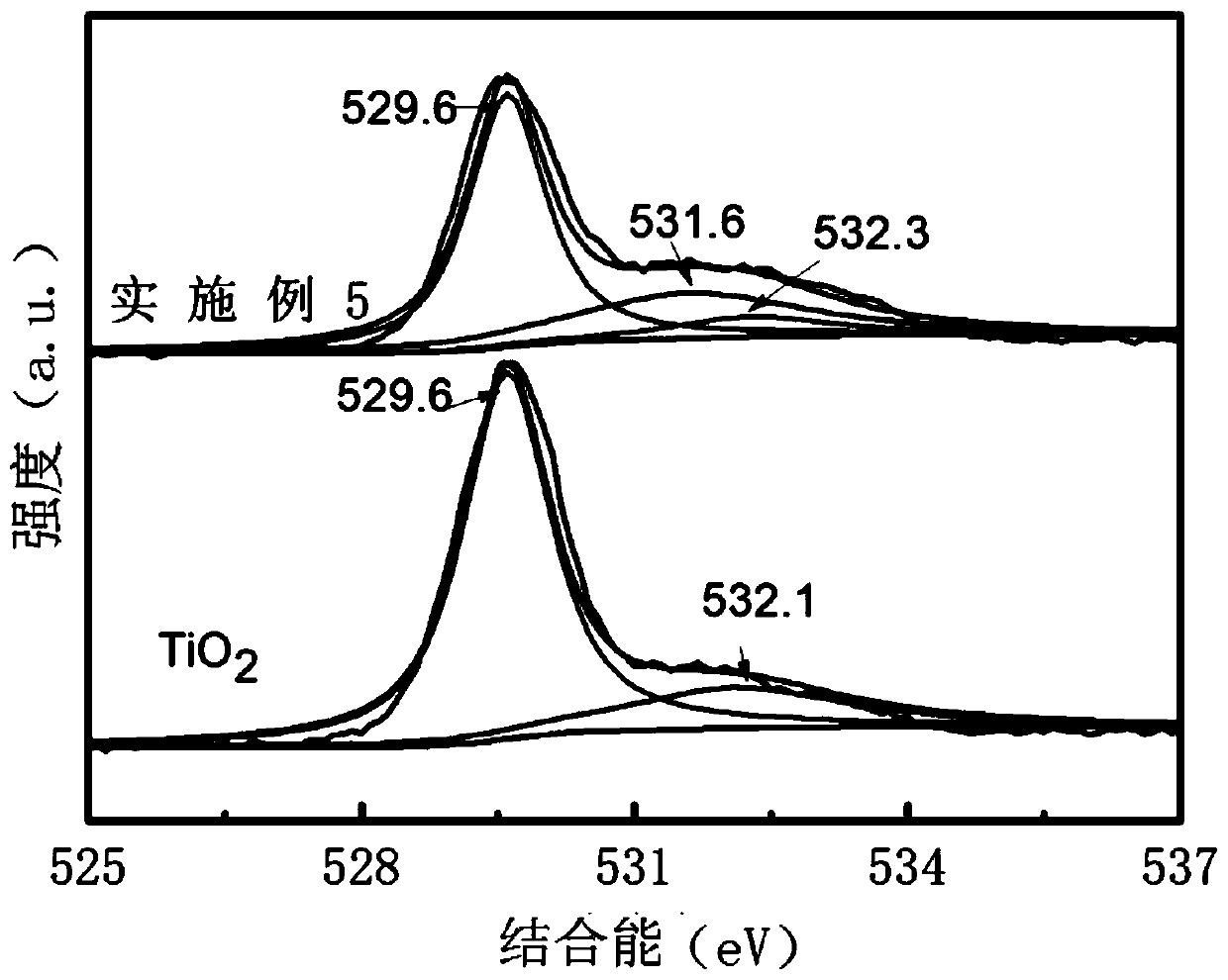

Oxygen-deficient titanium dioxide catalyst as well as preparation method and application thereof

A technology of titanium dioxide and nano-titanium dioxide, applied in the direction of titanium dioxide, titanium oxide/hydroxide, physical/chemical process catalysts, etc., can solve the problems of complex process, unfavorable industrial application, high energy consumption, etc., achieve high degradation rate, novel technology, Experiment with the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the oxygen-deficient titania catalyst of the present invention comprises the following steps:

[0035] a. Uniformly disperse titanium dioxide in the plasma reactor, and pass through the working gas to empty the reactor;

[0036] b. Keep the working gas continuously fed, then turn on the power supply of the plasma reactor, adjust the power supply voltage and current to a stable working state, under the conditions of the plasma reactor voltage of 80-140V and current of 1.35-1.93A, Treat for 20 to 50 minutes. After the treatment, turn off the power first, and then turn off the gas source. After the reactor is cooled to room temperature, an oxygen-deficient nano-titanium dioxide catalyst is obtained;

[0037] Wherein, the working gas is composed of H 2 and N 2 composition.

[0038] The reaction of the present invention is carried out under normal pressure, and the outside of the reaction does not need to be heated.

[0039] Preferably, 0.3-0.6 ...

Embodiment 1

[0059] Step 1: Evenly disperse the weighed 0.3g commercial titanium dioxide P25 in the DBD dielectric barrier discharge cold plasma reactor;

[0060] Step 2: Pass N into the plasma reactor in Step 1 2 -H 2 Mixed gas, the purpose is to evacuate the air in the plasma reactor in step 1, wherein the flow rate of nitrogen-hydrogen mixed gas is 40mL / min, N 2 :H 2 The volume percentage is 99%:1%, and the emptying time is 5 minutes;

[0061] Step 3: Keep N 2 -H 2 Continue to connect in the state of step 2, then turn on the power supply of the DBD cold plasma reactor, and adjust the power supply voltage and current to a stable working state. At this time, the voltage is 100V and the current is 1.58A.

[0062] Step 4: Continue N at step 3 2 -H 2 Under plasma gas atmosphere, process for 30min.

[0063] Step 5: After the treatment, turn off the power first, then turn off the gas source, wait for the reactor to cool down to room temperature, and collect the catalyst.

[0064] Step...

Embodiment 2

[0066] Step 1: Evenly disperse 0.3 g of commercial titanium dioxide P25 in a DBD dielectric barrier discharge cold plasma reactor.

[0067] Step 2: Pass N into the plasma reactor in Step 1 2 -H 2 Mixed gas, the purpose is to evacuate the air in the plasma reactor in step 1, wherein the flow rate of nitrogen-hydrogen mixed gas is 100mL / min, N 2 :H 2 The volume percentage is 95%:5%, and the emptying time is 5 minutes.

[0068] Step 3: Keep N 2 -H 2 Continue to connect in the state of step 2, then turn on the power supply of the DBD cold plasma reactor, and adjust the power supply voltage and current to a stable working state. At this time, the voltage is 100V and the current is 1.58A.

[0069] Step 4: Continue N at step 3 2 -H 2 Under the plasma gas atmosphere, the treatment time of titanium dioxide is 30min.

[0070] Step 5: After the treatment, turn off the power first, then turn off the gas source, wait for the reactor to cool down to room temperature, and collect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com