Catalyst for olefin polymerization, and preparation method thereof, and catalyst composition for olefin polymerization, and applications thereof

A technology of olefin polymerization and catalyst, applied in the production of bulk chemicals, etc., can solve the problems of low fine powder content, low activity, high isotacticity of polymers, etc., achieve low fine powder content, reduce initial activity, and be difficult for activity decay Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0098] The second aspect of the present invention provides a method for preparing the catalyst of the present invention, characterized in that the method comprises the following steps:

[0099] 1) Under the protection of an inert gas, the metal magnesium, ethanol and 2-ethylhexanol are refluxed in the presence of a halogenating agent to prepare an alkoxymagnesium carrier;

[0100] 2) In the presence of an inert diluent, the alkoxymagnesium carrier, the electron donor compound and the titanium compound are subjected to a contact reaction, washed and dried with an inert solvent to obtain a catalyst solid component;

[0101] 3) mixing the catalyst solid component with an alkane solvent, adding an organoaluminum compound for the first treatment to obtain a catalyst precursor, and then passing through the olefin for the second treatment;

[0102] 4) washing the product obtained in step 3) with alkanes and / or aromatics, filtering and drying to obtain the catalyst;

[0103] Wherein,...

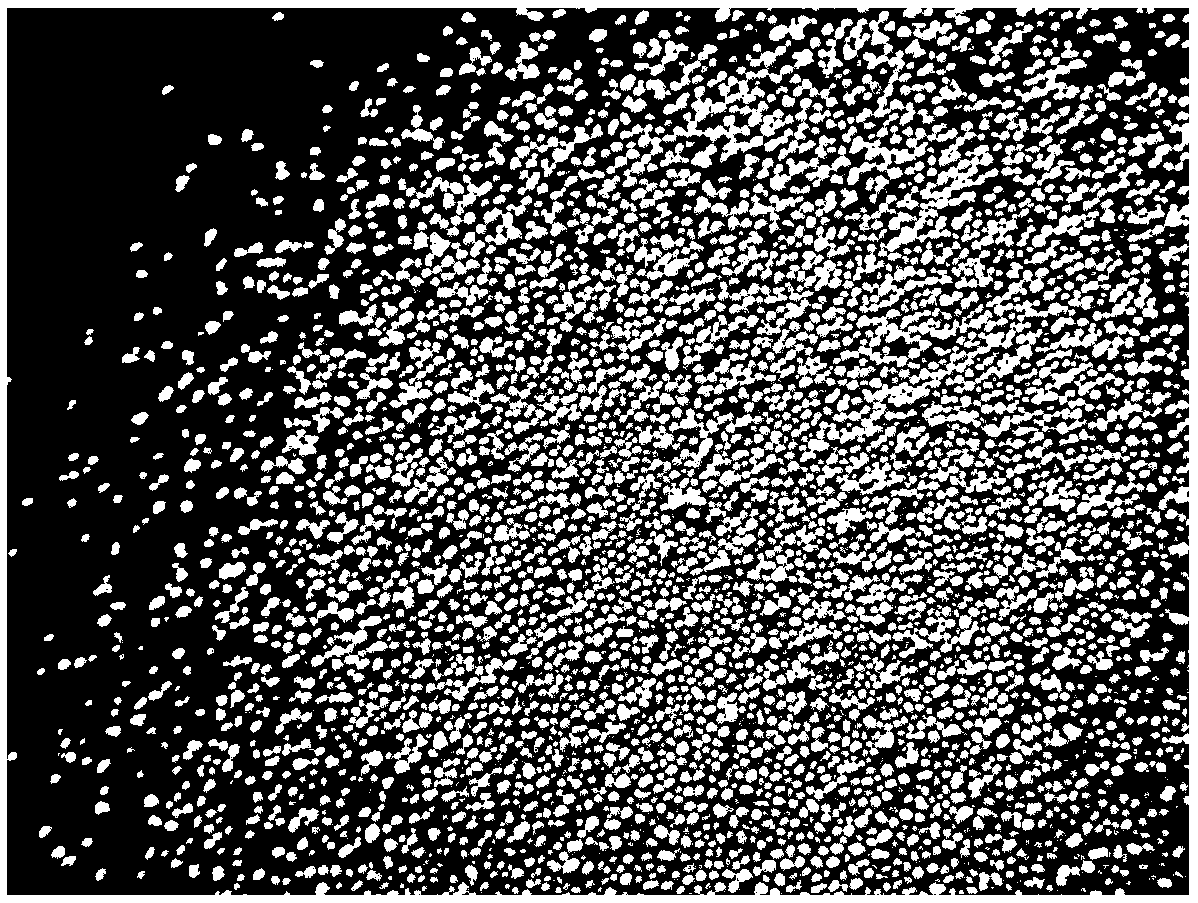

preparation example 1

[0201] After fully replacing the 16L pressure-resistant reactor with agitator with nitrogen, add 10L ethanol, 300mL 2-ethylhexanol, 11.2g iodine, 8g magnesium chloride and 640g magnesium powder into the reactor. While stirring, the temperature of the system was raised to 75°C for reflux reaction. After about 5 hours of reaction, no hydrogen gas was emitted from the system, and the reaction was stopped. Wash with 3L of ethanol, filter and dry to obtain alkoxymagnesium carrier A1. The D50 of the obtained alkoxymagnesium carrier was 30.2 μm, the SPAN value was 0.81, and the m value was 0.015.

