A kind of high-performance biodegradable zn-cu-li-x alloy and its preparation and application method

A zn-cu-li-x, high-performance technology, used in the design and preparation of biodegradable medical materials, can solve the problems of lack of supply and addition of Li, and achieve wide application prospects, easy processing and forming, and low alloy cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation and performance test of biodegradable Zn-Cu-Li-X quaternary alloy.

[0037] The mass percentage of each chemical element in the biodegradable Zn-Cu-Li-X quaternary alloy is shown in Table 1-1, and the balance is Zn. The alloy preparation process is vacuum induction smelting→homogenizing heat treatment→preheating→hot rolling or extrusion. The vacuum induction smelting uses high-purity block Zn, Zn-Cu intermediate alloy, high-purity block Li and materials containing X elements as raw materials, and the ingredients are added to the crucible according to the mass percentage, and the vacuum is pumped to 10Pa and filled with argon protection. Turn on the power supply, gradually increase the power to 5KW, and after 5 minutes at 600°C, pour it into the graphite mold.

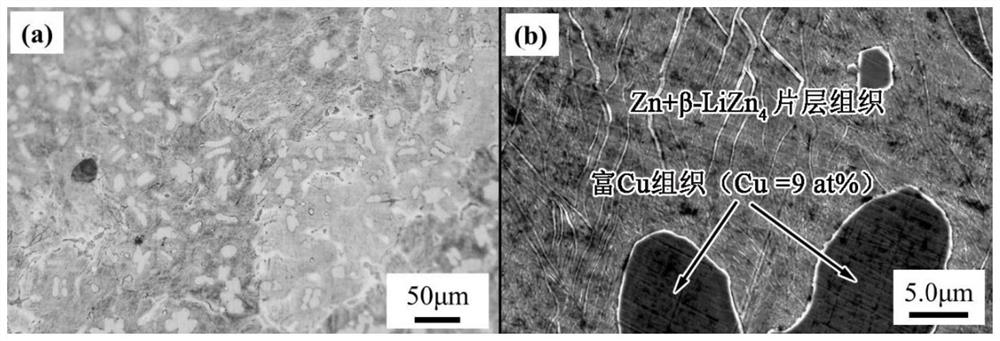

[0038] Homogenization treatment: place the alloy ingot in a box-type heating and sintering furnace KSL-1400X, raise the temperature to 220°C at a rate of 2°C / min, and keep it for 1 hour; t...

Embodiment 2

[0049] Example 2: Preparation and performance test of biodegradable Zn-Cu-Li-X quinary alloy.

[0050] The mass percentage of each chemical element in the biodegradable Zn-Cu-Li-X quinary alloy is shown in Table 2-1, and the balance is Zn. The preparation process of the degradable quinary alloy is vacuum induction smelting→homogenizing heat treatment→preheating→hot rolling or extrusion. Melting and homogenization heat treatment were carried out according to the method provided in Example 1. After homogenization heat treatment, the microstructure of the Zn-Cu-Li-X quinary alloy is composed of fine and dense Zn+β-LiZn 4 Sheets, Cu-rich matrix and its nano-scale precipitates containing X elements. Samples were cut from the obtained profiles to test in vitro corrosion, cytotoxicity and tensile mechanical properties at room temperature. The preparation and testing methods of the above samples were carried out according to the method provided in Example 1.

