Granular concentrated detergent composition

A detergent and composition technology, applied in the field of granular concentrated detergent compositions, can solve the problems of large skin irritation, narrow selection of surfactants, large damage to fabric fibers, etc., and achieve excellent fluidity and pourability, Solving the effect of particle formability and good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

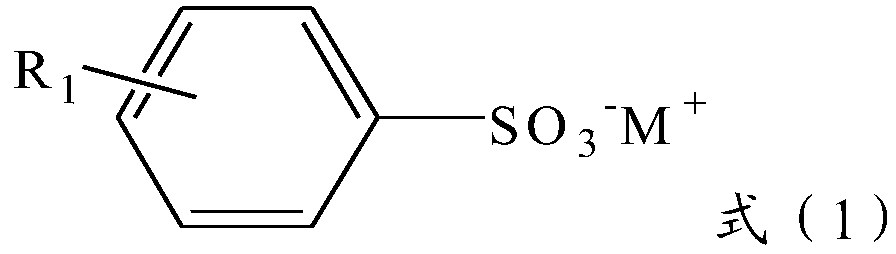

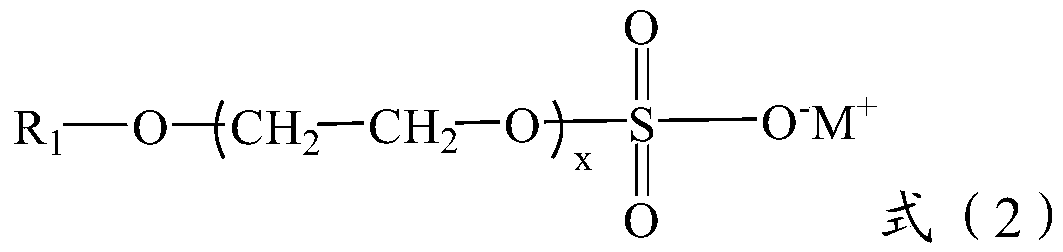

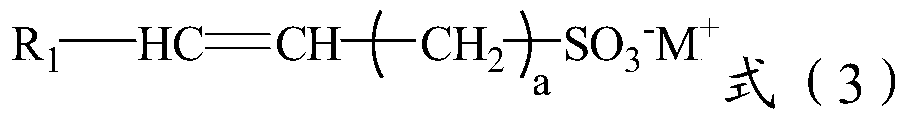

Method used

Image

Examples

preparation example Construction

[0080] The preparation method of the granular concentrated detergent composition provided by the embodiments of the present invention comprises the following steps:

[0081] 1) According to the proportion, put the liquid raw materials into the mixing pot, add the powder raw materials and additives in turn, and finally add the hydrophilic silica raw materials, stir and mix them, and then pass through the three-roll mill for further mixing;

[0082] 2) Through a rotary granulator or a screw extruder (the discharge mesh is preferably 0.5mm to 1.2mm);

[0083] 3) After extruding the particles, a small amount of hydrophilic silicon dioxide can also be added, and after being crushed by a crusher, detergent particles with better fluidity and particle uniformity can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com