A method for rapid rehydration of textured protein

A protein and fast technology, applied in protein food ingredients, protein food processing, food science, etc., can solve the problems of soft and rotten textured protein surface, lower textured protein quality, uneven water distribution, etc., to save rehydration time , Rehydration time is shortened, and the water diffusion speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for rapid rehydration of textured protein, specifically as follows:

[0055] (1) Preparation of plant textured protein: 9 kg of wheat protein, 1 kg of wheat starch and 100 g of sodium bicarbonate were weighed, placed in a solid stirrer and mixed evenly. Add the mixed material into the feeding barrel of the twin-screw extruder. The feed rate is 20kg / h, the screw speed is 270rpm, and the liquid feed rate is 40%. Set the temperature of different zones in the screw sleeve as: 60°C, 90°C, 130°C, 170°C and 140°C. After the output is stable, the textured protein is collected and cut into long strips. Put the textured protein into the fluidized bed for drying, the drying temperature is 60°C, and the drying time is 6h. Under this process condition, the obtained textured protein has a good structure, and the moisture content is lower than 20%.

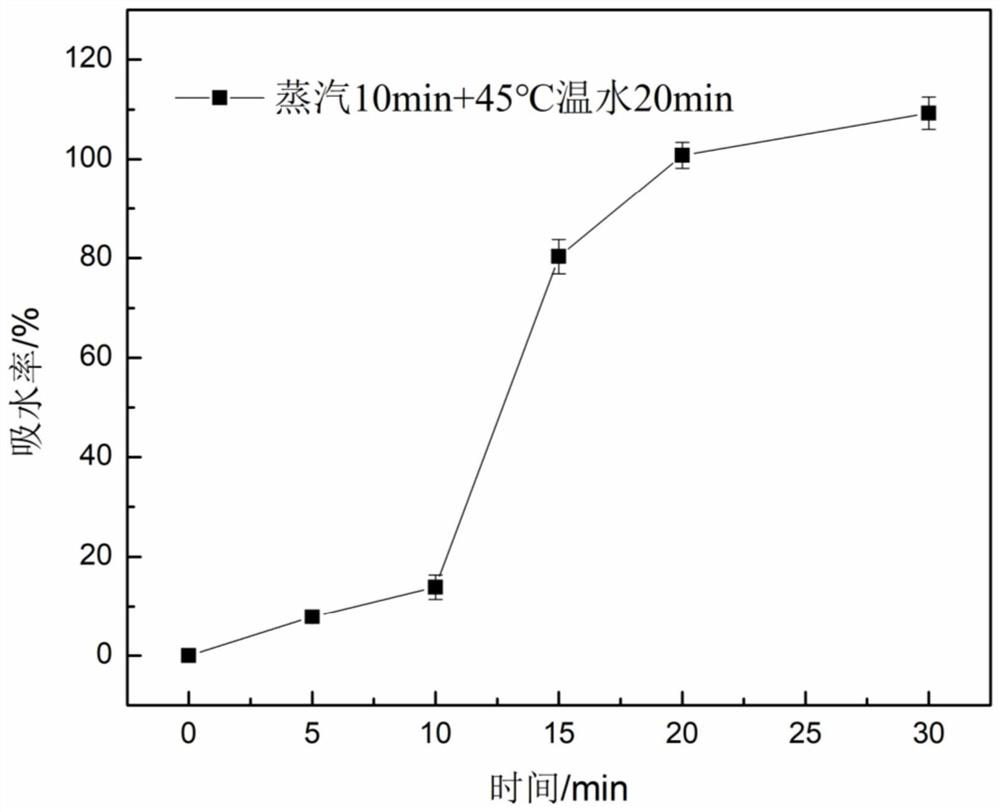

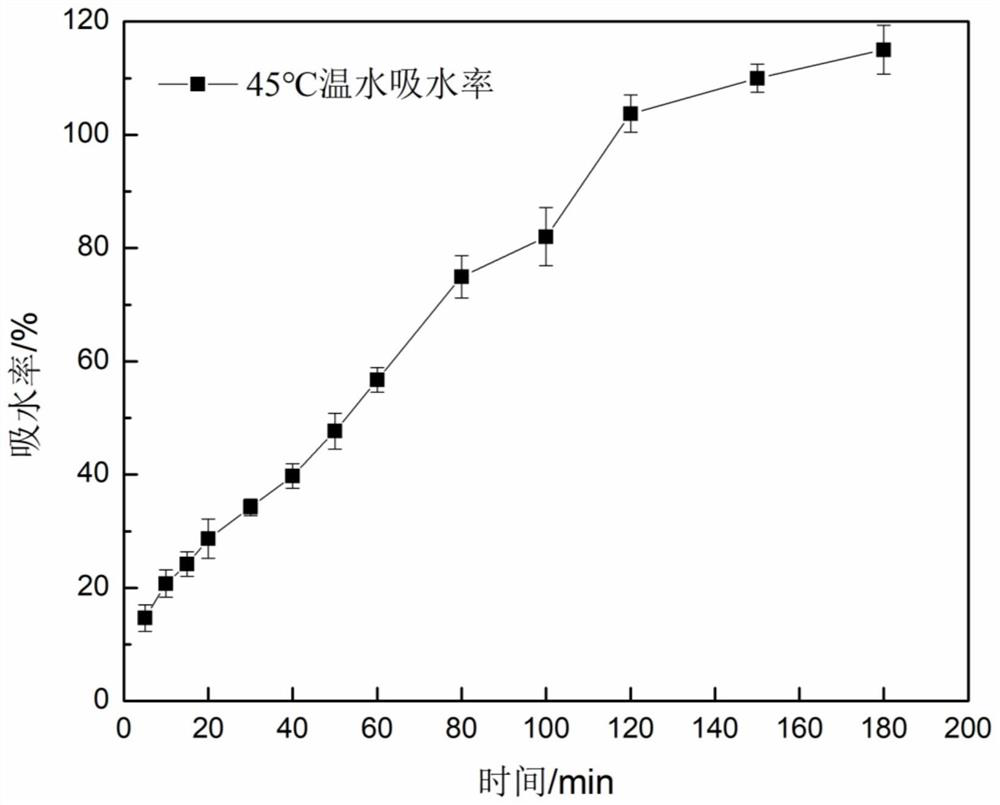

[0056] (2) Steam softening of the textured protein: place the above-mentioned textured protein in a steamer, and steam at 1...

Embodiment 2

[0061] A method for rapid rehydration of textured protein, specifically as follows:

