Anti-pollution calcium carbonate-based cellulose composite membrane as well as preparation method and application thereof

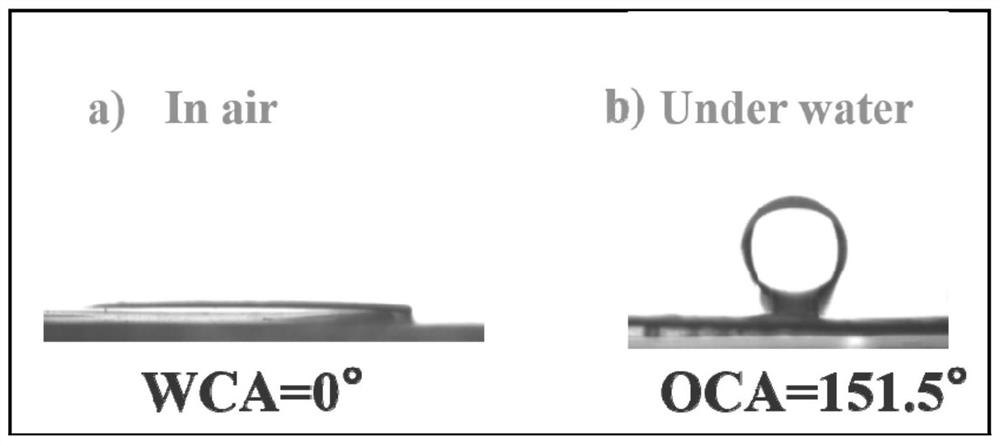

A cellulose-based and composite membrane technology, which is applied in the field of material chemistry, can solve the problems that the surface of the membrane is easily adhered by oil, limits the application of membrane separation technology, and reduces performance and life. Effect of Pollution Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] S1. Preparation of GO / CMC / CaCl 2 mixture

[0039] The preparation concentration is 0.1mol / L calcium chloride CaCl 2aqueous solution and 0.1 wt% sodium carboxymethylcellulose (CMC) aqueous solution. Add 0.5mL graphene oxide dispersion to 50mL CMC aqueous solution (dilute 1mL GO to 10mL, then take 0.5mL, the concentration of GO dispersion is 0.05mg / mL at this time), under vigorous stirring, dissolve 50mL CaCl 2 The solution was added to the above-mentioned CMC solution containing GO (reacted for about 10min), and GO / CMC / CaCl was prepared. 2 Mixture.