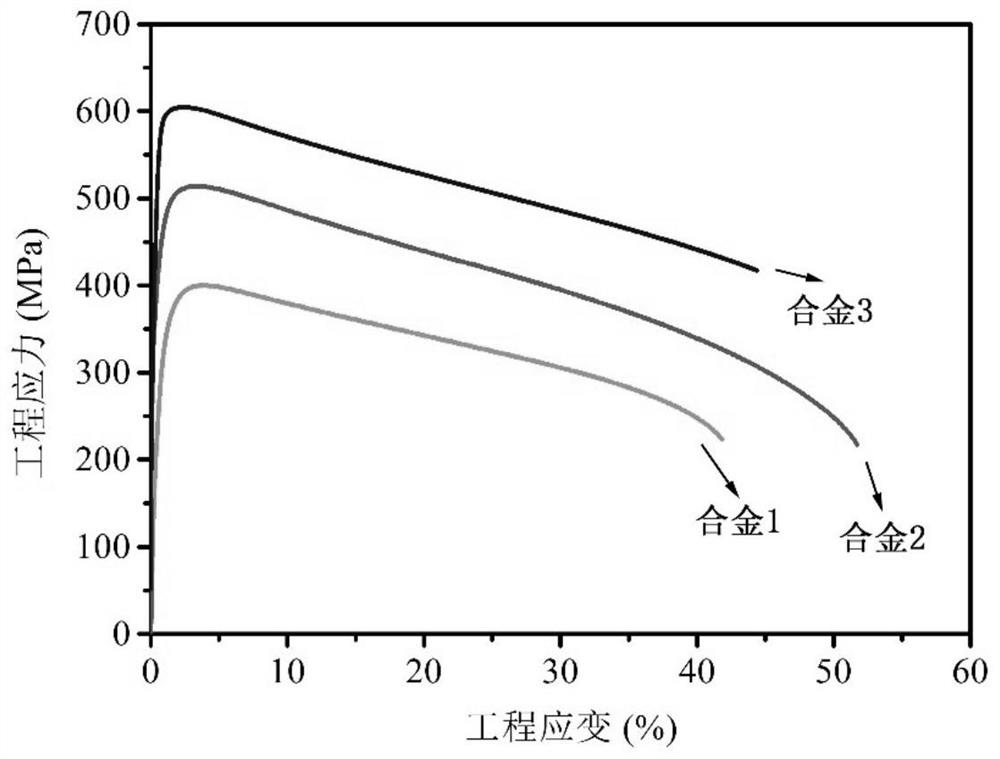

[0051] It is measure...

Embodiment 3

[0056] Example 3: Preparation and performance test of biodegradable Zn-Cu-Li-X six-element alloy.

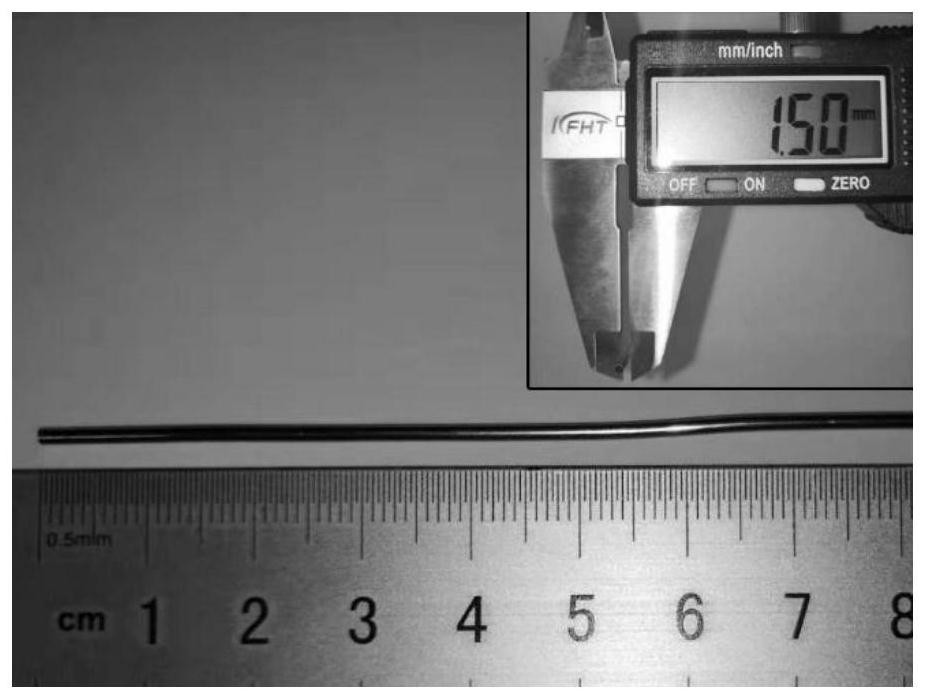

[0057] The mass percentage of each chemical element in the biodegradable Zn-Cu-Li-X six-element alloy is shown in Table 3-1, and the balance is Zn. The preparation process of the degradable six-element alloy is vacuum induction melting→homogenizing heat treatment→preheating→hot rolling or extrusion or drawing. Melting and homogenization heat treatment were carried out according to the method provided in Example 1. After homogenization heat treatment, the microstructure of the Zn-Cu-Li-X six-element alloy is composed of fine and dense Zn+β-LiZn 4 Sheets, Cu-rich matrix and its nano-scale precipitates containing X elements. Samples were cut from the obtained profiles to test in vitro corrosion, cytotoxicity and tensile mechanical properties at room temperature. The preparation and testing methods of the above samples were carried out according to the method provided in Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com