A high-speed drive motor shaft for new energy vehicles and its manufacturing process

A new energy vehicle, motor shaft technology, applied in shafts, couplings, mechanical equipment and other directions, can solve the problems of inconvenient assembly and disassembly of motor shafts, poor heat dissipation effect, etc. Strong pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

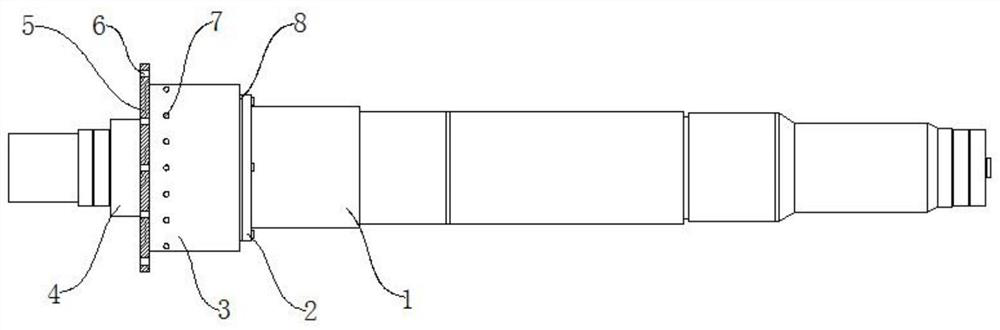

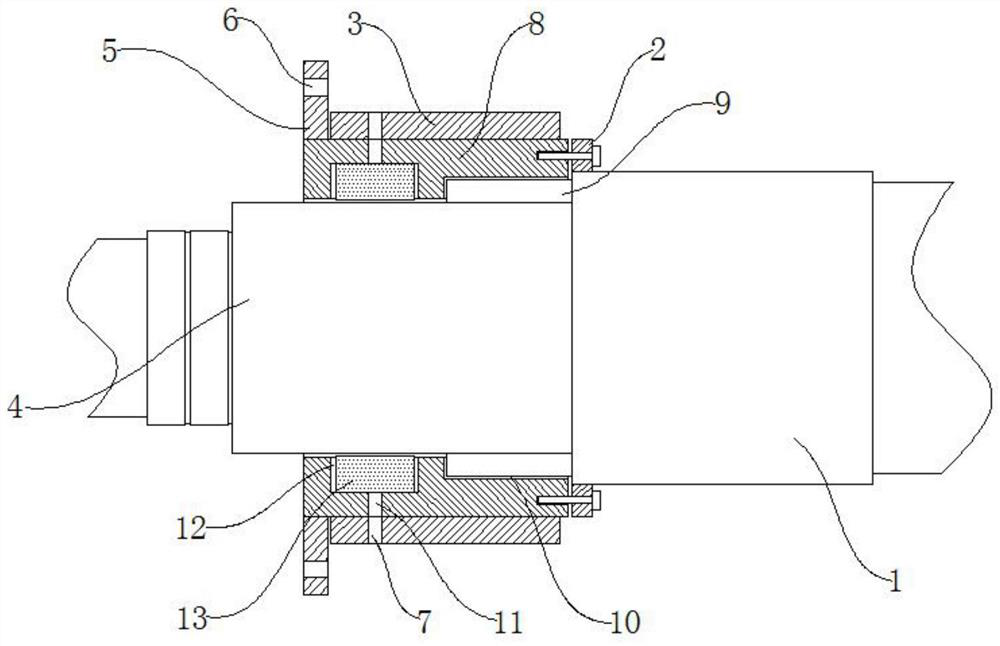

[0030] refer to Figure 1-4 , a high-speed drive motor shaft for new energy vehicles, including a first main shaft 1 and a second main shaft 4, the first main shaft 1 and the second main shaft 4 are fixedly connected, and one end on the outer wall of the first main shaft 1 is fixedly connected to a limited position Ring 2, the limit ring 2 close to the second main shaft 4 is fixedly connected with a shaft sleeve 8 by several screws, and the shaft sleeve 8 is set on the second main shaft 4. Through this design, the motor shaft can be quickly and conveniently The shaft sleeve is fixedly assembled on the motor shaft, and the motor shaft sleeve can be easily disassembled, which greatly facilitates the assembly process between the motor shaft main shaft and the shaft sleeve, and the assembly structure is stable and reliable. The stability during the rotating operation of the motor shaft can be improved.

[0031] Two key grooves 10 are provided on the inner wall of the bushing 8 cl...

