Preparation method of intelligent pH response type melamine foam oil-water separation material

A technology for melamine and oil-water separation, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., and can solve problems such as complex pH-responsive foam preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Make the volume 1.5×1.5×2cm 3 The melamine foam was put into 0.16 g of 3-aminopropyltrimethoxysilane dissolved in 32 g of toluene solution and soaked under reflux at 110° C. for 1 hour for silanization modification. After taking it out, it was dried in an oven at 60° C. to constant weight.

[0022] (2) 0.2 g of diethylaminoethyl methacrylate and 0.1 g of copper sulfate were dissolved in 40 g of deionized water to prepare a mixed solution. Add the foam obtained in step (1) into the mixed solution, react at 80°C for 2 hours, take it out, wash it with deionized water and ethanol three times, and then dry it in an oven at 60°C to constant weight to obtain pH-responsive melamine Foam oil-water separation material.

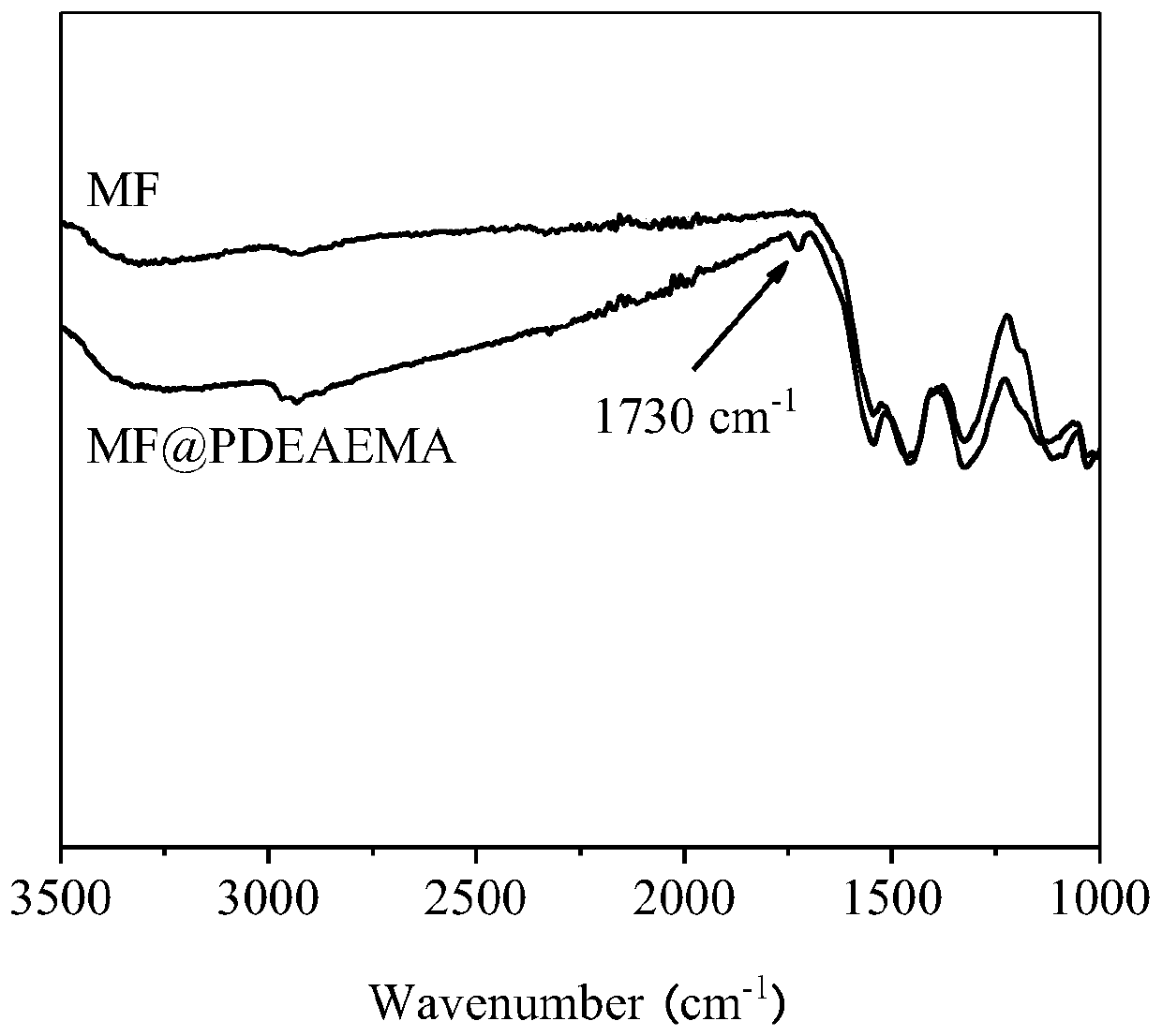

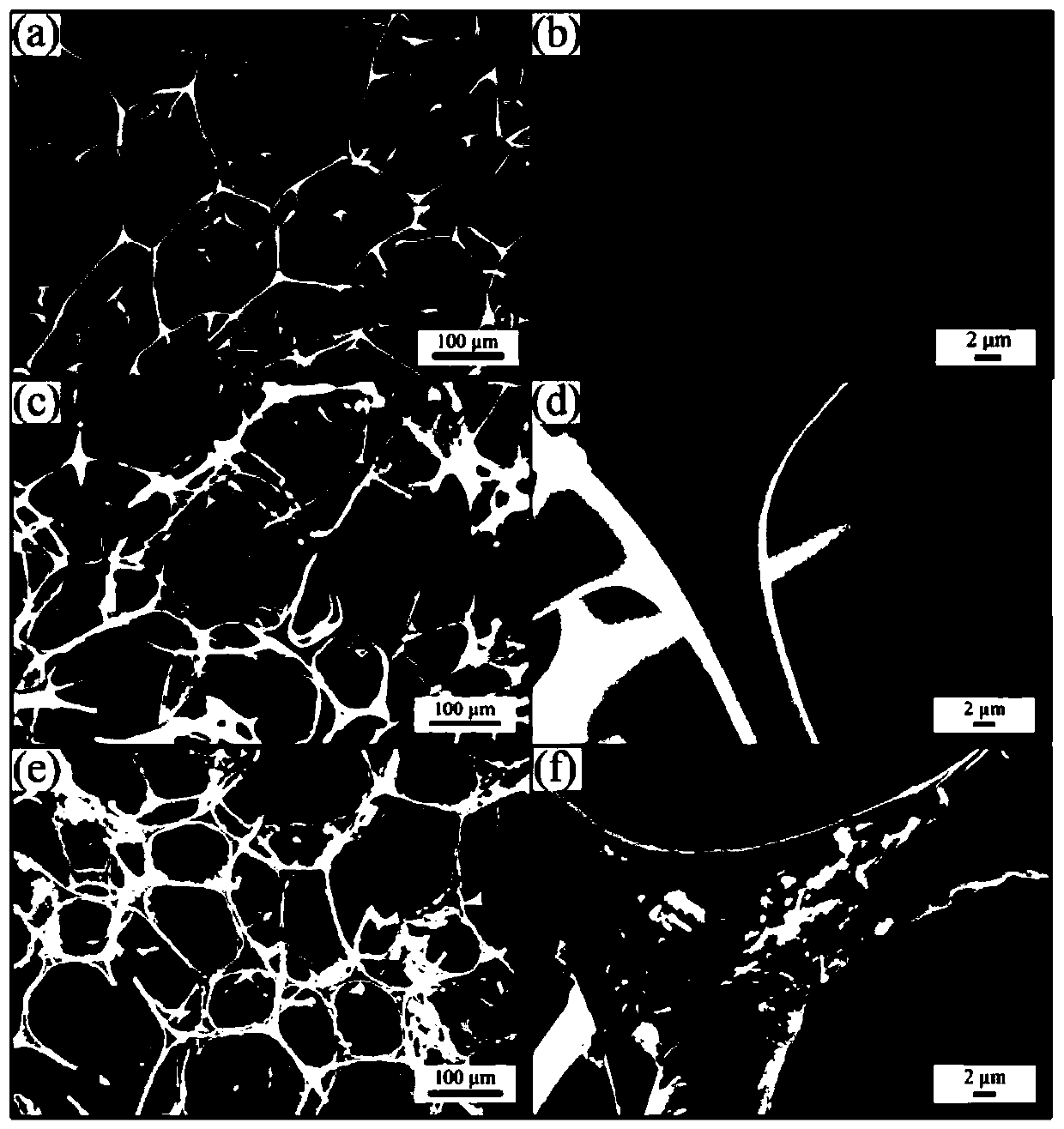

[0023] The obtained oil-water separation materials were characterized. figure 1 It can be seen that compared to the unmodified melamine foam, the modified melamine foam obtained in Example 1 is at 1730cm -1 The stretching vibration peak of the carbonyl gro...

