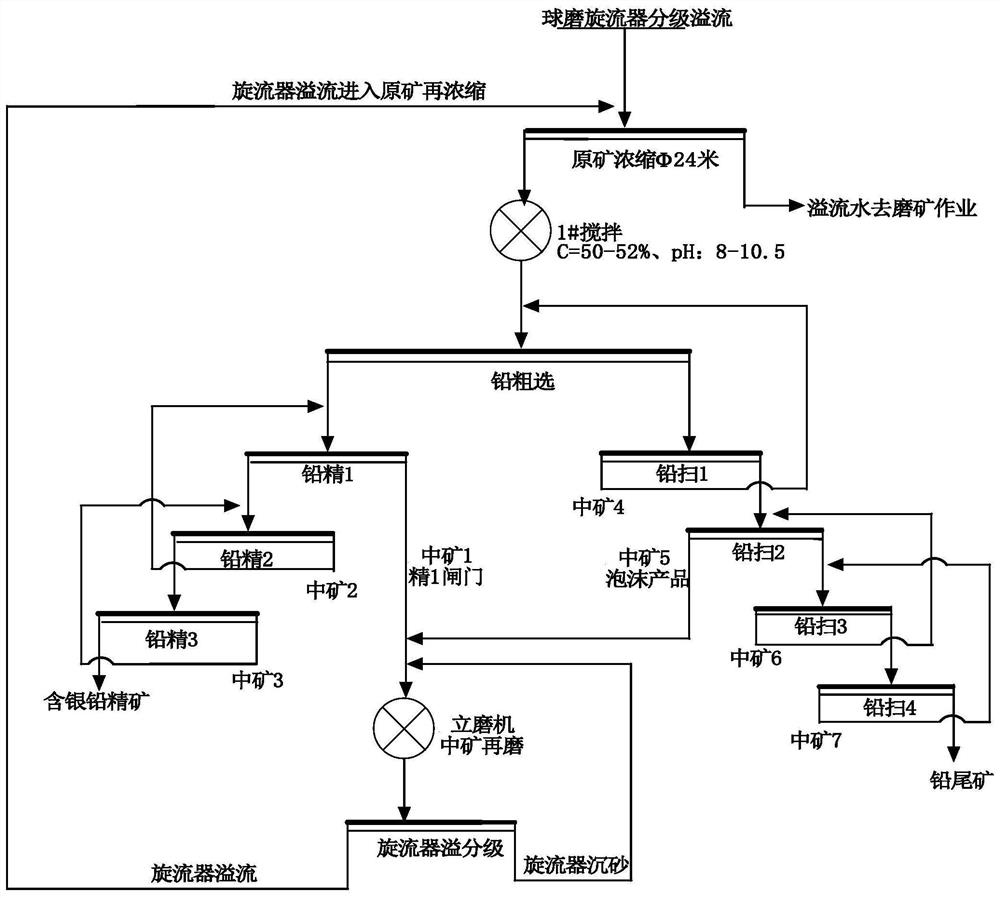

[0021] The present embodiment provides a kind of technological method that is conducive to improving the recovery rate of lead and silver in the lead concentrate, and concrete process is as follows figure 2 shown, including the following steps:

[0022] Step (1), after the raw ore is ground and classified by the ball mill, the cyclone is classified and overflowed to obtain the raw ore classified overflow product.

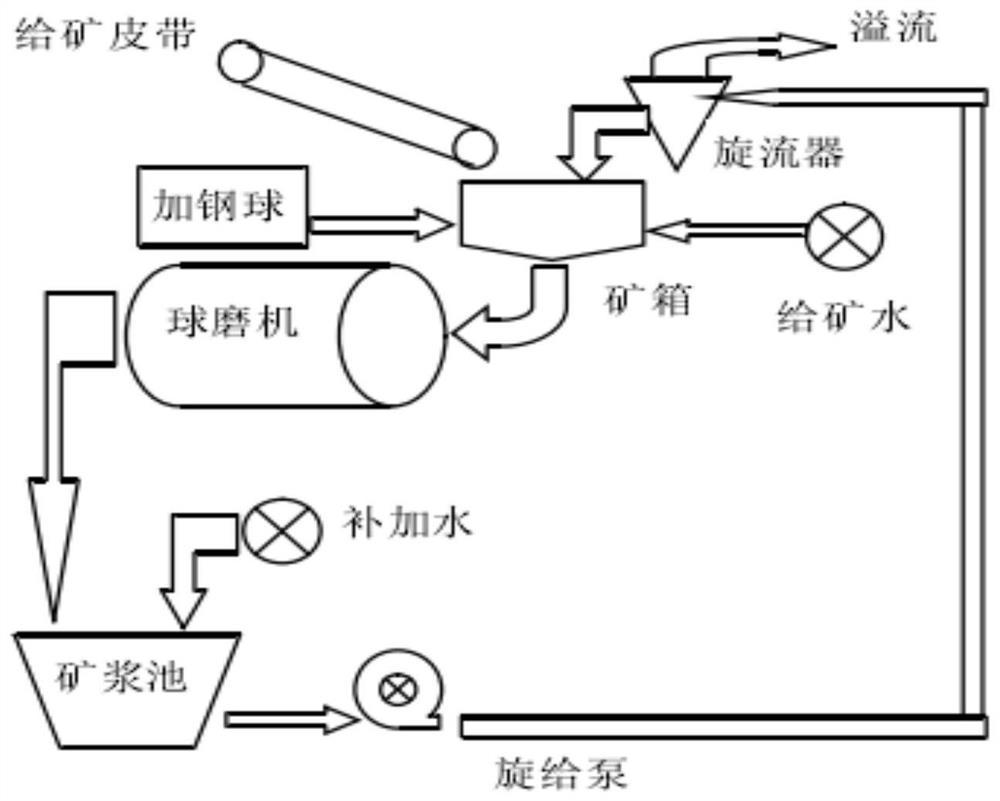

[0023] The grinding and grading process of the present embodiment is as figure 1 As shown, the ore is conveyed to the ore box by the ore belt, the ore is mixed with the ore and then sent to the ball mill, the ball mill grinds the ore to the slurry pool, and water is added in the slurry pool, and it is transported to the cyclone through the rotary feed pump, and the cyclone Underflow to the ore box. In this example, the belt feed, ball mill disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com