Double-layer foil winding machine for preparing superconducting wire

A technology of superconducting wire rod and foil winding machine, which is applied to superconducting devices, superconducting/high-conducting conductors, cables/conductors manufacturing and other directions, which can solve the problem that Nb foil is prone to springback, tower-shaped section, and declination. Accumulation and other problems, to achieve the effect of avoiding springback characteristics, high density, and simplifying the clamping structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

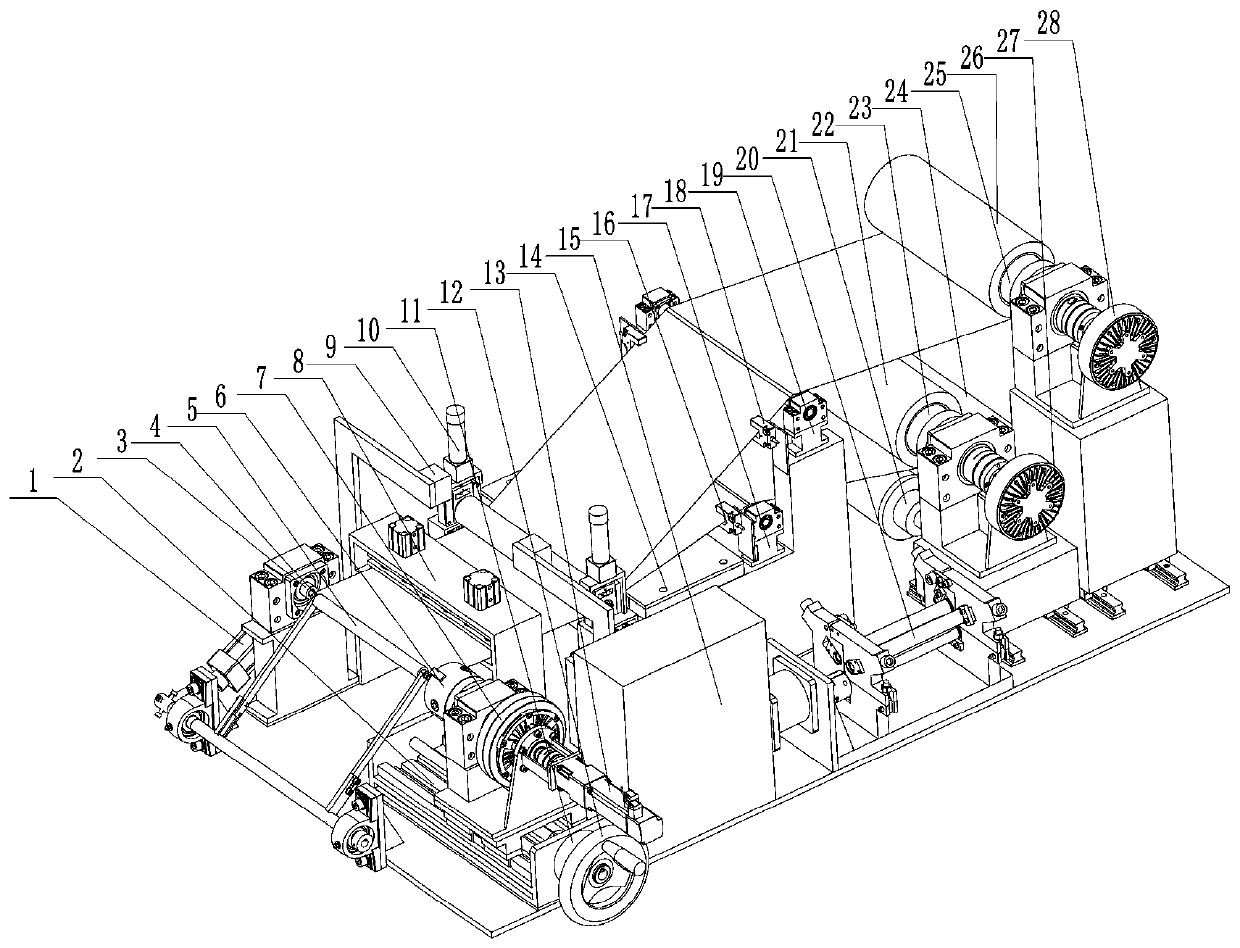

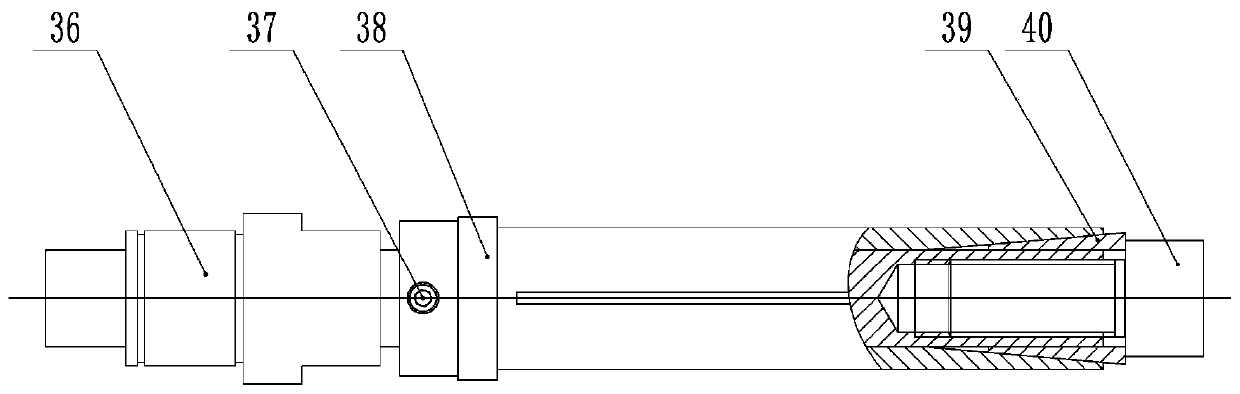

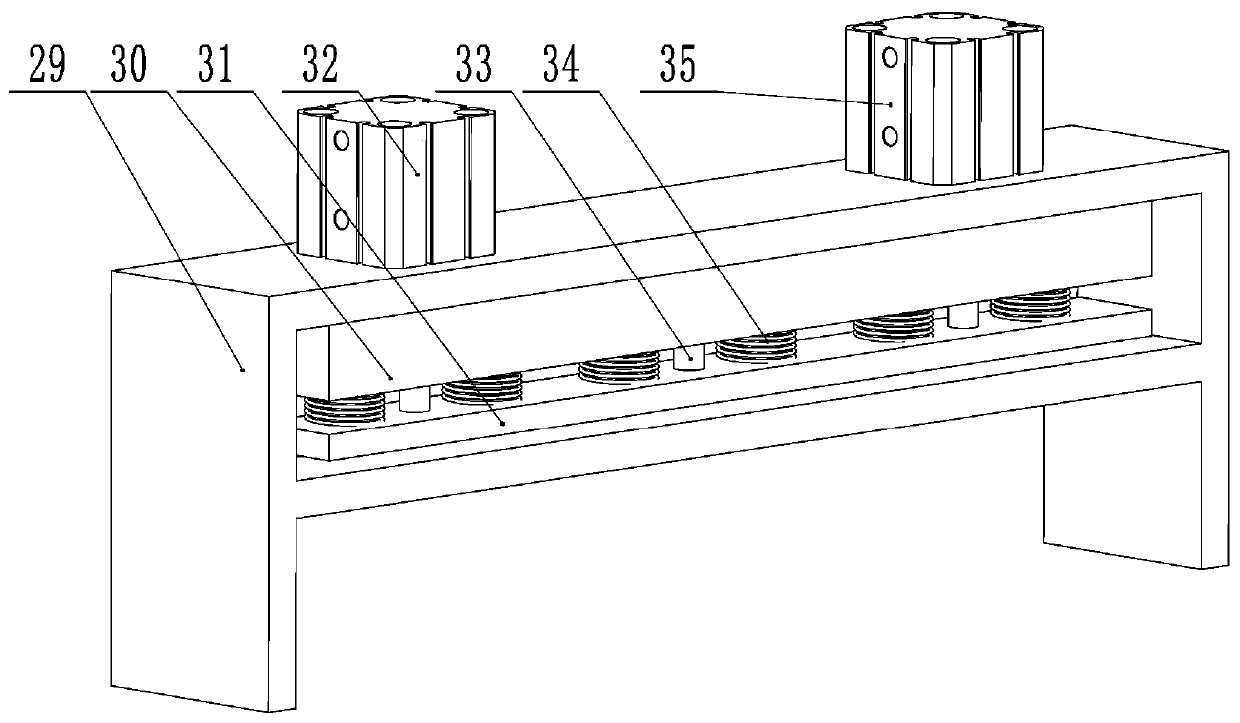

[0031] combine Figure 1-4As shown, the present invention provides a double-layer foil winding machine for the preparation of superconducting wires, including a machine body, the machine body includes a double discharging mechanism located at the rear end of the machine body, and a material receiving mechanism located at the front end of the machine body. The double-layer foil rolls placed by the discharging mechanism are connected to the corresponding brakes and the complete machine control system 15 through their respective tension detection units; the front of the tension detection unit is provided with a double correction system, and the double correction system is connected to the complete machine. The control system 15 is connected, and is connected with the respective corresponding correction actuators; the front of the double correction system is provided with a clamping mechanism 10, and the front end of the clamping mechanism 10 is equipped with a straightening mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com