Embodiment 2

[0027] (1) Make the volume 1.5×1.5×2cm 3 Put the melamine foam into 32 g of toluene solution dissolved with 0.4 g of 3-aminopropyltrimethoxysilane and soak it under reflux at 115° C. for 3 hours for silanization modification. After taking it out, dry it in an oven at 60° C. to constant weight.

[0028] (2) 0.4 g of diethylaminoethyl methacrylate and 0.2 g of copper sulfate were dissolved in 40 g of deionized water to prepare a mixed solution. Add the foam obtained in step (1) into the mixed solution, react at 70°C for 2 hours, take it out, wash it with deionized water and ethanol three times, and then dry it in an oven at 60°C to constant weight to obtain pH-responsive melamine Foam oil-water separation material.

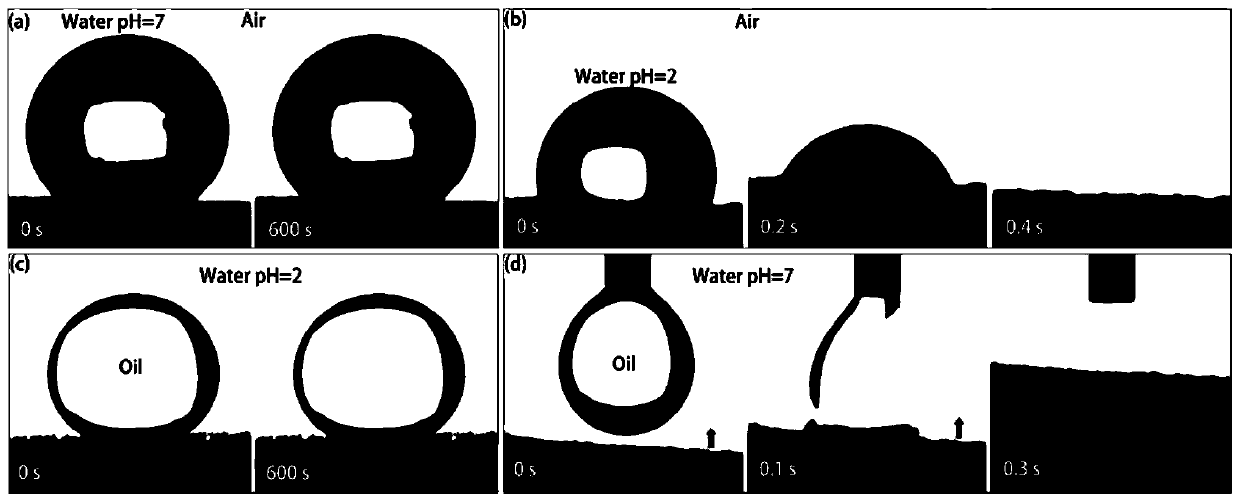

[0029] Test the water contact angle of the foam. When using water with pH=2, the contact angle is 0°; when using water with pH=7, the contact angle is 132°; when using water with pH=9, the contact angle is 134° Spend. Prove that the foam is hydrophilic under acid...

Embodiment 3

[0031] (1) Make the volume 1.5×1.5×2cm 3 The melamine foam was put into 0.6 g of 3-aminopropyltrimethoxysilane dissolved in 32 g of toluene solution and soaked under reflux at 115° C. for 5 hours for silanization modification. After taking it out, it was dried in an oven at 60° C. to constant weight.

[0032] (2) 0.6 g of diethylaminoethyl methacrylate and 0.4 g of copper sulfate were dissolved in 40 g of deionized water to prepare a mixed solution. Add the foam obtained in step (1) into the mixed solution, react at 70°C for 6 hours, take it out, wash it with deionized water and ethanol three times, and then dry it in an oven at 60°C to constant weight to obtain pH-responsive melamine Foam oil-water separation material.

[0033] Test the water contact angle of the foam. When using water with pH=2, the contact angle is 0°; when using water with pH=7, the contact angle is 140°; when using water with pH=9, the contact angle is 142° Spend. Prove that the foam is hydrophilic und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com