Dust removal and denitration integrated apparatus for high-temperature flue gas of cement kiln

A high-temperature flue gas and cement kiln technology, which is applied in the field of flue gas treatment, can solve the problems of uneven gas flow velocity in the catalyst layer, low or high flow velocity in the catalyst layer, uneven velocity distribution, etc., and achieve high dust removal and denitrification efficiency. The effect of a wide range of environments and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

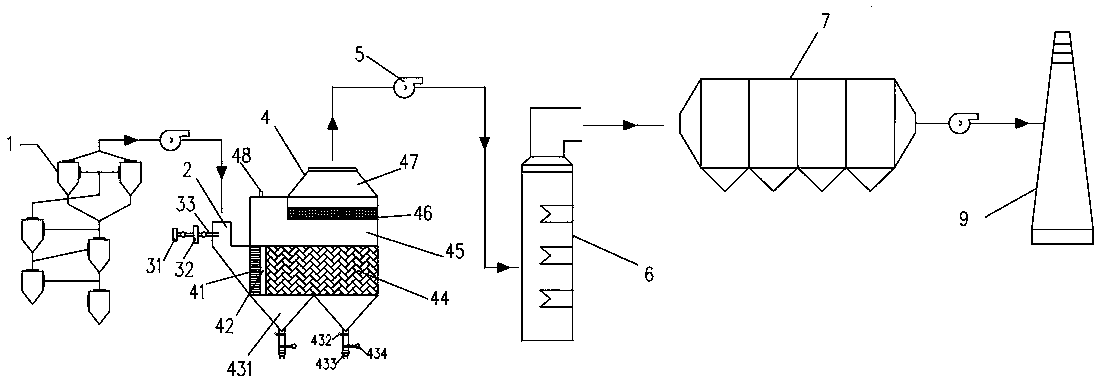

[0019] see figure 1 , a cement kiln high-temperature flue gas dust removal and denitrification integrated device 4 of the present invention, including a preheater 1, a dust removal and denitrification integrated device 4, a waste heat boiler 6, and a dust collector at the end of the pit, which are sequentially connected through pipelines according to the flue gas flow direction 7 and the chimney 9. An induced draft fan 5 is installed between the preheater 1 and the integrated dust removal and denitrification device 4 , between the integrated dust removal and denitrification device 4 and the waste heat boiler 6 , and between the dust collector 7 at the end of the pit and the chimney 9 .

[0020] The left end and the top of the dust removal and denitrification integrated device 4 are respectively provided with an air inlet and an air outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com