Embodiment 2

[0033] refer to figure 2 and Figure 4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the heat dissipation mechanism includes a groove 12, the groove 12 is set on the inner wall of the shaft sleeve 8, and a plurality of heat dissipation The fins 13 and the inner bottom of the groove 12 are evenly provided with several second heat dissipation channels 11, and the several second heat dissipation channels 11 are respectively connected to the several first heat dissipation channels 7, and the groove 12 is a groove of an annular structure , and a plurality of cooling fins 13 are annularly fixedly connected inside the groove 12, and several second heat dissipation channels 11 are circumferentially opened at the bottom of the groove 12. Through this design, it is possible to effectively The effect of cooling the motor shaft is achieved. The heat generated during the rotation and operation of the motor shaft will quickly and sequ...

Embodiment 3

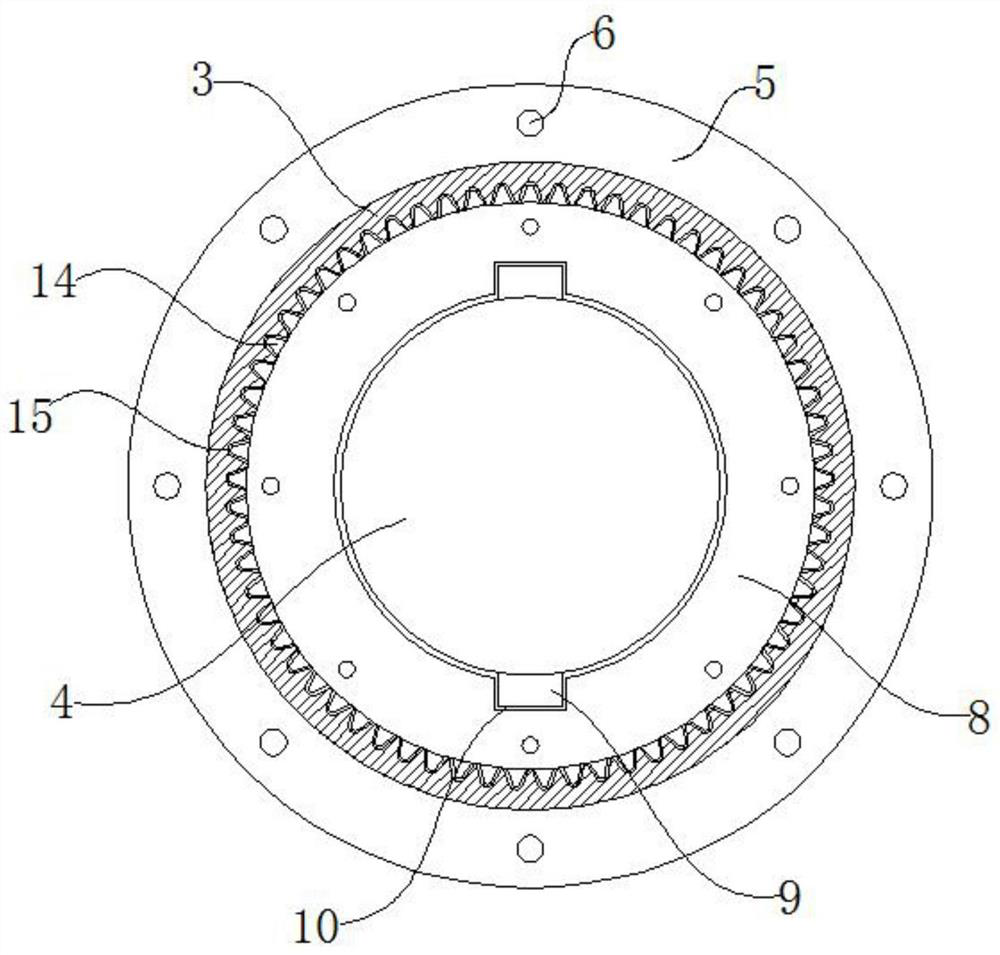

[0035] refer to image 3, as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the clamping mechanism includes an annular clamping strip 14 and an annular clamping groove 15, the annular clamping strip 14 is fixedly connected on the outer side wall of the shaft sleeve 8, and the annular clamping The groove 15 is set on the inner side wall of the protective cover 3, and the annular clamping strip 14 and the annular clamping groove 15 are compatible with each other. The annular clamping strip 14 is a ring-shaped sawtooth-shaped structural member, and the annular clamping groove 15 is an annular sawtooth-shaped groove. , and the ring clip 14 and the ring clip groove 15 are engaged with each other. Through this design, the protective sleeve 3 and the shaft sleeve 8 can be connected together more firmly, and the protective sleeve 3 can be better Play a protective role to the shaft sleeve 8.

[0036] The present invention also provides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com