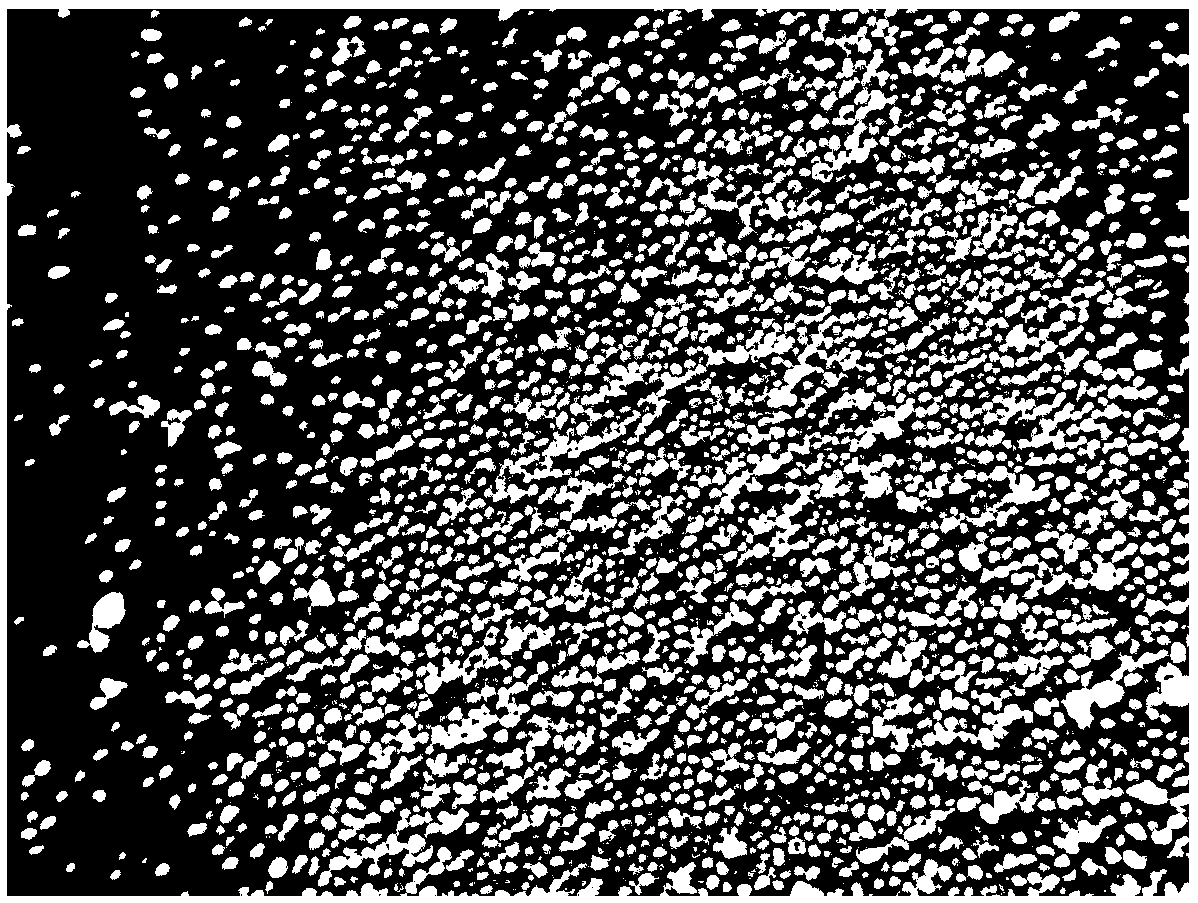

preparation example 2

[0203] After fully replacing the 16L pressure-resistant reactor with agitator with nitrogen, add 10L ethanol, 2500mL 2-ethylhexanol, 5g iodine, 40g magnesium chloride and 400g magnesium powder into the reactor. While stirring, the temperature of the system was raised to 62°C for reflux reaction. After about 8 hours of reaction, no hydrogen gas was released from the system, and the reaction was stopped. Wash with 3L of ethanol, filter and dry to obtain alkoxymagnesium carrier A2. The D50 of the obtained alkoxymagnesium support was 65.9 μm, the SPAN value was 0.65, and the m value was 0.19.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com