Preparation method of high-strength and wear-resistant copper alloy pipe

A wear-resistant copper and pipe technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of long process, high complexity, complex transformation process, etc., and achieve the effect of improving strength and increasing dispersion strengthening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

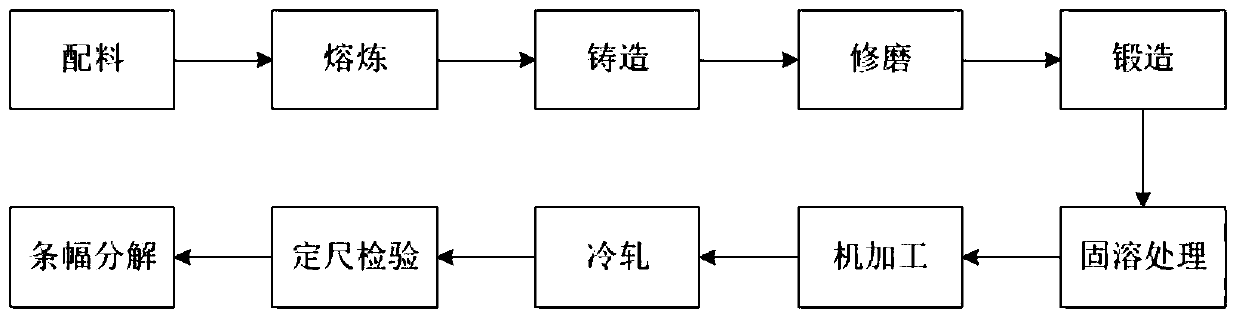

Method used

Image

Examples

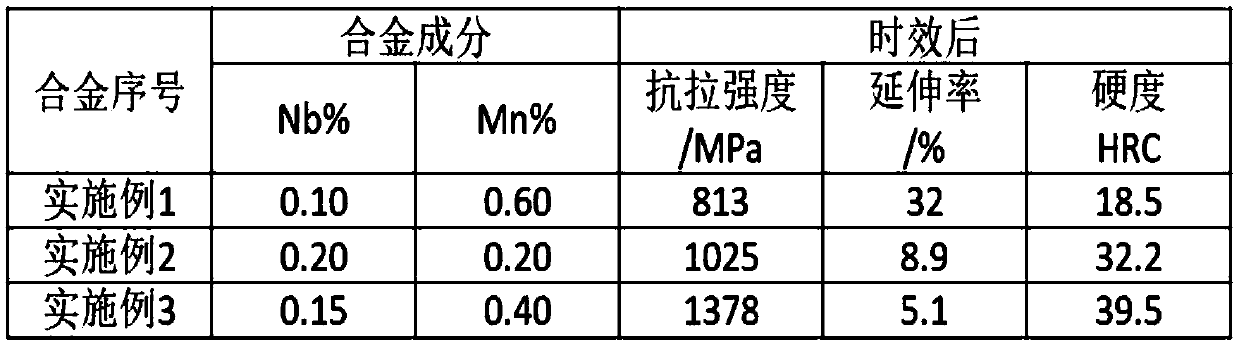

Embodiment 1

[0033] In this embodiment, a method for producing high-strength copper alloy large-scale ingots by vacuum smelting is obtained by the following method:

[0034] (1) Ingredients: the raw materials used and their proportioning ratio are shown in Table 1,

[0035] Table 1

[0036] Element Grade standard mass percentage Electrolytic copper Cu99.95 GB / T467-2010 76.30% Electrolytic nickel Ni99.95 GB / T6515-2010 14.00% Tin ingots Sn99.95 GB / T 728-2010 9.00% Niobium bar Nb1 GB / T 14842-2010 0.10% Electrolytic manganese JMn98 GB / T 2774-2010 0.60%

[0037] (2) Melting: Use a vacuum induction furnace for smelting. After the alloy is completely melted, refine it for 10 minutes, reduce the power, and fill it with argon to 0.8×10 5 Pa, add manganese alloy in the upper silo, adjust the power to control the temperature of the molten metal;

[0038] (3) Casting: The molten metal casting temperature is 1250°C, using cast iron...

Embodiment 2

[0048] In this embodiment, a method for producing high-strength copper alloy large-scale ingots by vacuum smelting is obtained by the following method:

[0049] (1) Ingredients: the raw materials used and their proportioning ratio are shown in Table 2,

[0050] Table 2

[0051] Element Grade standard mass percentage Electrolytic copper Cu99.95 GB / T467-2010 76.60% Electrolytic nickel Ni99.95 GB / T6515-2010 15.00% Tin ingots Sn99.95 GB / T 728-2010 8.00% Niobium bar Nb1 GB / T14842-2007 0.20% Electrolytic manganese JMn98 GB / T 2774-2008 0.20%

[0052] (2) Melting: Use a vacuum induction furnace for smelting. After the alloy is completely melted, refine it for 15 minutes, reduce the power, and fill it with argon to 0.85×10 5 Pa, add manganese alloy in the upper silo, adjust the power to control the temperature of the molten metal;

[0053](3) Casting: The molten metal casting temperature is 1270°C, using cast iron ...

Embodiment 3

[0063] In this embodiment, a method for producing high-strength copper alloy large-scale ingots by vacuum smelting is obtained by the following method:

[0064] (1) Ingredients: the raw materials used and their proportioning ratio are shown in Table 3,

[0065] table 3

[0066] Element Grade standard mass percentage Electrolytic copper Cu99.95 GB / T467-2010 76.45% Electrolytic nickel Ni99.96 GB / T6515-2010 16% Tin ingots Sn99.97 GB / T 728-2010 7% Niobium bar Nb1 GB / T14842-2007 0.15% Electrolytic manganese JMn98 GB / T 2774-2008 0.40%

[0067] (2) Melting: Use a vacuum induction furnace for smelting. After the alloy is completely melted, refine it for 20 minutes, reduce the power, and fill it with argon to 0.95×10 5 Pa, add manganese alloy in the upper silo, adjust the power to control the temperature of the molten metal;

[0068] (3) Casting: The molten metal casting temperature is 1280°C, using cast iron molds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com