Gas atmosphere controllable ablation testing device and method for ceramic matrix composite material

A composite material and testing device technology, applied in the investigation stage/state change, etc., can solve the problems of gas atmosphere monitoring and adjustment neglect, and achieve the effect of reducing on-site operations, reducing operational risks, and improving acquisition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

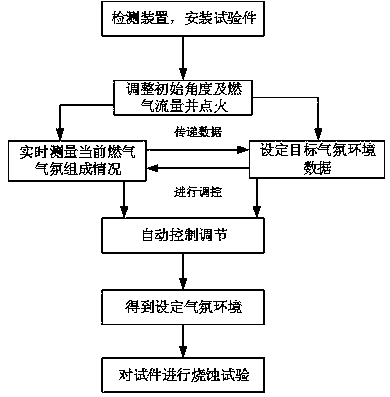

Method used

Image

Examples

Embodiment Construction

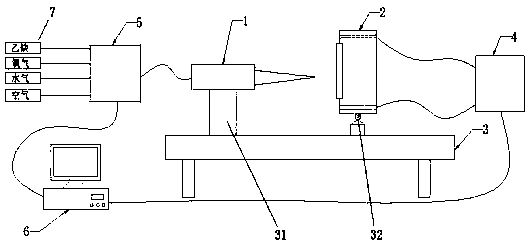

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029]A ceramic matrix composite material ablation test device with controllable gas atmosphere in this embodiment includes an ablation platform support 3, a high-speed flame spray gun 1, a test specimen clamping module 2, an integrated gas supply module 7, and a high-speed flame spray gun 1 and the test specimen clamping module 2 are installed on the ablation platform support 3, the ablation platform support 3 can drive the high-speed flame spray gun 1 or / and the test specimen clamping module 2 can slide and turn over on the ablation platform support 3, The test specimen clamping module 2 is used to clamp the ceramic matrix composite material specimen, the integrated gas supply module 7 is connected with the high-speed flame spray gun 1, and provides gas for the high-speed flame spray gun 1, and the nozzle of the high-speed flame spray gun 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com