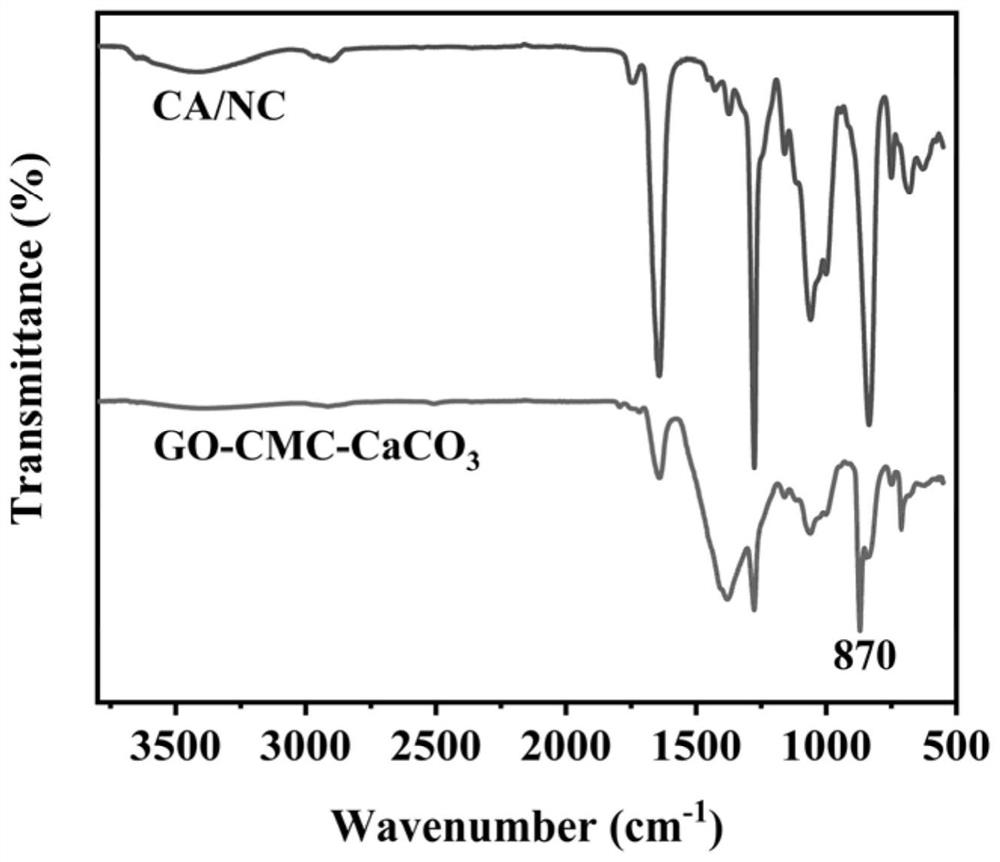

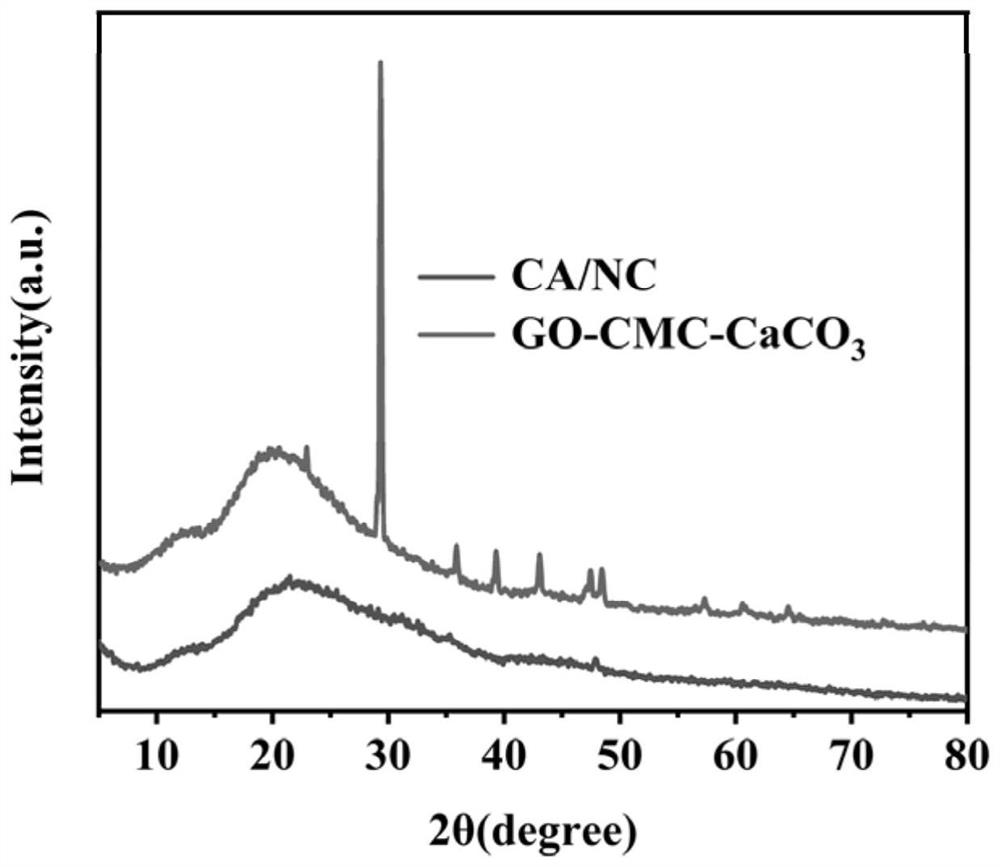

[0040] S2. Preparation of GO-CMC-CaCO 3 Composite film

[0041] Prepare 5 mL of Na with a concentration of 0.1 mol / L 2 CO 3 solution, take 5mL GO / CMC / CaCl 2 The mixture was diluted to 10mL, and the above Na 2 CO 3 The solution was added to the diluted GO / CMC / CaCl 2 In the mixed liquid, stir and react for 20s, then use the mixed acid fiber membrane (pore size: 0.22 μm) as the base, and filter the above suspension t...

Embodiment 2

[0043] S1. Preparation of GO / CMC / CaCl 2 mixture

[0044] The preparation concentration is 0.08mol / L calcium chloride CaCl 2 aqueous solution and 0.08 wt% sodium carboxymethylcellulose (CMC) aqueous solution. Add 0.4mL graphene oxide dispersion to 45mL CMC aqueous solution (dilute 1mL GO to 10mL, then take 0.4mL, at this time the concentration of GO dispersion is 0.05mg / mL), 45mL CaCl 2 The solution was added to the above-mentioned CMC solution containing GO (reacted for about 10min), and GO / CMC / CaCl was prepared 2 Mixture.

[0045] S2. Preparation of GO-CMC-CaCO 3 Composite film

[0046] Prepare 4 mL of Na with a concentration of 0.09 mol / L 2 CO 3 solution, take 4mL GO / CMC / CaCl 2 The mixture was diluted to 10mL, and the above Na 2 CO 3 The solution was added to the diluted GO / CMC / CaCl 2 In the mixed liquid, stir and react for 20s, then use the mixed acid fiber membrane (pore size: 0.22 μm) as the base, and filter the above suspension to prepare a composite membrane....

Embodiment 3

[0048] S1. Preparation of GO / CMC / CaCl 2 mixture

[0049] The preparation concentration is 0.12mol / L calcium chloride CaCl 2 aqueous solution and 0.12 wt% sodium carboxymethylcellulose (CMC) aqueous solution. Add 0.6mL graphene oxide dispersion to 55mL CMC aqueous solution (dilute 1mL GO to 10mL, then take 0.6mL, at this time the concentration of GO dispersion is 0.05mg / mL), under vigorous stirring, dissolve 55mL CaCl 2 The solution was added to the above-mentioned CMC solution containing GO (reacted for about 10min), and GO / CMC / CaCl was prepared. 2 Mixture.

[0050] S2. Preparation of GO-CMC-CaCO 3 Composite film

[0051] Prepare 5 mL of Na with a concentration of 0.11 mol / L 2 CO 3 solution, take 6mL GO / CMC / CaCl 2 The mixture was diluted to 10mL, and the above Na 2 CO 3 The solution was added to the diluted GO / CMC / CaCl 2 In the mixed liquid, stir and react for 20s, then use the mixed acid fiber membrane (pore size: 0.22 μm) as the base, and filter the above suspensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com