Harmless three-phase separation method and device for swill

A three-phase separation and swill technology, applied in chemical instruments and methods, solid separation, sieves, etc., can solve the problems of difficulty in controlling the moisture content of the discharge material, clogging of large particles in the swill, etc., to avoid clogging, control the moisture content, The effect of not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

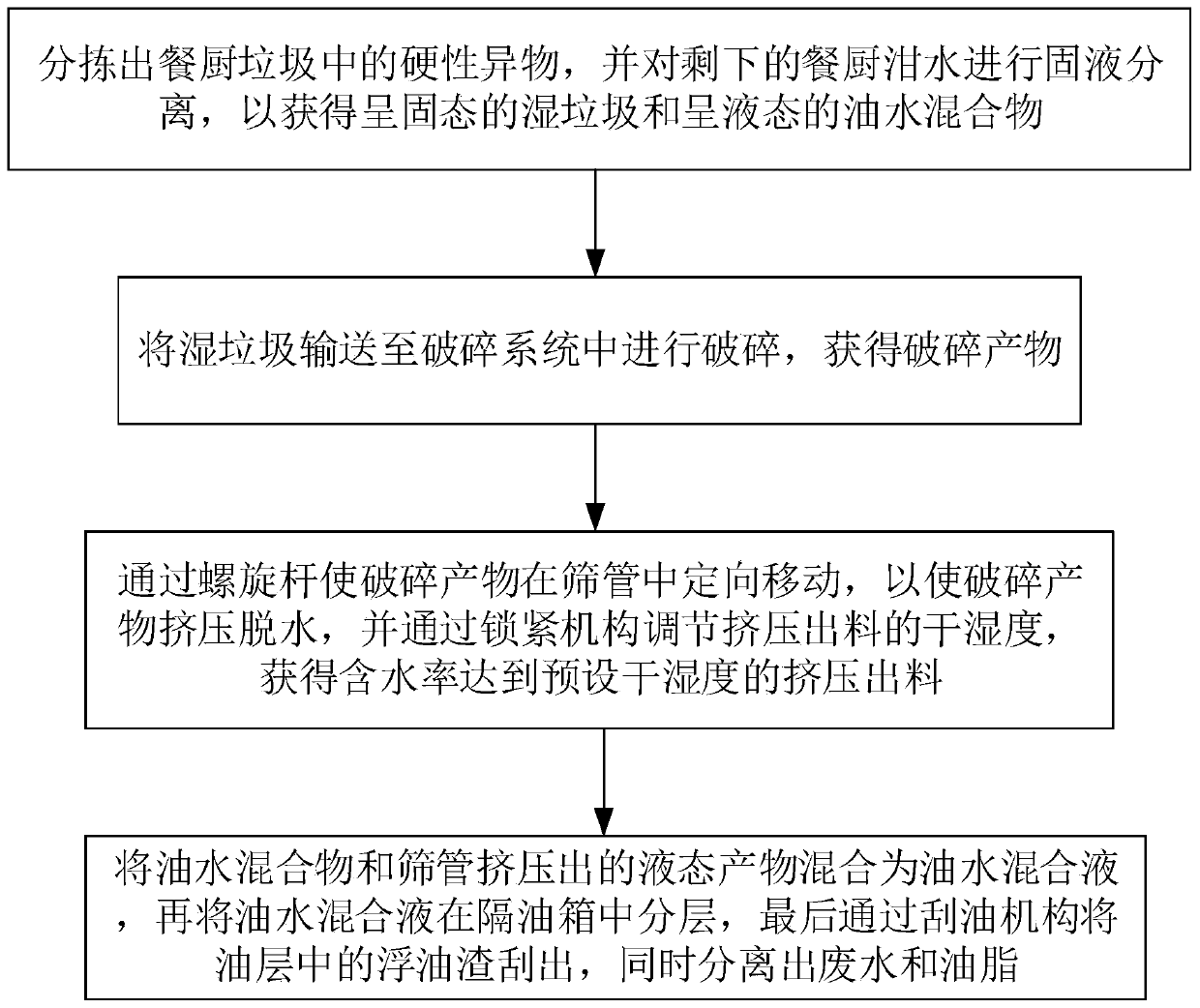

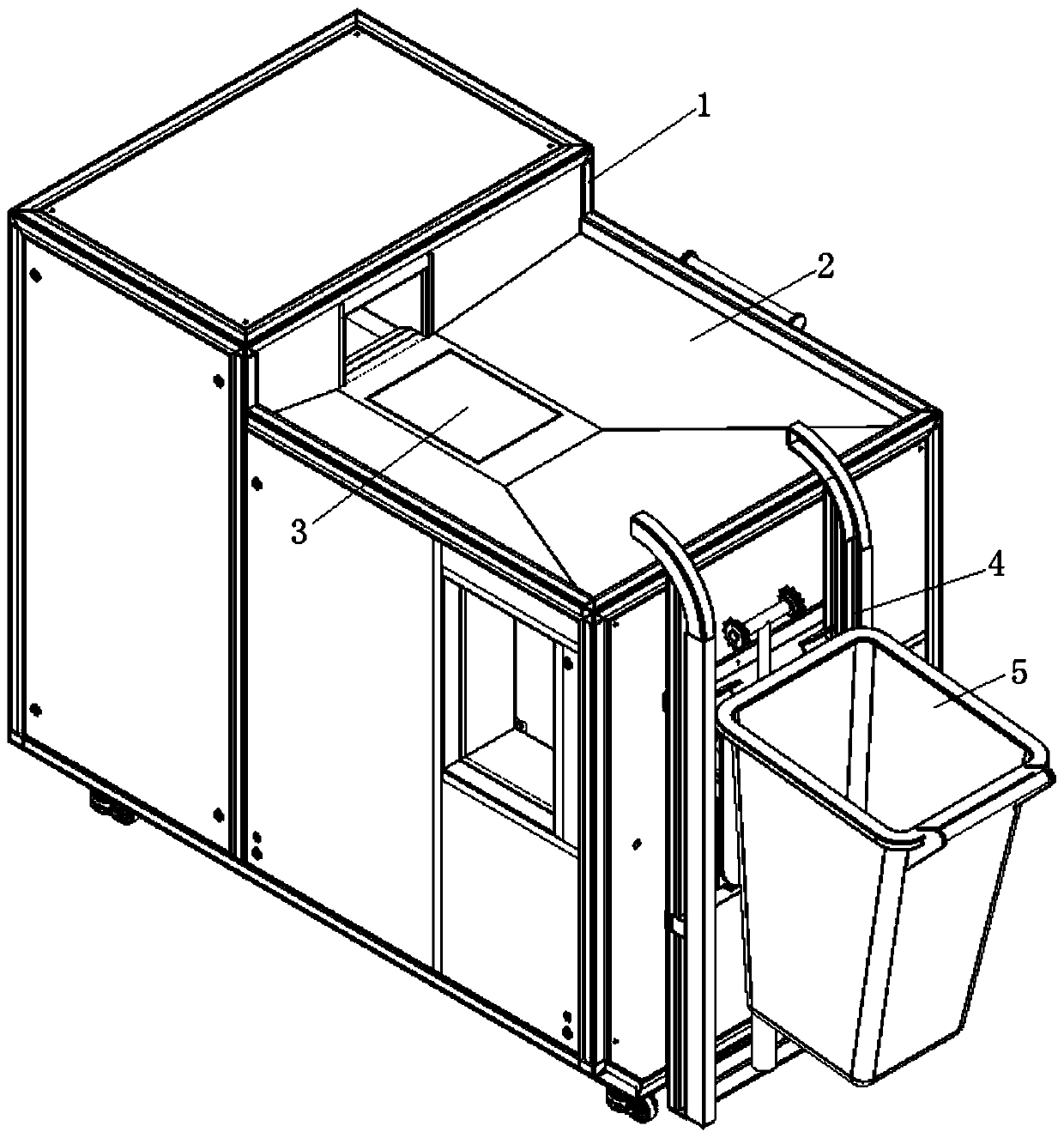

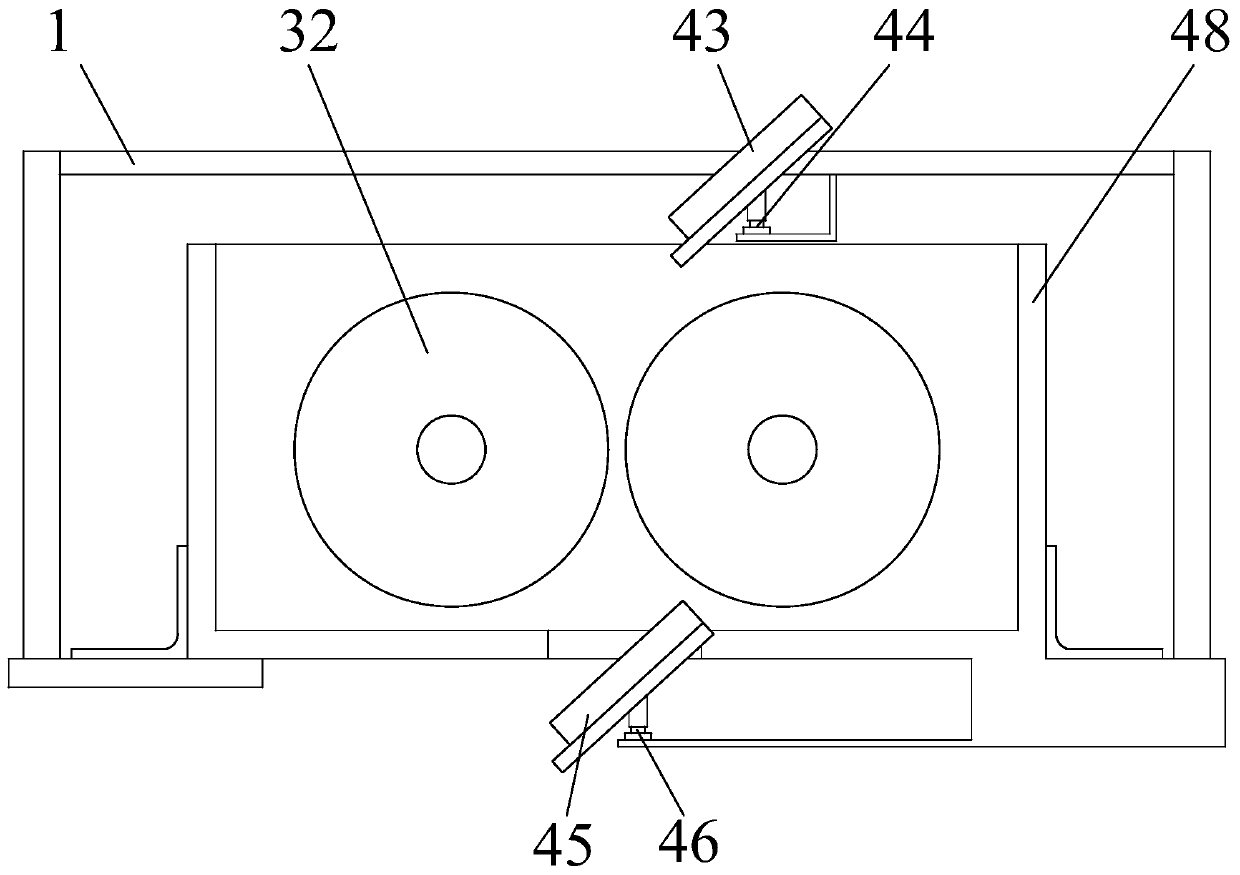

[0067] see figure 1 as well as figure 2 , this embodiment provides a three-phase separation method for harmless swill, which can be used by using a three-phase separation device for swill. Wherein, the swill three-phase separation device includes a frame body 1, a sorting system, a crushing system, an extrusion system, an oil-water separation system, and a feeding system. In this embodiment, the three-phase separation method for harmless swill includes the following steps.

