Preparation method of sintered rare-earth iron-boron permanent magnet material for regulating and controlling grain boundary

A technology of rare earth iron boron and permanent magnet materials, which is applied in the direction of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problem of reducing remanence, grain boundary composition or tissue influence and limited regulation, and magnet coercive force Solve problems such as limited improvement of force and strength, achieve the effect of increasing adsorption strength, eliminating the possibility of oxidation, and reducing the distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

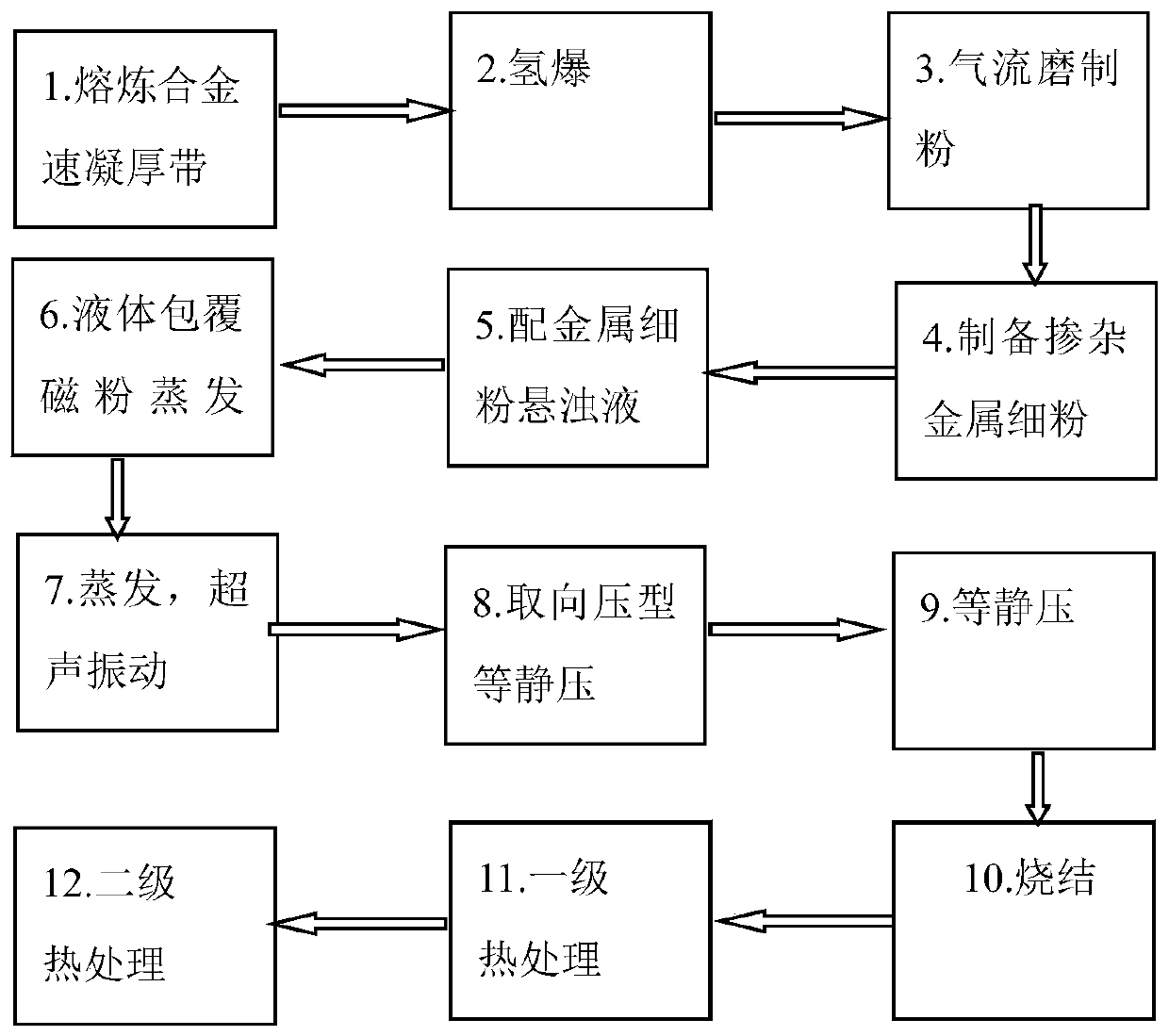

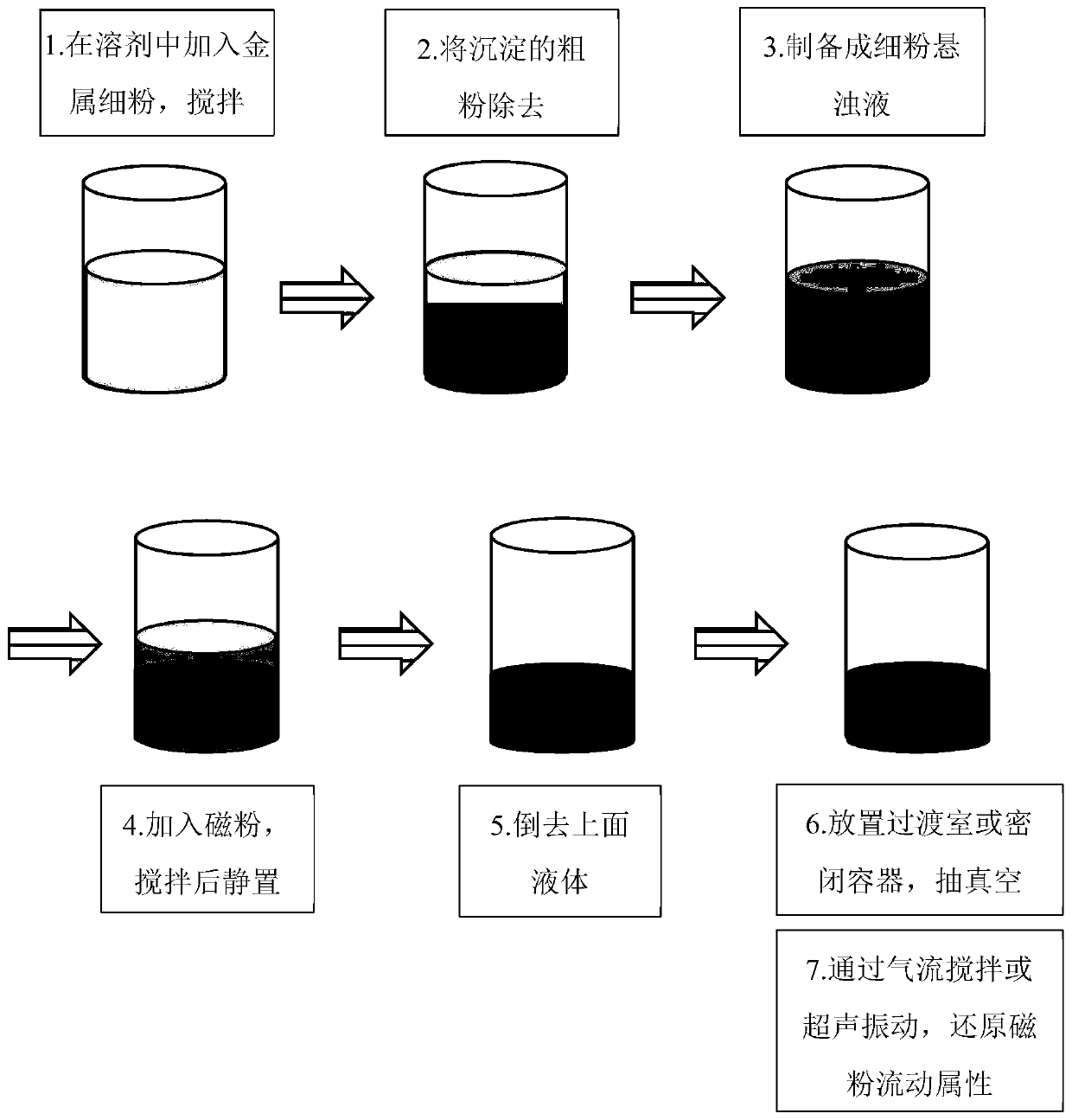

Method used

Image

Examples

Embodiment 1

[0042] Change the nominal component to Nd 18.5 Pr 5.5 Gd 2 Ce 5 Nb 0.1 Zr 0.1 Fe 67.8 B 1 After hydrogen explosion and jet milling process, the alloy thick belt is made into magnetic powder with an average particle size of about 3 microns; Al nano-powder is prepared by high-voltage arc evaporation-condensation technology; nano-suspension is prepared using absolute ethanol, and the magnetic powder is added to the suspension Mix the liquid and stir, pour out the excess liquid, vacuum and air dry, and use an ultrasonic vibrator to process the air-dried powder to restore its flow properties. The doped Al concentration is 0.49wt%, and the sintering and heat treatment processes are respectively: temperature 1050°C, time 2.5hr; temperature 900°C, time 2hr; temperature 500°C, time 2hr. The product prepared in this example is called sample 1.

Embodiment 2

[0044] The doping process is the same as in Example 1, the doped Al concentration is 0.86 wt%, and the sintering and heat treatment processes are respectively: temperature 1050°C, time 2.5hr; temperature 900°C, time 2hr; temperature 500°C, time 2hr. The product prepared in this example is called sample 2.

Embodiment 3

[0046] The doping process is the same as in Example 1, the doped Al concentration is 1.15 wt%, and the sintering and heat treatment processes are respectively: temperature 1050°C, time 2.5hr; temperature 900°C, time 2hr; temperature 500°C, time 2hr. The product prepared in this example is called sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com