[0062] (1) Preparation of plant textured protein: Weigh 10kg of soybean protein and 100g of monascus red pigment, put them in a solid mixer and mix them evenly. Add the mixed material into the feeding barrel of the twin-screw extruder. The feed rate is 13kg / h, the screw speed is 220rpm, and the liquid feed rate is 40%. Set the temperature of different zones in the screw sleeve as: 60°C, 90°C, 130°C, 150°C and 140°C. After the output is stable, the textured protein is collected and cut into long strips. Put the textured protein into the fluidized bed for drying, the drying temperature is 60°C, and the drying time is 6h. Under this process condition, the obtained textured protein has a good textured structure, and the moisture content is lower than 20%.

[0063] (2) Steam softening of the textured protein: place the above-mentioned textured protein in a steamer, and steam at 100° C. for 20 ...

Embodiment 3

[0068] A method for rapid rehydration of textured protein, specifically as follows:

[0069] (1) Preparation of plant textured protein: Weigh 9 kg of pea protein, put it in a solid mixer and mix it evenly. Add the mixed material into the feeding barrel of the twin-screw extruder. The feed rate is 20kg / h, the screw speed is 220rpm, and the liquid feed rate is 40%. Set the temperature of different zones in the screw sleeve as: 60°C, 90°C, 130°C, 170°C and 140°C. After the output is stable, the textured protein is collected and cut into long strips. Put the textured protein into the fluidized bed for drying, the drying temperature is 60°C, and the drying time is 6h. Under this process condition, the obtained textured protein has a good textured structure, and the moisture content is lower than 20%.

[0070] (2) Steam softening of the textured protein: place the above-mentioned textured protein in a steamer, and steam at 100° C. for 20 minutes.

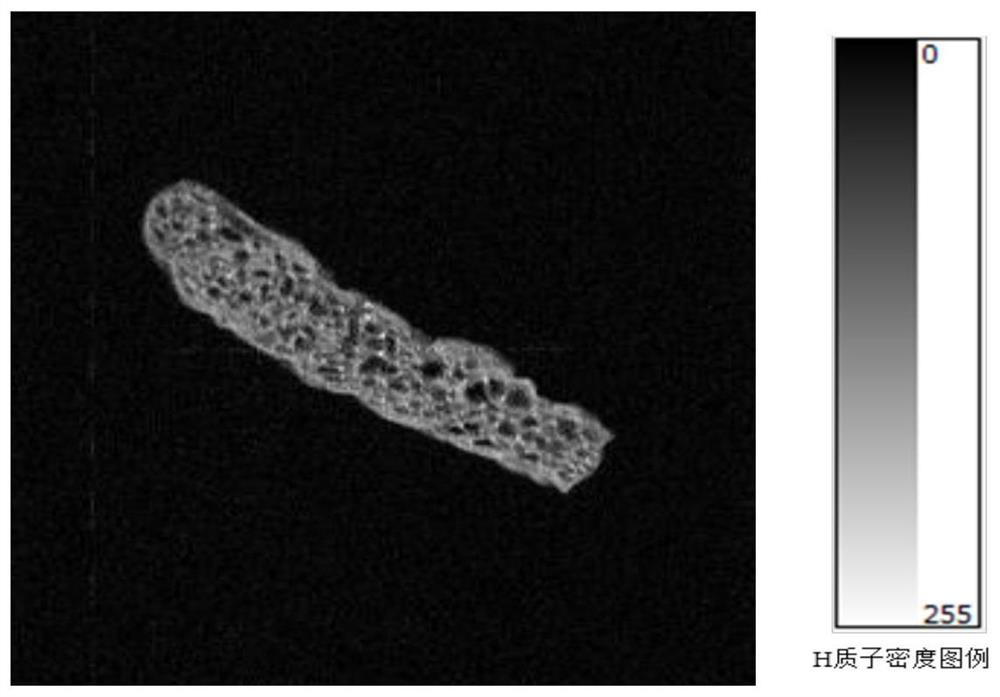

[0071] (3) Rehydration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com