[0068] Step 1. Sorting out the hard foreign matter in the kitchen waste, and performing solid-liquid separation on the remaining kitchen swill to obtain solid wet garbage and liquid oil-water mixture. In this embodiment, a sorting system is used for sorting. Among them, the sorting system is used to sort and separate food waste to remove hard foreign matter, and obtain solid wet waste and liquid oil-water mixture. Wherein, the sorting system includes a sorting platform 2 and a net plate 3 . The sorti...

Embodiment 2

[0105] This embodiment provides a three-phase separation method for harmless swill, which adds the step of scraping out scum on the basis of embodiment 1. Wherein, the method for scraping out oil scum comprises the following steps:

[0106] (I) Detect the liquid level of the liquid in the oil scraping mechanism;

[0107] (II) judging whether the liquid level height is greater than a preset height one;

[0108] (Ⅲ) When the height of the liquid level is greater than the preset height 1, the oil scraping mechanism is driven to scrape the liquid;

[0109] (Ⅳ) judging whether the liquid level height is greater than a preset height two;

[0110] (Ⅴ) When the liquid level is higher than the liquid level two, stop conveying the oil-water mixture to the receiving space;

[0111] (Ⅵ) Calculate the height change value of the liquid level within a preset time;

[0112] (VII) According to the change value of the liquid level, adjust the power of the oil scraping mechanism according to...

Embodiment 3

[0114] This embodiment provides a three-phase separation device for harmless swill, which applies the three-phase separation method for harmless swill in embodiment 1 or embodiment 2, and includes a feeding module, a sorting module, a crushing module, Extrusion module and oil-water separation module. The feeding module is used to lift and feed the food waste to be separated into three phases in the garbage bin 5 through the hoist 4 . The sorting module is used to receive the food waste in the garbage bin 5, sort out the hard foreign matter in the food waste, and perform solid-liquid separation on the remaining food swill to obtain solid wet waste and liquid waste. Oil-water mixture. The crushing module is used to convey the wet waste to a crushing system for crushing to obtain crushed products. The extrusion module is used to make the crushed product move directionally in the screen tube 70 through the screw rod 54, so as to extrude and dehydrate the crushed product, and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com